Steering knuckle and bushing push-free process

A steering knuckle and bushing technology, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the smooth assembly of the bushing and difficult to assemble the king pin, so as to improve the service life, ensure the coaxiality, reduce the The effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0038] see Figure 1-5, the steering knuckle liner of the present invention is free from pushing technology, comprises the steps:

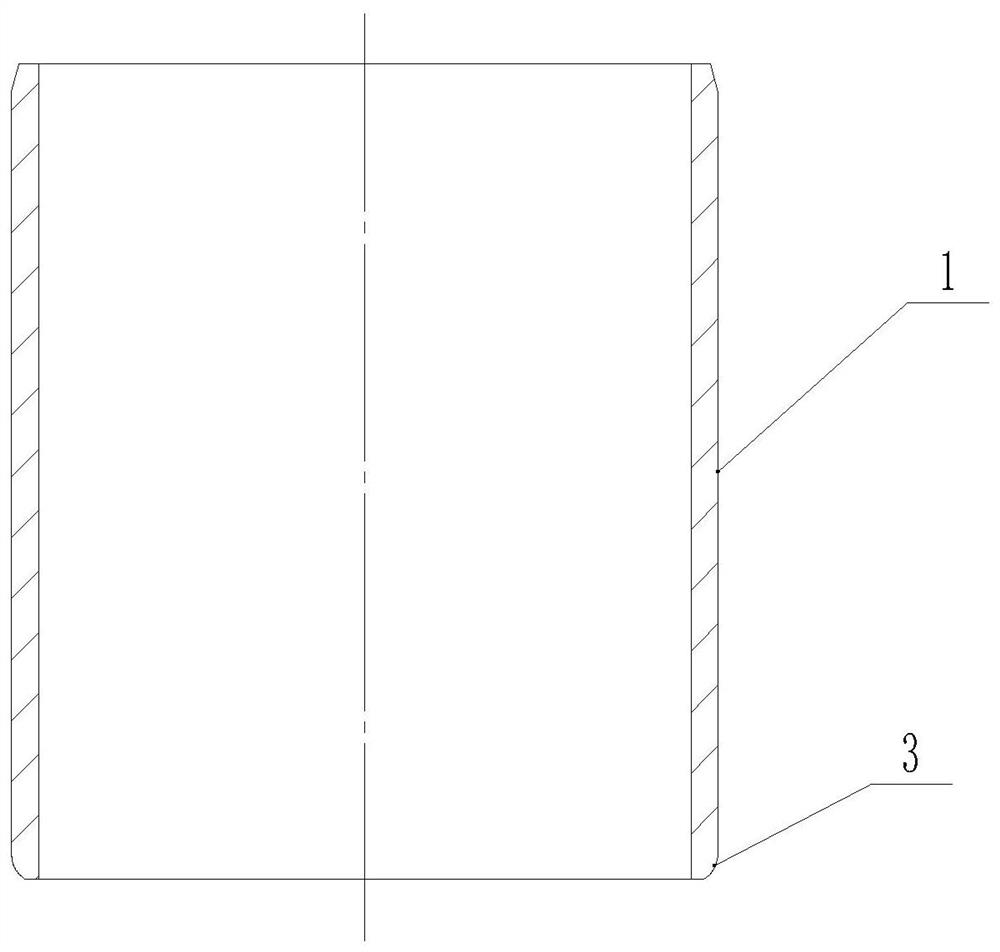

