A compensation injection method for effectively reducing LDNMOS cut-off current and avoiding dual peak feature and its application

A technology of cut-off current and characteristics, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems affecting the low leakage performance of the device and the high power consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

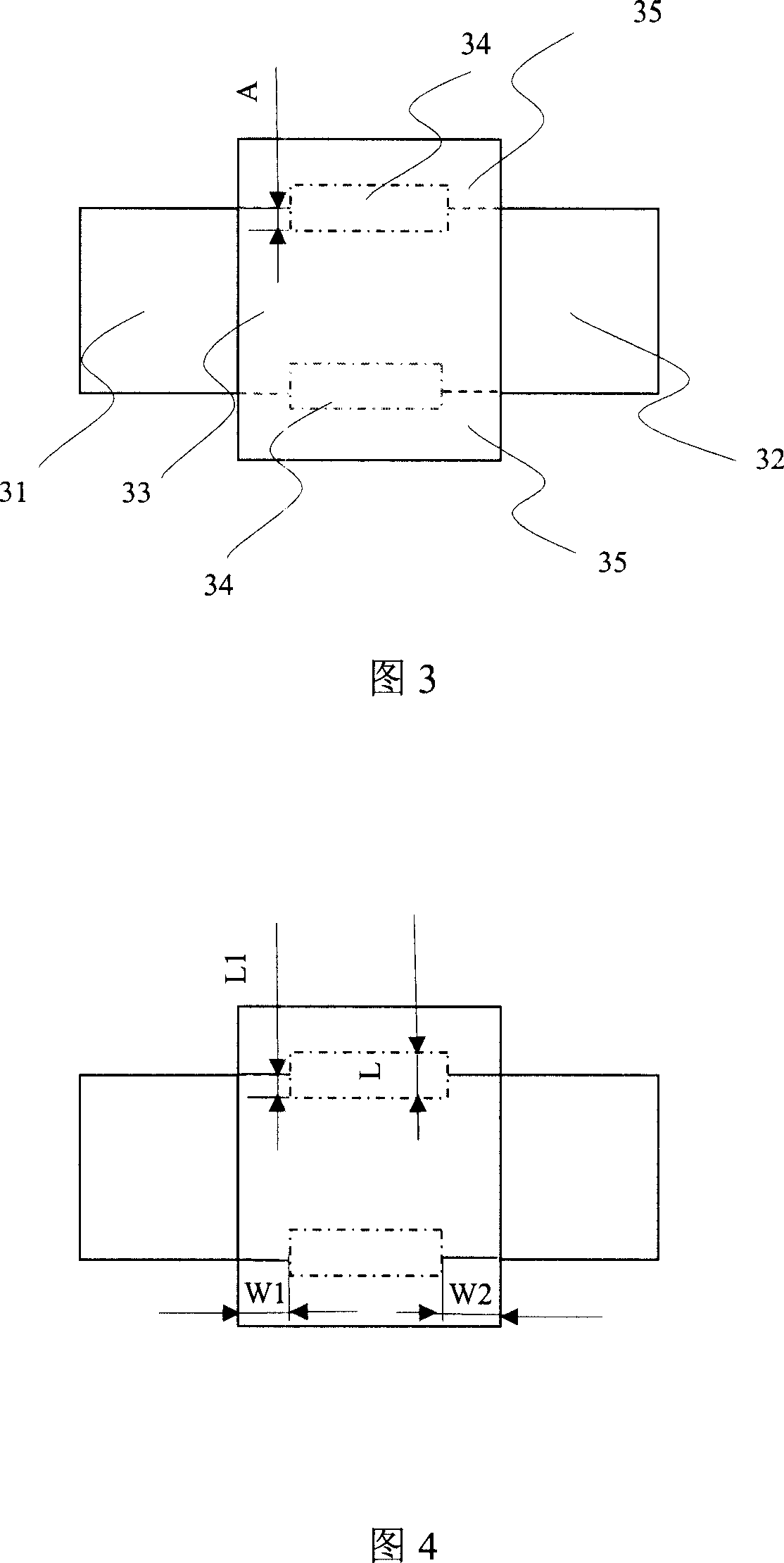

[0023] In the existing manufacturing flow of LDNMOS with channel length = 3.5um and channel width = 20um 40V, a photolithography is added after the existing triple gate (Triple Gate) process.

[0024] Specific areas are patterned on the mask used in this additional lithography.

[0025] Referring to Fig. 4, L1 in the figure is 0.2um, and L is 0.5um. W1=W2=0.5um.

