Method for smelting low-carbon alloy steel by utilizing RH decarburization

A low-carbon alloy steel and decarburization technology, applied in the manufacture of converters, etc., can solve the problems of loss of internal quality of steel, influence of molten steel purity, molten steel post-blowing, etc., to reduce serious post-blowing, meet chemical composition requirements, and ensure Effect of molten steel pouring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

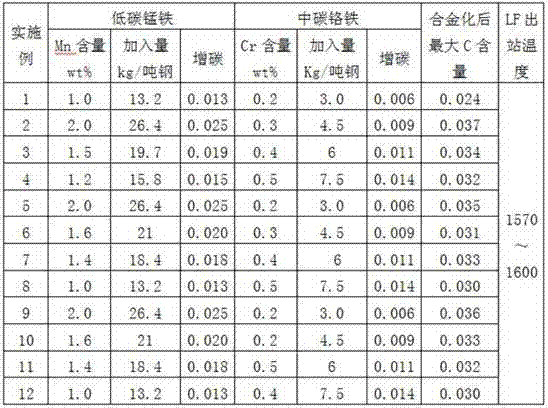

[0011] Embodiment 1-12: The method for smelting low-carbon alloy steel by using RH decarburization adopts the following process.

[0012] (1) This method changes the traditional steelmaking process and subverts the traditional mode of deoxidation alloying after converter smelting. Add RH treatment process in the process of smelting low carbon alloy steel, use RH to carry out deep decarburization of molten steel, then heat up in LF, and place deoxidation alloying in LF refining process; the process flow is converter-RH-LF —Continuous casting. RH can decarburize molten steel. The decarburization principle is to use oxygen in molten steel to decarburize under vacuum conditions to generate CO / CO. 2 Gas, discharged from molten steel. It will neither damage the quality of molten steel, but also reduce the carbon content in steel to a very low level. The tasks of each process are also fundamentally different from the traditional method, see Table 1 for specific comparison.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com