Vibration damping and noise reducing mechanism for motor rotor

A motor rotor, vibration and noise reduction technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc. problem, to achieve the effect of impact noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

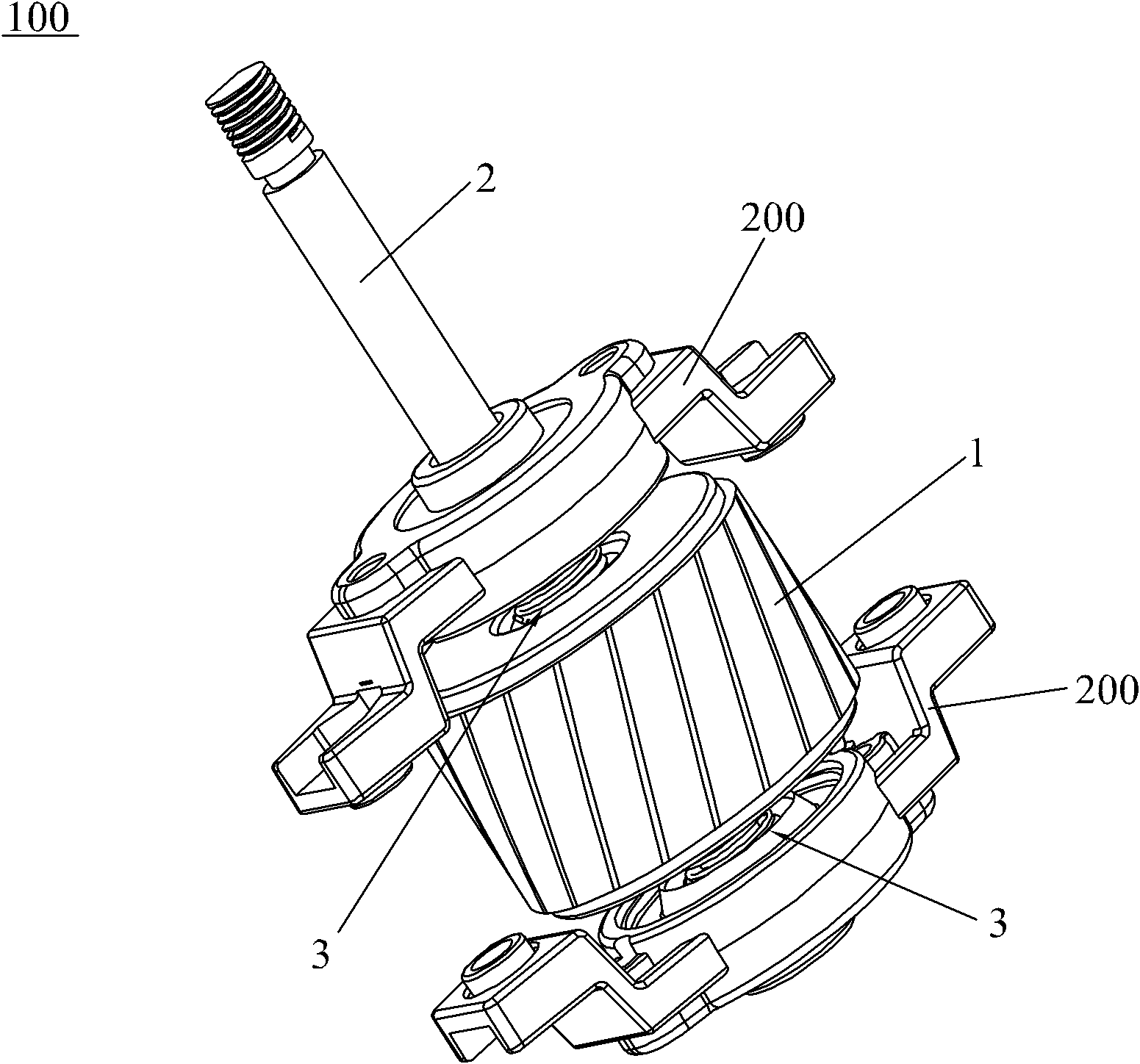

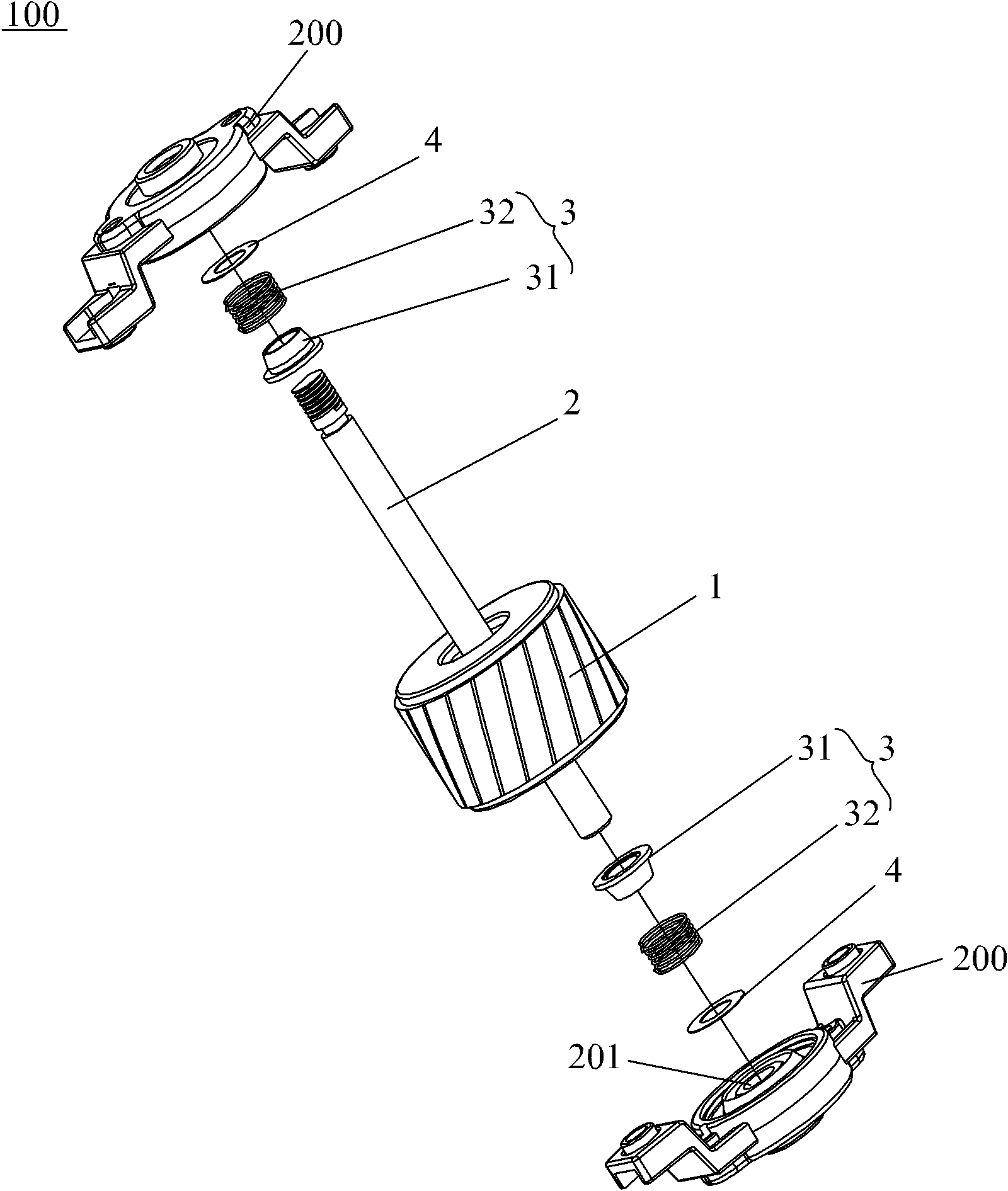

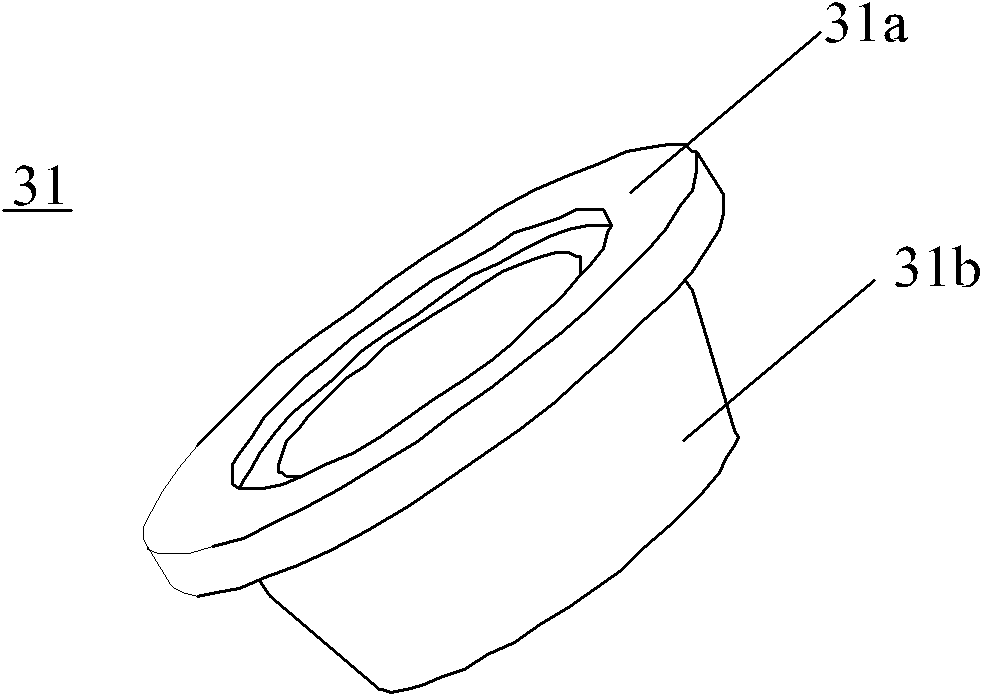

[0015] Such as figure 1 , figure 2 and image 3 As shown, the motor rotor vibration and noise reduction mechanism 100 of the present invention is installed between the end faces of the two bearings 201 of the rotor bracket 200 and a stator (not shown in the figure) to form a motor, including a rotor 1 and a rotating shaft 2. The rotor 1 and the The rotating shaft 2 is sleeved and fixed, the rotating shaft 2 is pivotally connected to the bearing 201 and one end passes through the bearing 201 to form an output shaft, and the motor rotor vibration and noise reduction mechanism 100 also includes a vibration reduction device 3 and The plastic gasket 4, the vibration damping device 3 is respectively arranged symmetrically between the rotor 1 and the end face of the bearing 201, including a retaining ring 31 and a compression spring 32, and the retaining ring 31 has a stepped structure and is socketed The rotating shaft 2 includes a conflicting portion 31a and a socket portion 31b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com