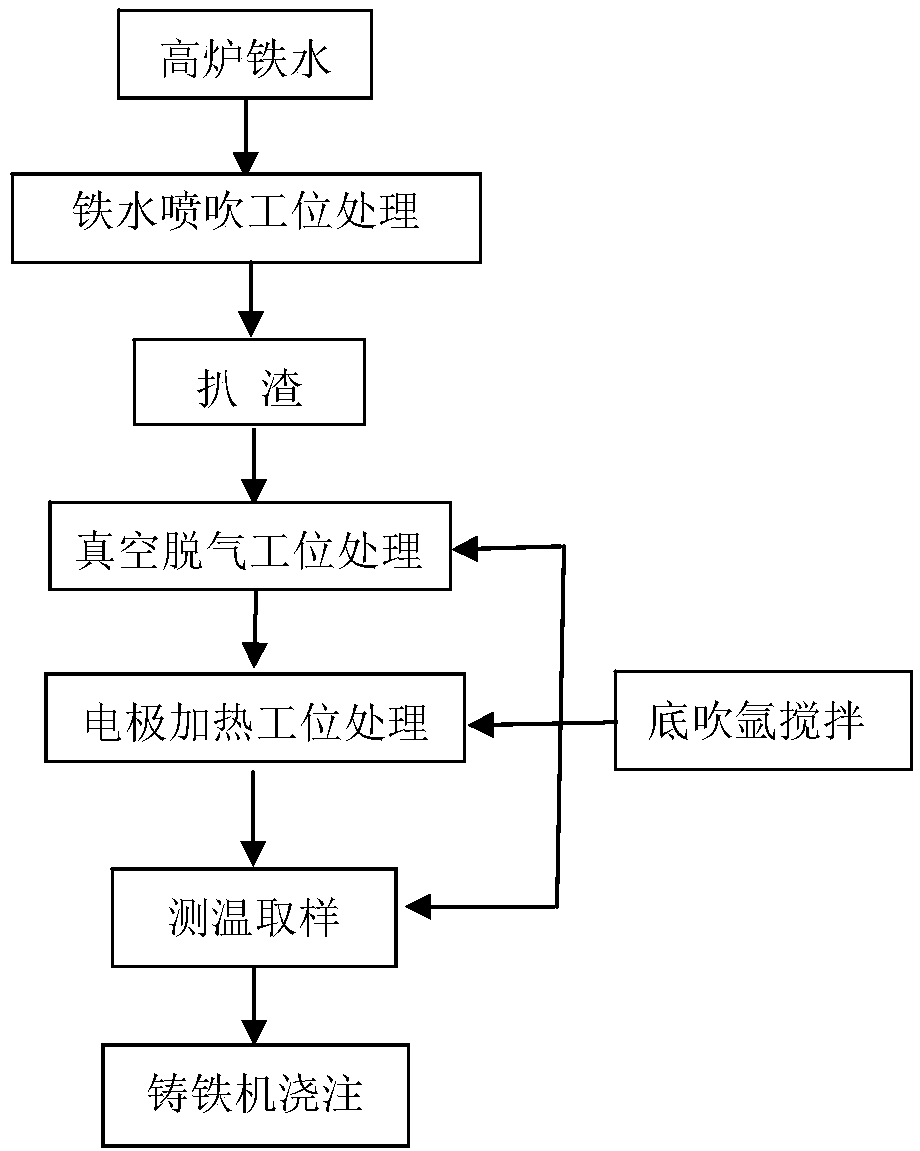

Process for producing high purity pig iron by molten iron injection, vacuum degassing and electrode heating

A vacuum degassing and high-purity pig iron technology, which is applied in the field of high-purity pig iron casting, can solve problems such as controlling the temperature of molten iron without specifying it, and achieve the effects of ensuring apparent quality, improving purity, and ensuring internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

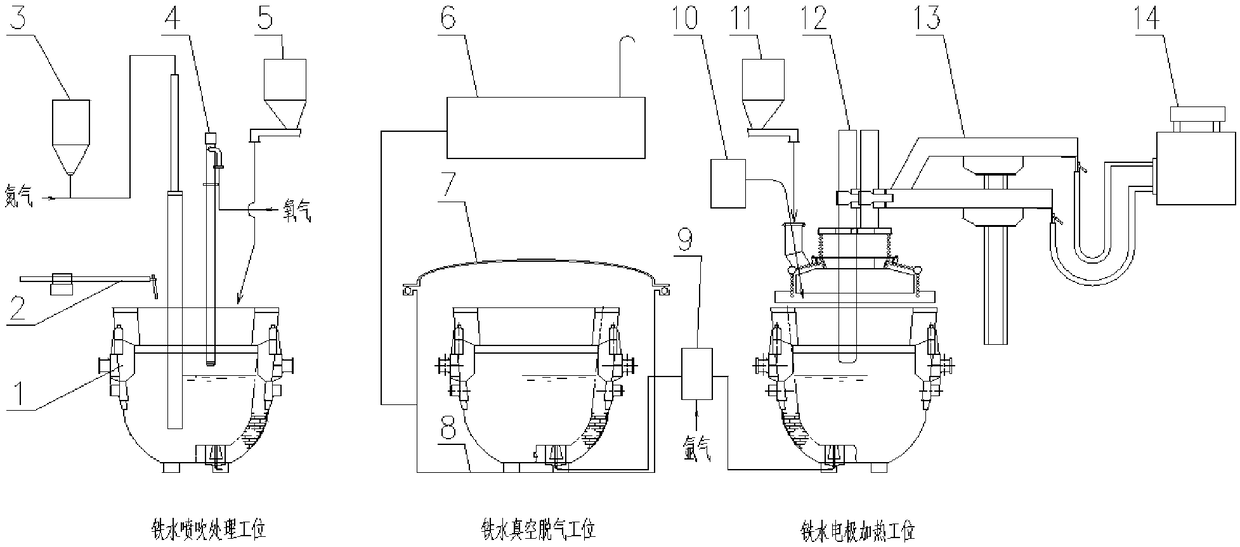

[0060] The smelting method for producing high-quality high-purity pig iron by using molten iron jet oxidation, vacuum degassing, and electrode heating will be introduced in detail below in conjunction with specific implementation examples.

[0061] (1) The composition (weight %) of molten iron sampling of ordinary blast furnace production is as follows:

[0062] C

Si

mn

P

S

Ti

margin

4.2

0.45

0.32

0.08

0.035

0.052

Fe

[0063] (2) Use the special ladle 1 with bottom blowing bricks to transport the weighed (40t) blast furnace molten iron to the molten iron injection treatment station, and the special ladle meets the clearance of 1300-1500mm when it holds 40t of molten iron;

[0064] (3) Use the slag removal machine 2 at the injection station to measure the temperature and take samples after removing the slag, and use the injection facility 3 to carry out the temperature measurement on the molten iron according to the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com