Insulation ladle automatic turning cover and dumping device

A pouring device and pouring ladle technology, applied in metal processing equipment, manufacturing tools, casting molten material containers, etc., can solve the problems of poor thermal insulation effect, good loss rate, complex opening and closing structure, etc., to prolong the casting time and prolong the cooling. time, guarantee the effect of pouring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

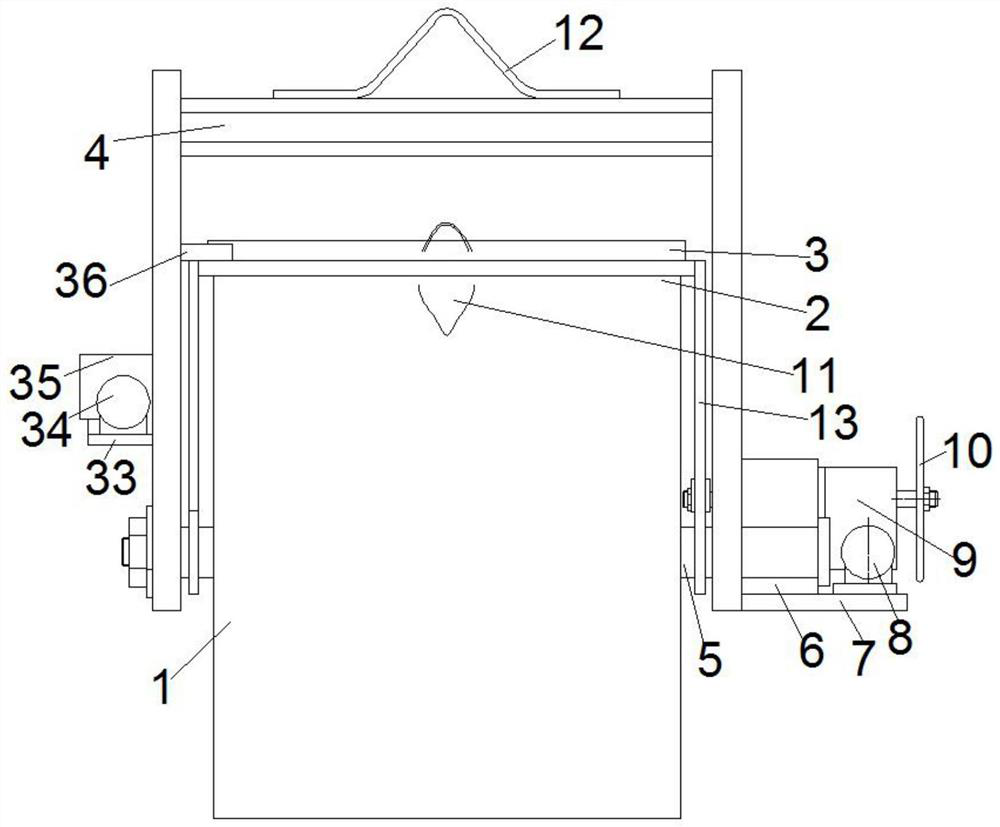

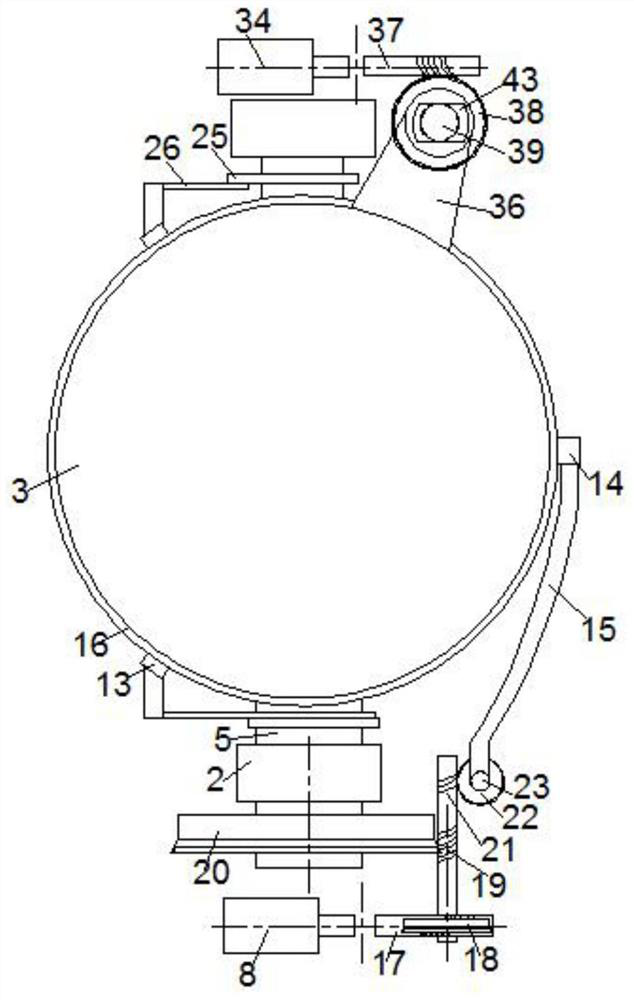

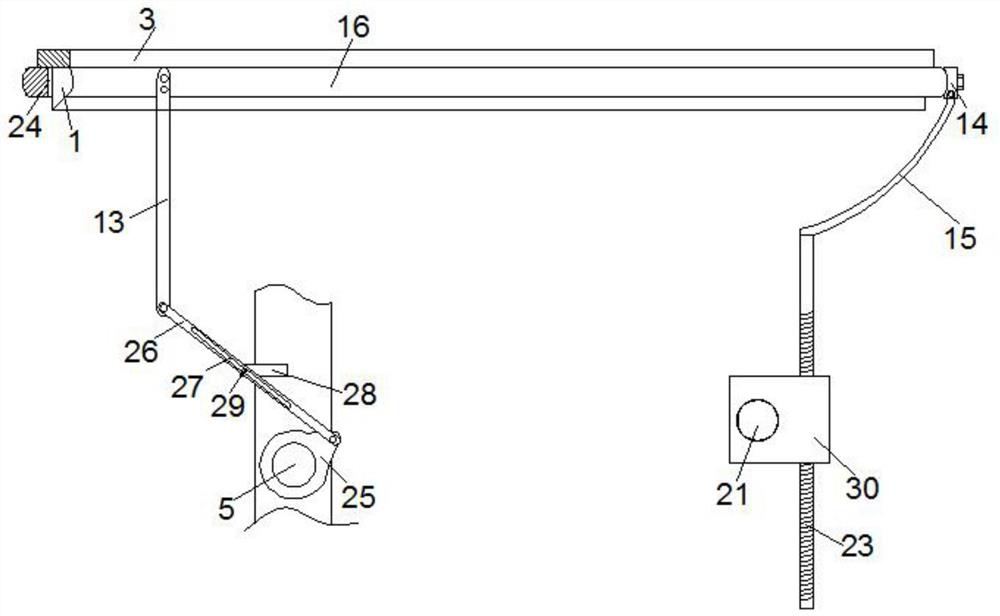

[0027] Such as Figure 1-6 Shown is a structural schematic diagram of the automatic cover turning and dumping device of the heat preservation ladle of the present invention; an automatic cover turning and dumping device of the heat preservation ladle of the present invention includes a ladle body 1 and a hanger 2, and the top of the ladle body 1 is movable A ladle cover 3 is installed, and the two sides of the ladle body 1 are symmetrically provided with an overturning shaft 5, and the overturning shaft 5 is movably hinged on the hanger 2, and the middle side wall of the ladle body 1 is provided with a discharge port 11. A ladle dumping device for connecting with the overturning shaft 5 is provided on the right side outer wall of the hanger 2, and the ladle dumping device includes a lateral reduction box 6 connected to the right side outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com