Method for improving service life of parts through ion chamber automatic cleaning through ion injection device

An ion implantation equipment and ion implantation technology are applied in the field of automatic cleaning of ion chambers of ion implantation equipment, which can solve the problems of rising maintenance costs and labor costs and occupying working time, so as to reduce maintenance costs and labor costs, increase working time, The effect of reducing maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] Principle of the present invention is as follows:

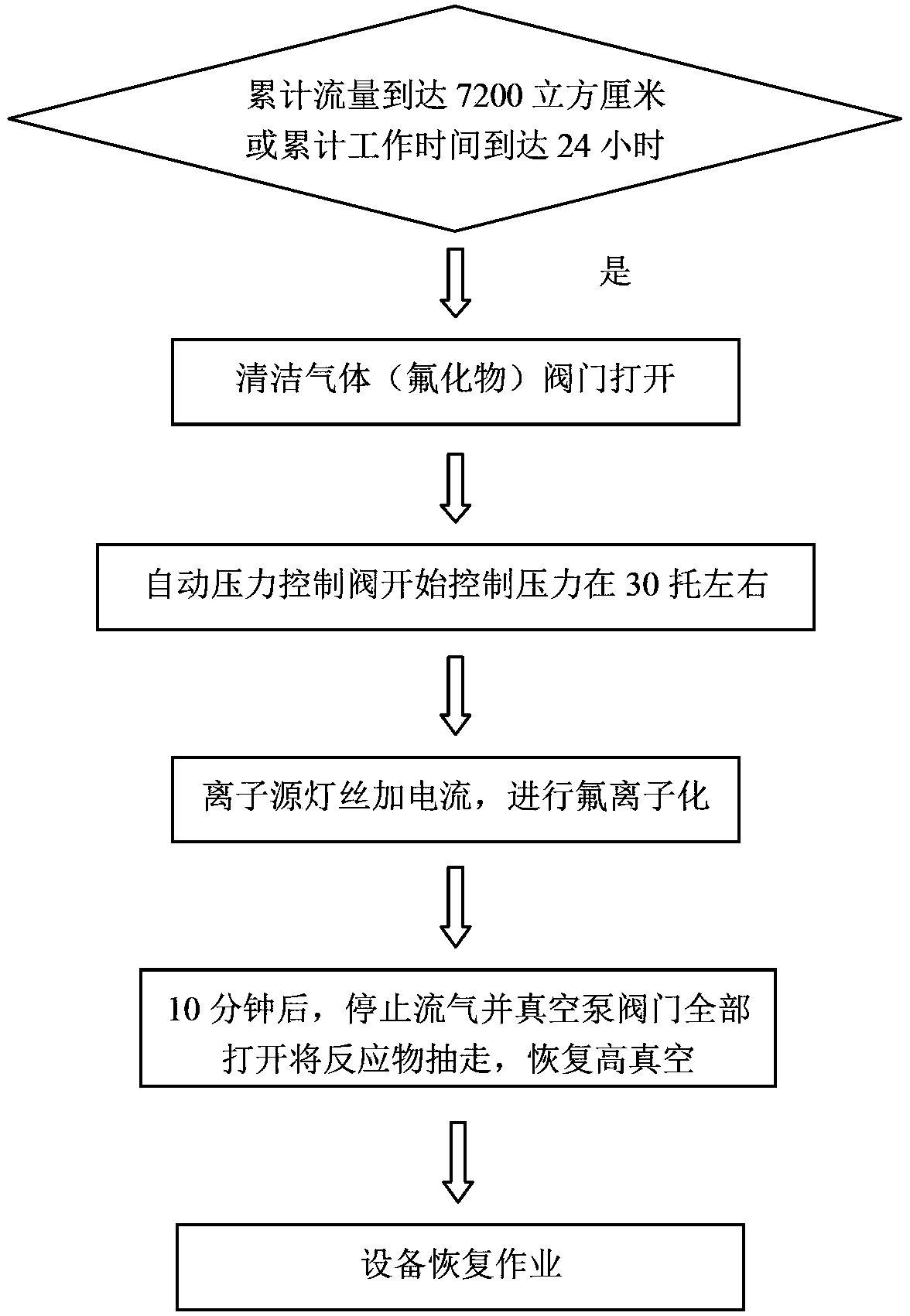

[0019] 1. Pass a large amount of fluoride gas (such as sulfur hexafluoride or dicarbon hexafluoride, which is stable, non-toxic and harmless) into the ion implantation chamber through the gas pipeline.

[0020] 2. The electrons emitted by the filament heating of the ion source are accelerated by the voltage and then bombard the fluoride gas to generate fluoride ions. Fluoride ions and doping residues (such as arsenic, phosphorus, boron, antimony, etc.) will undergo redox chemical reactions. The reaction products are arsenic trifluoride, phosphorus trifluoride, boron trifluoride and antimony pentafluoride.

[0021] 3. The reaction product is pumped away with a vacuum pump.

[0022] The reason why fluorine is chosen is because of its active chemical properties and strong oxidizing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com