Cutter suction dredger with improved structure

A cutter suction dredger, improved structure technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of low working efficiency of the reamer and achieve improved dredge suction Efficiency, prevention of being blocked, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

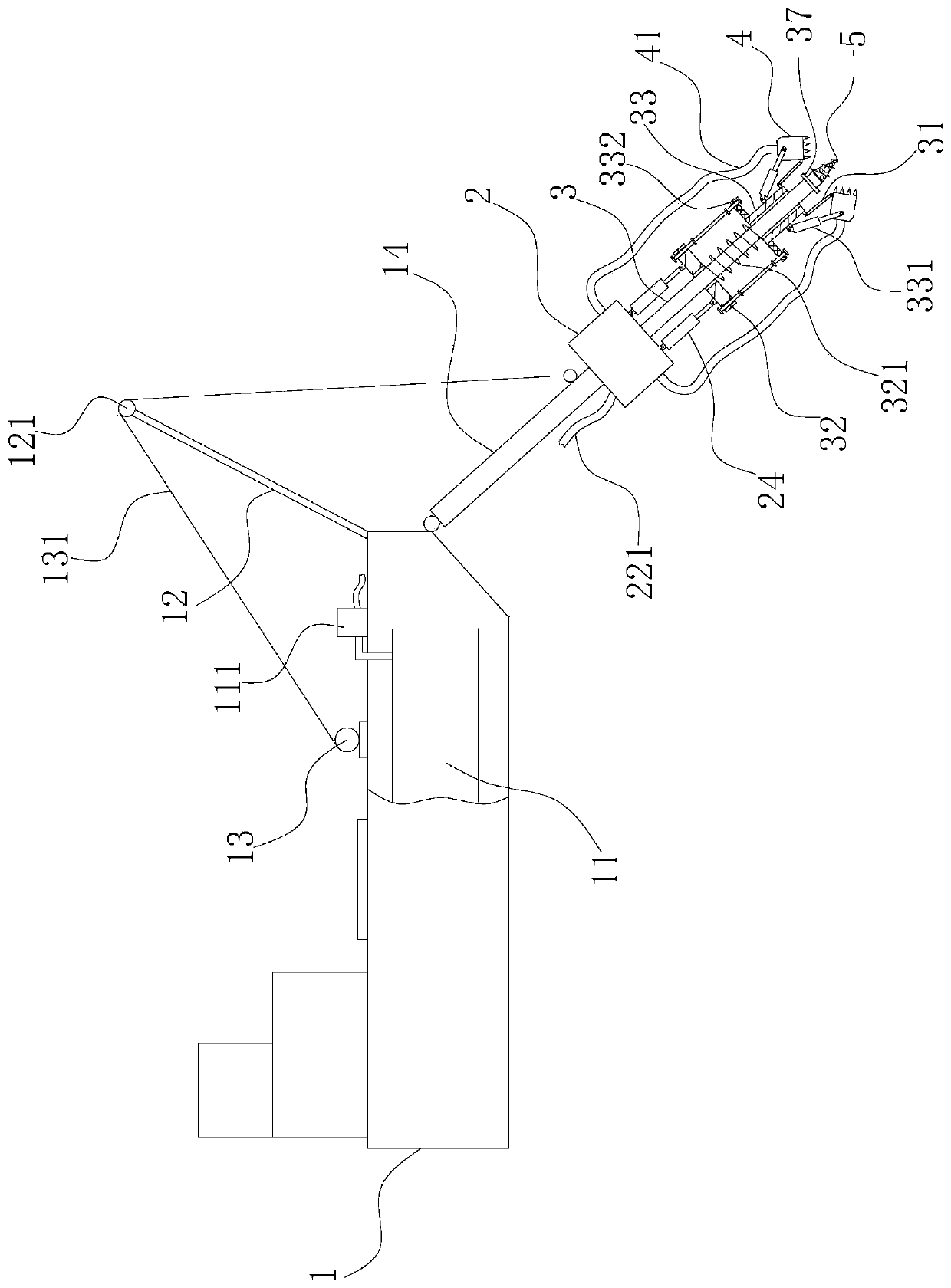

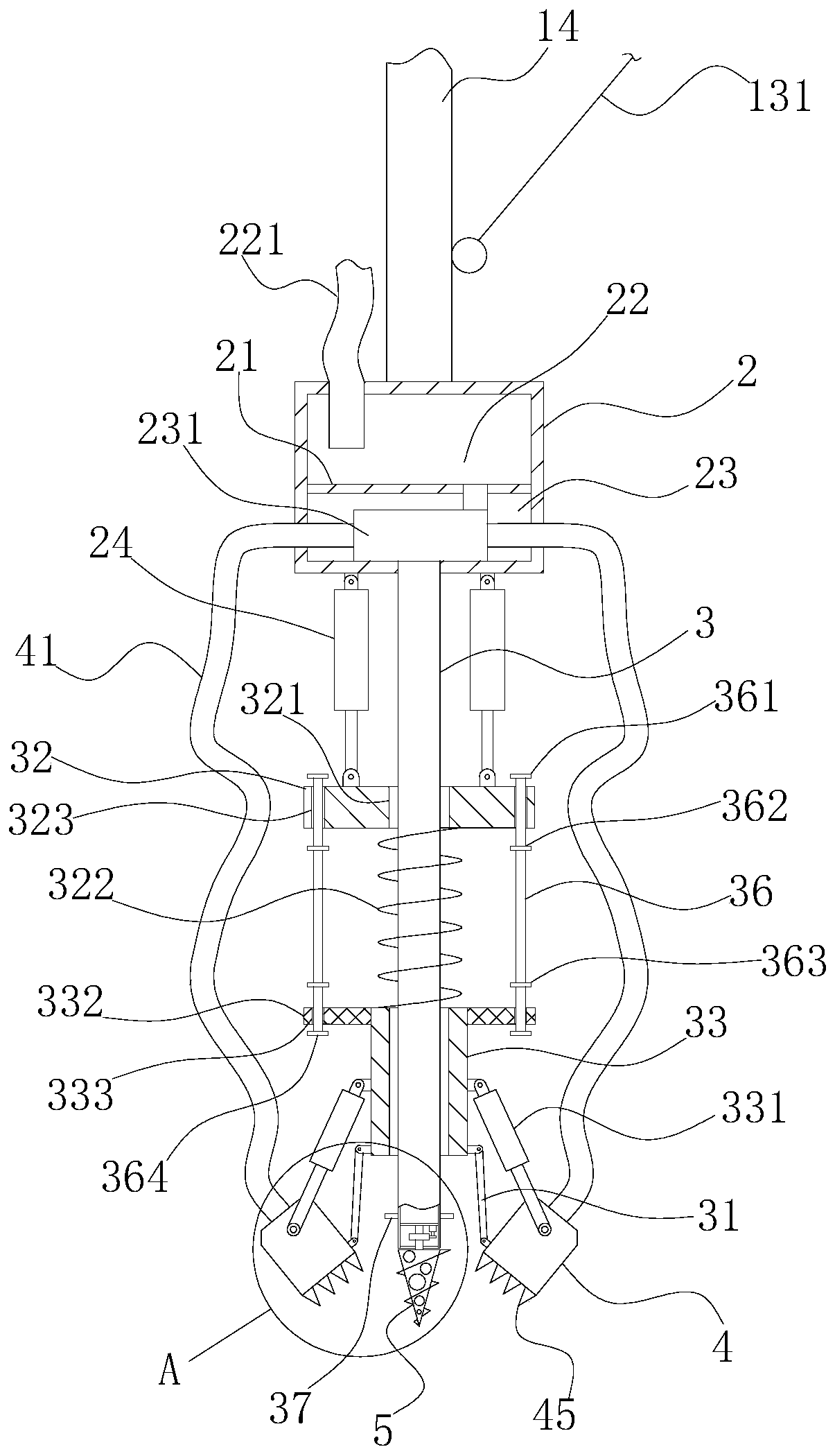

