Aluminum alloy lateral protection fence for vehicle

A side guardrail, aluminum alloy technology, applied in the direction of the bumper, etc., can solve the problems of no impact resistance and buffer structure, can not alleviate the impact force, increase the energy consumption of the vehicle, etc., to achieve light weight, ease the impact force, Reduce the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

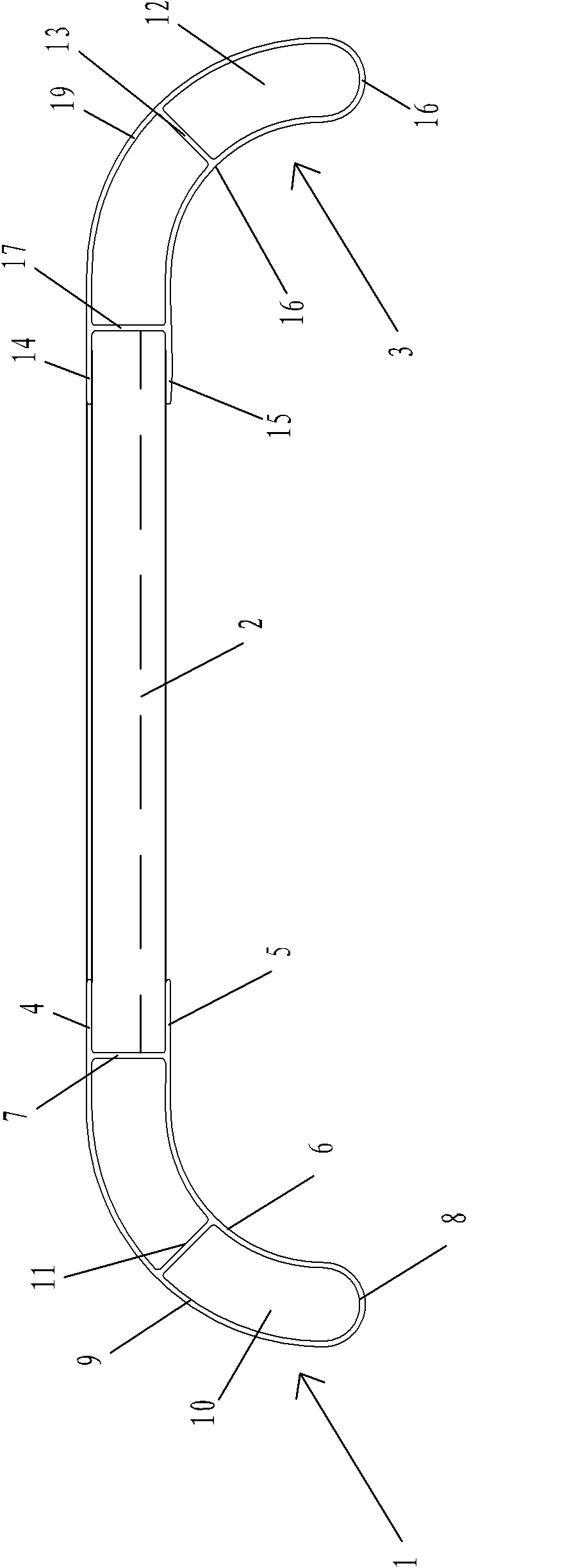

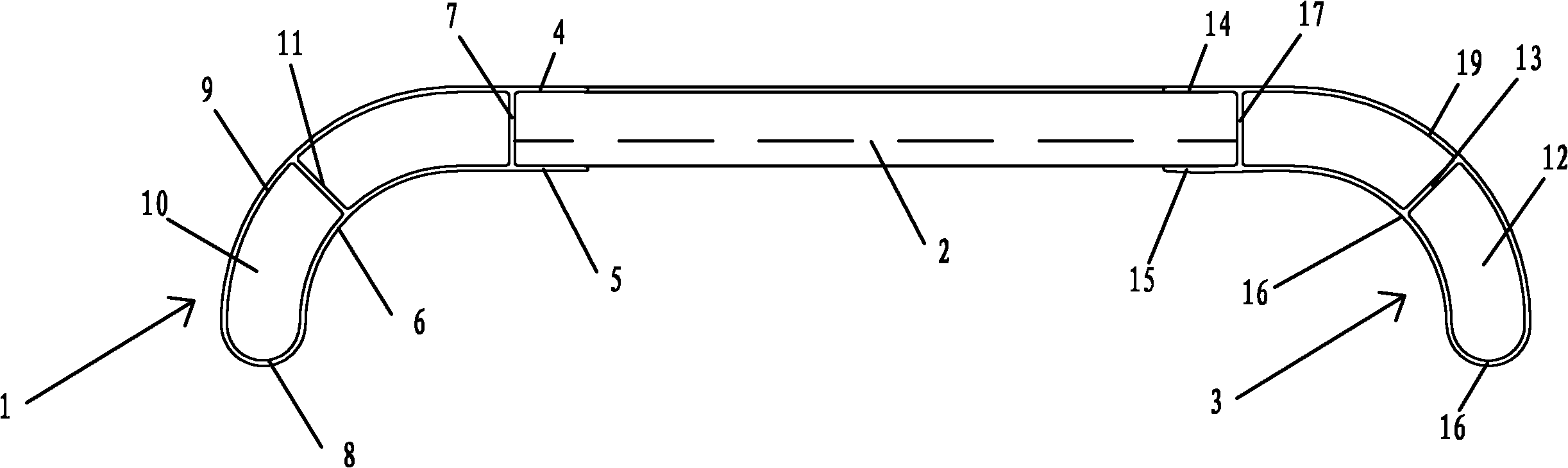

[0011] see figure 1 , the aluminum alloy side guardrail for vehicles of the present invention comprises a front curved beam 1 made of extruded aluminum alloy, a hollow connecting beam 2 made of extruded aluminum alloy and a rear curved beam made of extruded aluminum alloy. The beam 3 and the front curved beam 1 include the front top plate 4 and the front bottom plate 5, the front top plate 4 and the front bottom plate 5 are arranged side by side along the horizontal direction, the middle part of the lower surface of the front top plate 4 is integrally connected with the top of the front rib plate 7, The plate surface of the front rib plate 7 is located in the left-right direction, the bottom of the front rib plate 7 is integrally connected with the middle part of the upper surface of the front base plate 5, and the front end side of the front base plate 5 is connected with the rear end side of the front lower arc-shaped bent plate 6. The sides are integrally connected, the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com