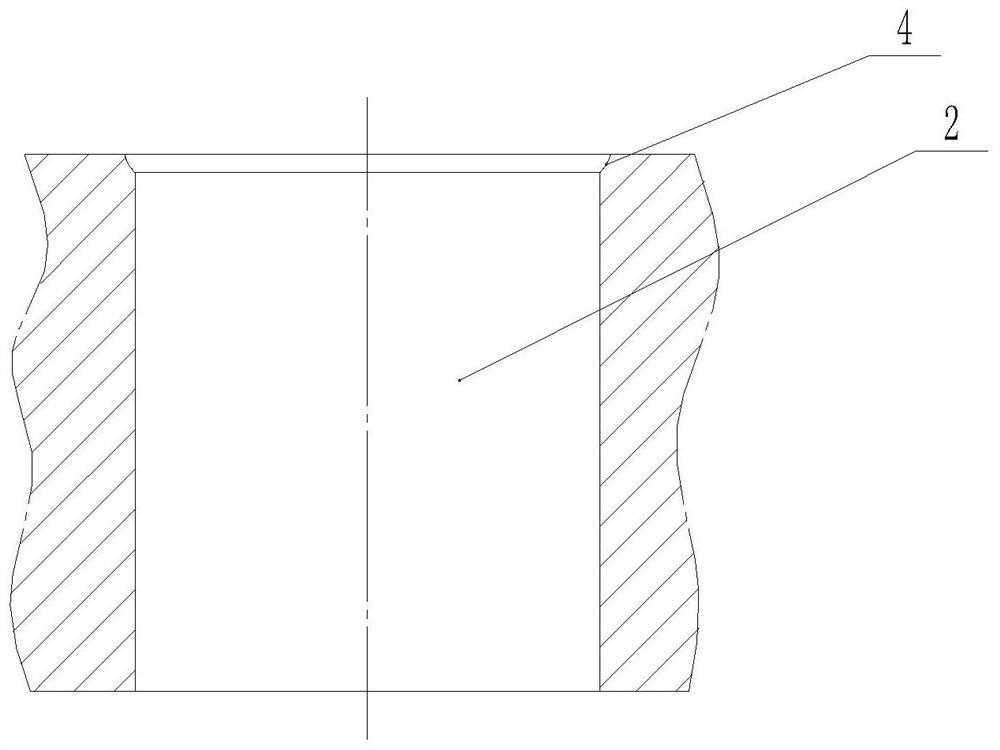

[0039] Step S1: Machining the outer circular guide angle 3 of the bushing: placing the bushing 1 in a CNC lathe, turning the outer circular guide angle 3 at the bottom of the bushing 1;

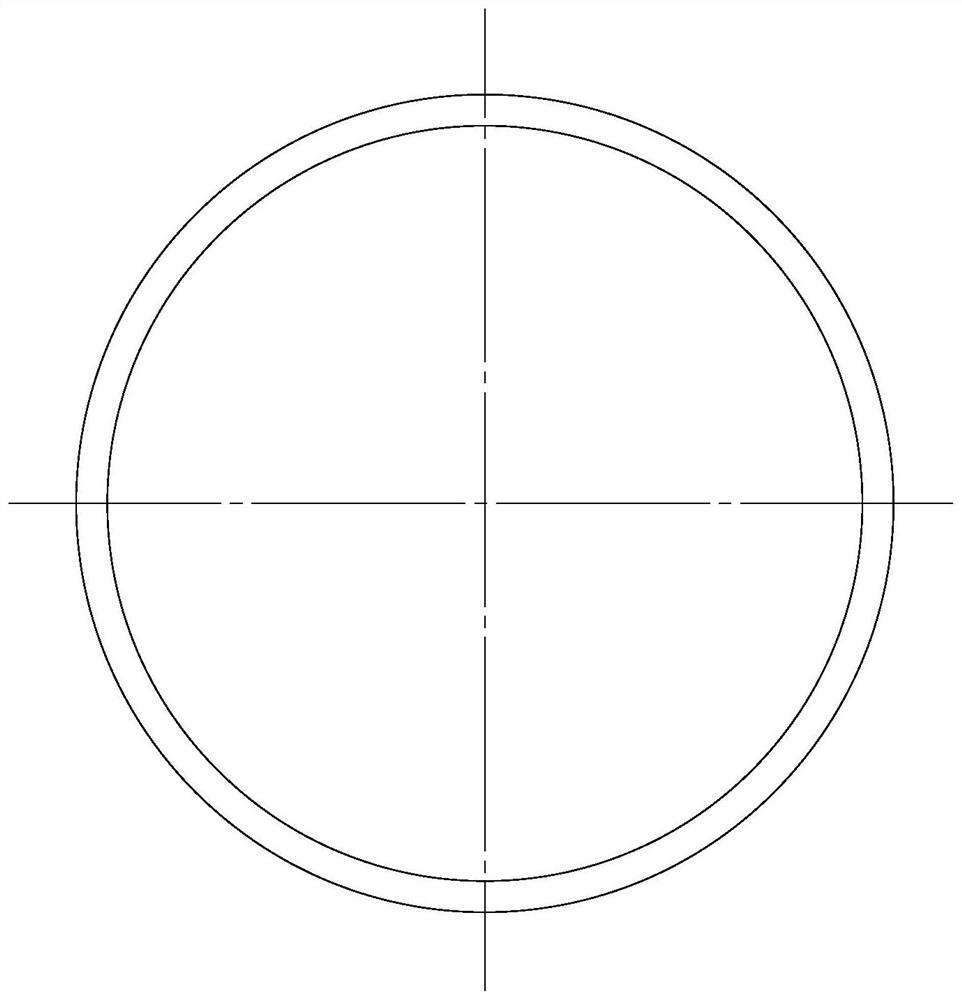

[0040] Step S2: Finishing of the steering knuckle kingpin hole: Fix the steering knuckle in the vertical machining center, and use the finishing process to bore the kingpin holes 2 of the upper and lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com