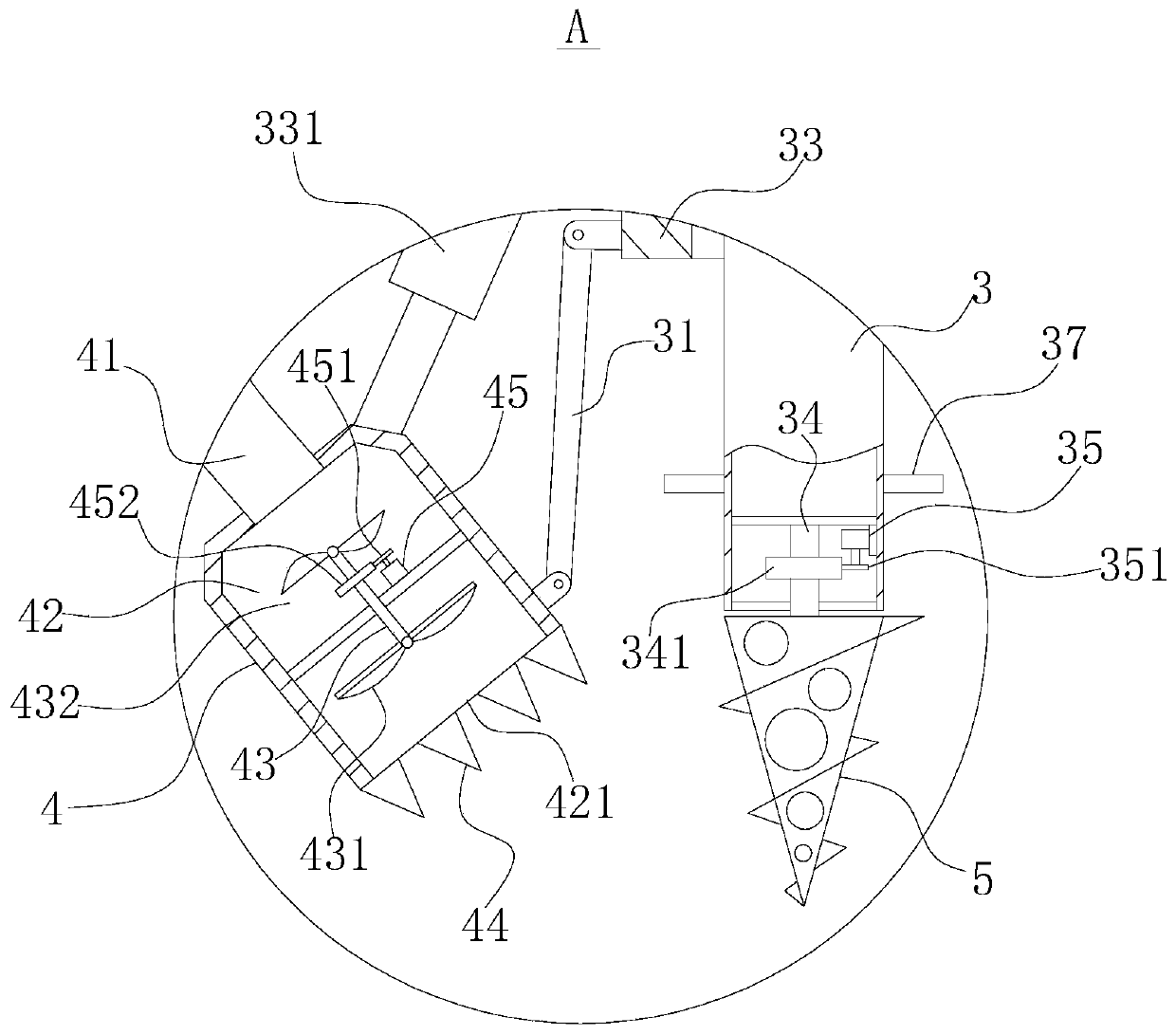

[0035] like Figures 1 to 3 As shown, a cutter suction dredger with an improved structure includes: a hull structure 1, a rotating rod 14, an installation box 2, a mud delivery pipe 3 and a driving mechanism.

[0036] The hull structure 1 is provided with a mud storage compartment 11, and the hull structure 1 is provided with a first dredge pump 111, and the outlet of the first dredge pump 111 communicates with the mud storage compartment 11 through a pipe. The bow of the structure 1 is fixed with a support frame 12, and the top of the support frame 12 is provided with a pulley 121. The hull structure 1 is also provided with an electric winch 13, and a steel wire rope 131 is wound on the reel of the electric winch 13.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com