Method for preparing SON type metal oxide semiconductor field effect pipe device

A technology of oxide semiconductors and field effect transistors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the inability to truly apply VLSI manufacturing processes, high price and cost, and reduced production efficiency. Facilitate industrial production of large-scale integrated circuits, reduce production costs, and achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention are described in detail below.

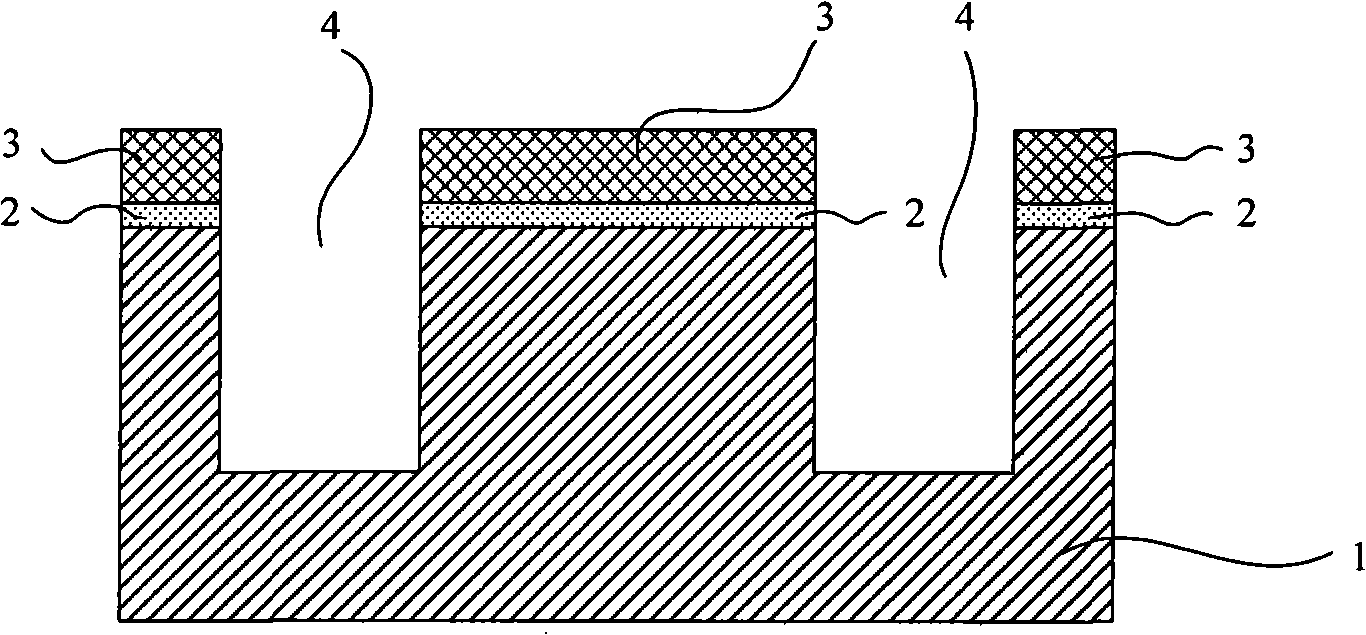

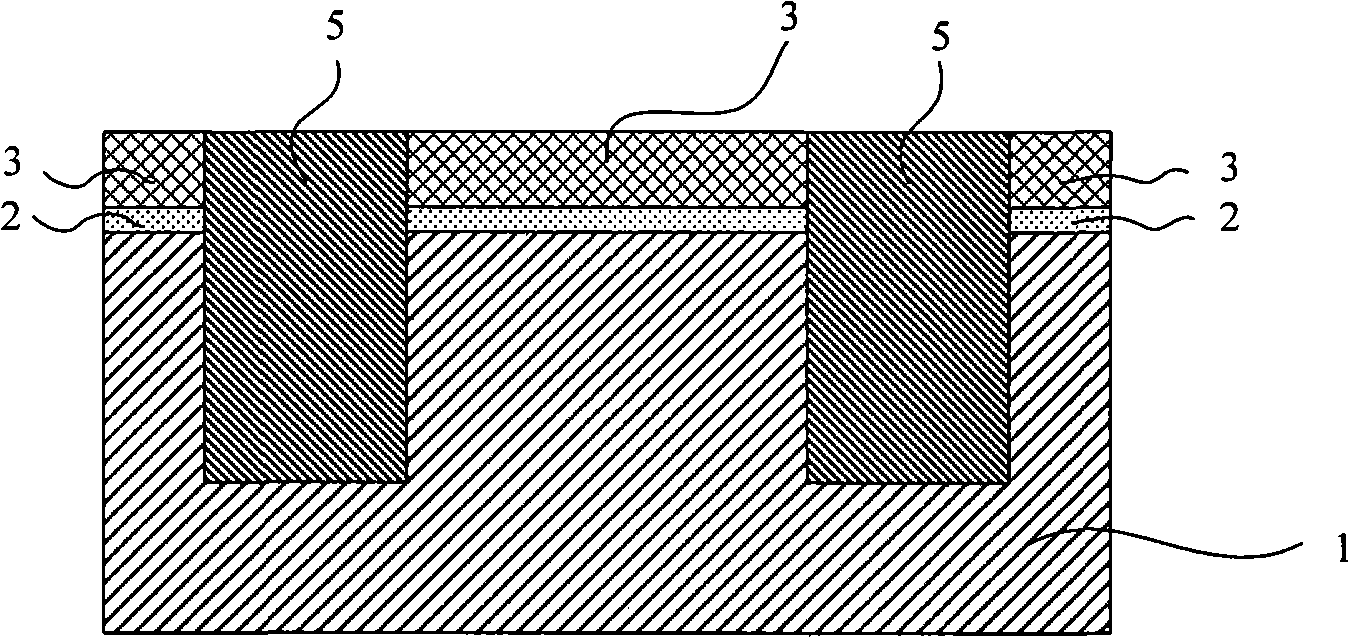

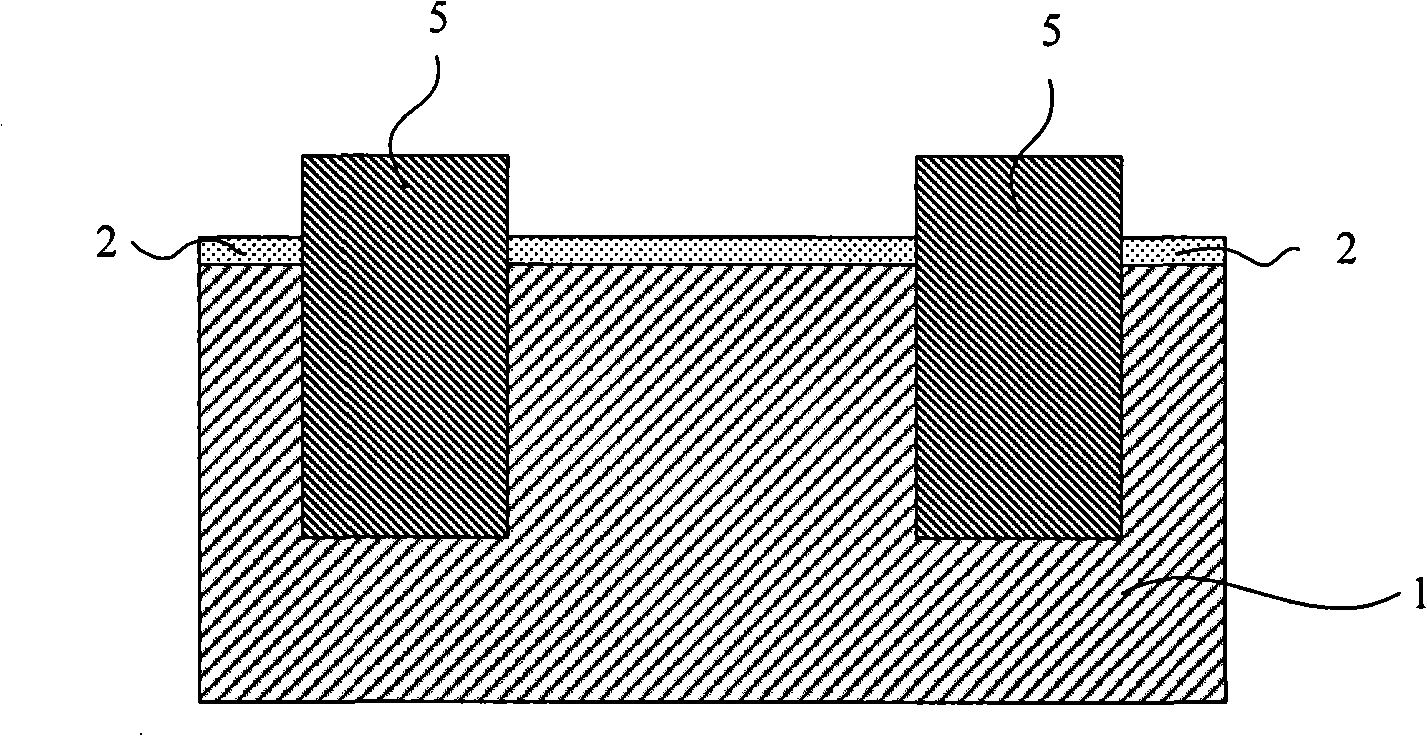

[0037] In the preparation method of the SON (Silicon-On-Nothing) type metal-oxide-semiconductor field effect transistor (MOSFET) device of the present invention, high insulation is obtained due to the technology of using low-cost neon ions implanted twice with different energies to form holes. The hollow layer with high performance has heat dissipation channels in the silicon substrate, thereby improving the defects of the SON device structure. At the same time, it is fully compatible with the conventional CMOS process, the process is simple, it is convenient for large-scale integrated circuit industrial production, and the production cost is reduced.

[0038] In the preparation method of the SON type metal oxide semiconductor field effect transistor device of the present invention, because the performance of forming the cavity layer in the gas ion implantation silicon chip depends on the bub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com