Metal mask frame surface burr removing equipment

A metal mask and burr removal technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding racks, etc., can solve the problems of general grinding efficiency, achieve the effect of convenient grinding and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

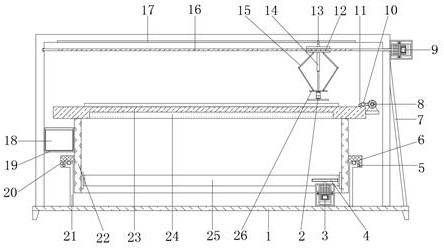

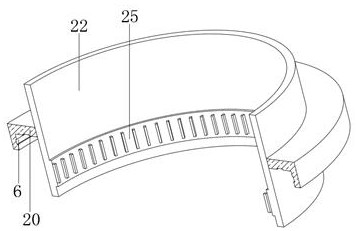

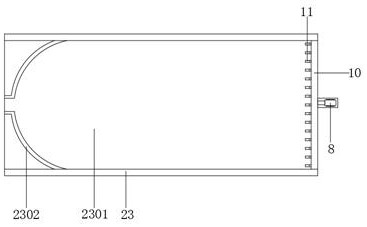

[0028] refer to Figure 1-4 , a metal mask frame surface burr removal equipment, including a base plate 1, the top outer wall of the base plate 1 is fixed with a ring support plate 21 by bolts, it is characterized in that a driven drum 22 is arranged on the top of the support ring plate 21, and The outer wall of the middle end of the driven drum 22 is welded with a side ring plate 20, and the opposite side of the side ring plate 20 and the support ring plate 21 is provided with an annular groove 6, and the inner walls of the corresponding two annular grooves 6 are rollingly connected with etc. The distance distribution balls 5, the top outer wall of the ring support plate 21 is fixed with a platen 23 by bolts, and the bottom outer wall of the platen 23 has a mounting groove, the inner wall of the mounting groove is fixed with an electromagnet 24 by bolts, and the top outer wall of the bottom plate 1 The mounting end frame is fixed by bolts, and the end of the mounting end fram...

Embodiment 2

[0040] refer to Figure 1-4, a metal mask frame surface burr removal method, which uses a metal mask frame surface burr removal equipment, the device includes a base plate 1, the top outer wall of the base plate 1 is fixed with a ring support plate 21 by bolts, and the ring support plate The top of 21 is provided with a driven drum 22, and the outer wall of the middle end of the driven drum 22 is welded with a side ring plate 20, and the opposite side of the side ring plate 20 and the ring support plate 21 is provided with an annular groove 6, and Corresponding to the inner walls of the two annular grooves 6, there are balls 5 distributed equidistantly in rolling connection. The top outer wall of the support ring plate 21 is fixed with a platen 23 by bolts, and the bottom outer wall of the platen 23 is provided with a mounting groove, and the inner wall of the mounting groove passes through Bolts are fixed with electromagnet 24, and the top outer wall of bottom plate 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com