Method for three-box casting of large movable beam and movable column planer type milling machine lathe bed

A technology of gantry milling machine and milling machine, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of slow production efficiency of milling machines, and achieve the effect of improving production efficiency and avoiding dislocation phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

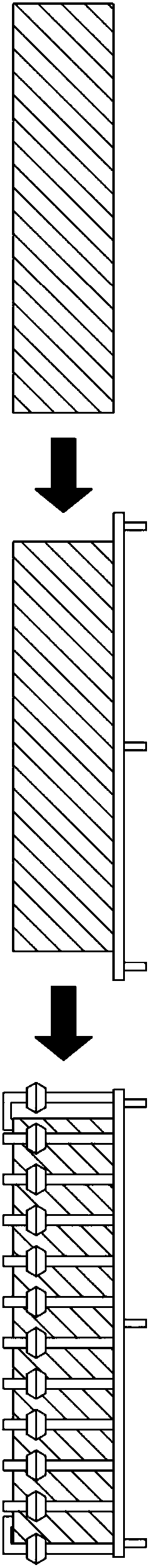

[0027] The present invention provides such figure 1 A three-box casting method for the bed of a large-scale moving beam moving column gantry milling machine includes the following manufacturing methods:

[0028] Step 1: Milling machine design: According to the structural characteristics, technical requirements and production model of the casting, determine the casting plan and manufacture the corresponding milling machine mold design drawing;

[0029] Step 2: Milling machine mold production: According to the milling machine mold drawing designed in step 1, the milling machine mold is produced, and the injection pipe is fixed around the top of the milling machine mold, and the injection pipe is set on the top of the injection pipe. input connection;

[0030] Step 3: Laying of multi-point split-flow straight-in pipes: After step 2 is completed, according to the design drawing of the milling machine mold designed in step 1, lay split-flow straight-in pipes around the milling mac...

Embodiment 2

[0035] The difference with embodiment 1 is:

[0036] In step 1, the milling machine mold design drawing is drawn by the computer and stored in the computer, which is beneficial to avoid data loss and provide data comparison for later detection and maintenance;

[0037] In step 2, there are 4 groups of plastic injection pipes, of which 1 group is provided at the top of both ends of the injection molding pipe and 1 group is respectively provided at the top of the middle and both sides of the injection molding pipe. ;

[0038] In step 4, when the molten steel is injected, 4 sets of plastic tubes are injected simultaneously, and when the injection is performed, the vibrator is used to vibrate the molten steel in the mold of the milling machine at the same time, so as to avoid the formation of bubbles when the molten steel is injected, and the bubbles When the molten steel is solidified, hollowing will occur inside the milling machine, which will affect the quality of the milling ...

Embodiment 3

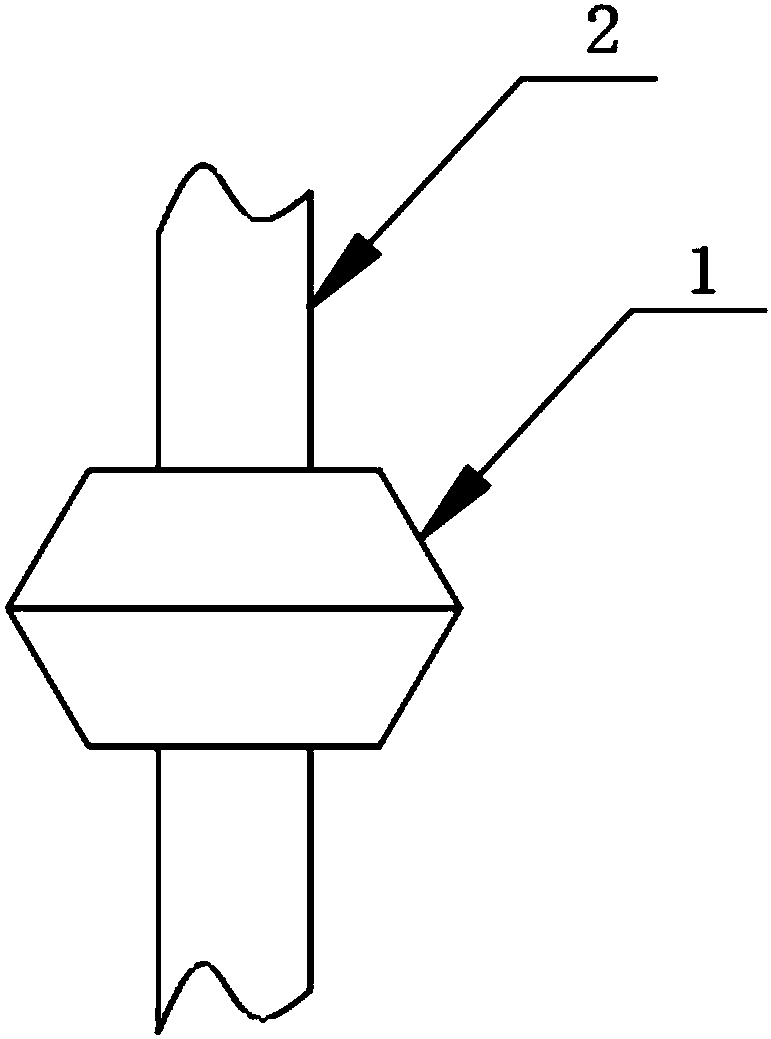

[0042] The present invention provides such figure 2 The shown is a fixed sleeve for preventing misalignment of the direct-flow pipeline, which includes a fixed sleeve 1 and a main body 2 of the direct-flow pipeline. The fixed sleeve 1 includes an upper butt joint surface cavity and a lower joint surface cavity. It includes an upper diversion straight-in pipeline and a diversion straight-in pipeline, the upper diversion straight-in pipeline and the lower diversion straight-in pipeline are integrally arranged, the top of the upper butt joint surface cavity is fixedly connected to the bottom of the upper diversion direct inflow pipeline, and the lower butt joint surface cavity The bottom is fixedly connected with the top of the direct inlet pipe of the lower diversion;

[0043] The shape of the upper branch direct-inflow pipe and the lower branch direct-inlet pipe is set as a circular platform, and the inside of the fixed sleeve 1 is set as a hollow structure.

[0044] Benefici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com