[0026] After exposure and baking, B ion implantation is performed.

[0027] B ion implantation, using 20kev-50kev, B doping concentration using 10 12 -10 13 / cm 2 .

[0028] After the ion implantation, the photoresist is removed, and the subsequent LDNMOS production process is performed, and these subsequent processes are the same as the prior art.

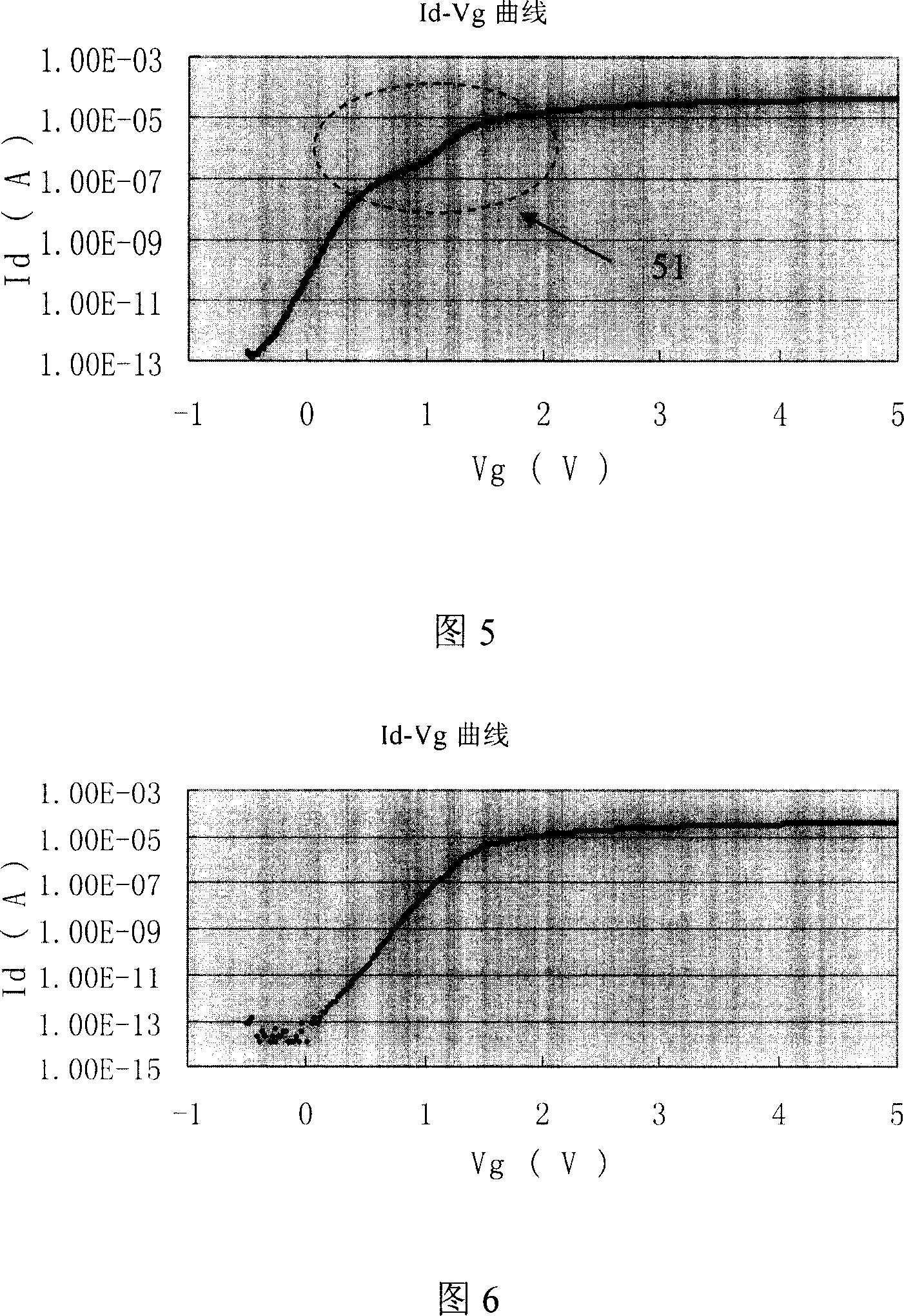

[0029] The LDNMOS transistor produced after using the embodiment is detected, and its Id-Vg characteristic curve is shown in Figure 6. When Vg=0V, Id is about 1.00E-13A / um; and in the existing transistor Id-Vg curve , the Id value when Vg=0V is about 1.00E-11A / um....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com