A linear slide grinding device

A technology of linear slide rail and grinding head, which is applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., which can solve the problems of grinding and height adjustment, and achieve the effects of reducing production costs, fixing firmly, and using safely and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

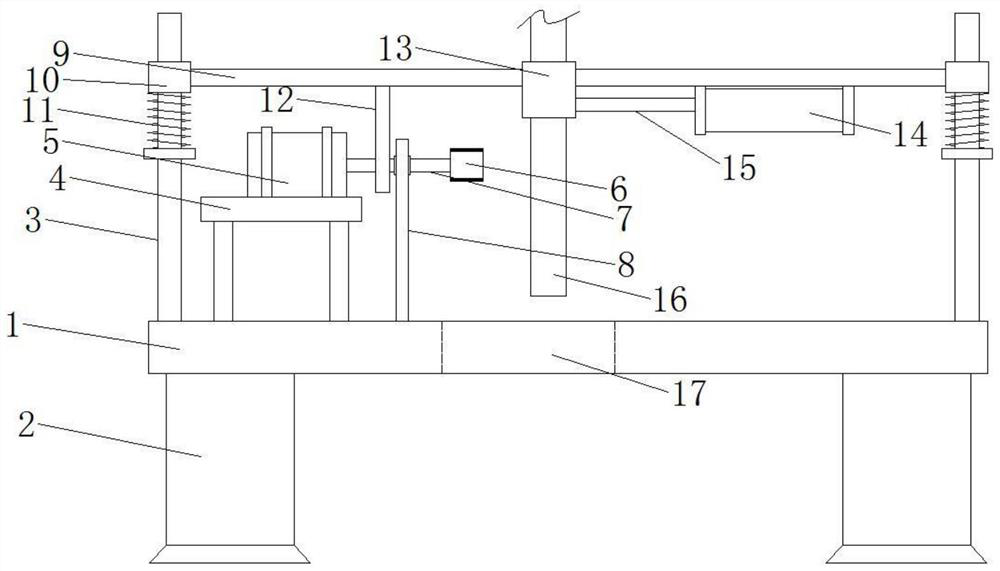

[0023] Please refer to the figure, in the embodiment of the present invention, a linear slide rail grinding device includes an operating table 1, a leg 2, a support rod 3, a motor frame 4, a grinding motor 5 and a grinding head 6; the leg 2 is fixed on The lower side of the operating table 1 is used to support the operating table 1; the motor frame 4 is fixedly installed on the upper surface of the operating table 1, and the motor frame 4 is fixedly installed with a horizontal leftward grinding motor 5. A horizontal transmission shaft 7 is coaxially fixed on the output shaft, and a grinding head 6 is installed on the other end of the transmission shaft 7, and the grinding head 6 is driven to rotate through the rotation of the grinding motor 5 to realize grinding in the groove of the linear slide rail; The shaft 7 is sleeved with a support base 8 fixed on the console 1, and the transmission shaft 7 is connected to the support base 8 through bearings to support the stable rotatio...

Embodiment 2

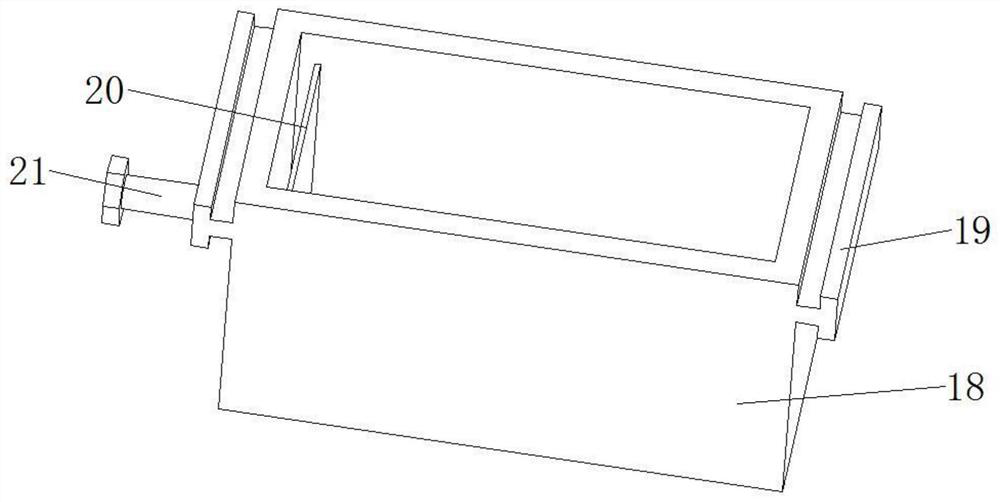

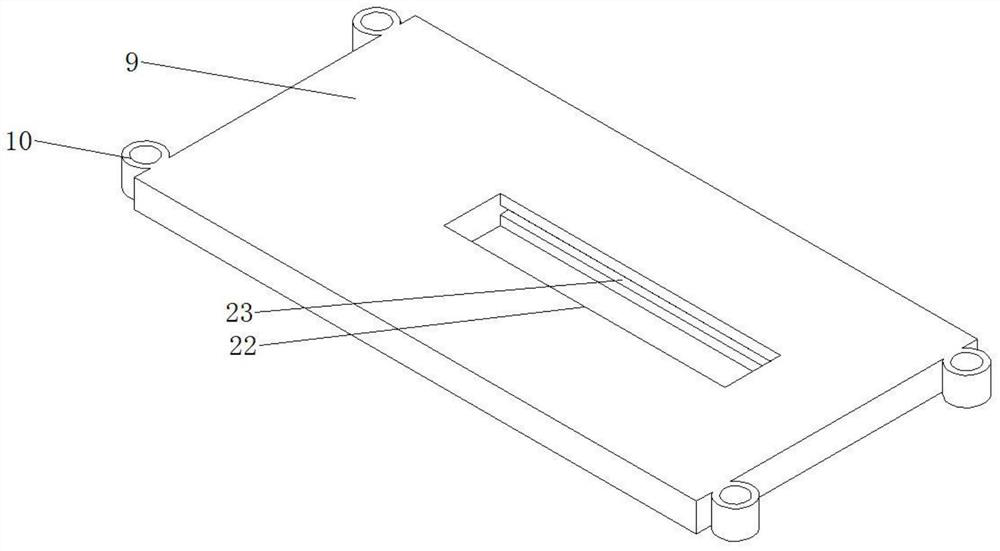

[0027] On the basis of Embodiment 1, the clamping mechanism on the adjustment mechanism 13 includes a clamping bolt 21 threaded on the side wall of the adjustment mechanism 13, and the clamping bolt 21 passes through the side wall of the adjustment mechanism 13 and extends into the Inside it, on the end of the clamping bolt 21, a splint 20 in the vertical direction is rotatably connected. There is a gap between the edge of the splint 20 and the side wall of the adjustment mechanism 13, and the distance is 1-3mm. The tightening bolt 21 is fixedly clamping the linear slide rail 16 to be polished in the adjustment mechanism 13, so as to avoid falling off during the grinding process. It wreaks havoc. On the corresponding operating platform 1 directly below the moving opening 22, there is an opening 17 that runs through the upper and lower sides. The length of the opening 17 is equal to that of the moving opening 22, so that the linear slide rail 16 to be polished placed above pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com