Molten iron spraying desulfurization spraying gun

A desulfurization spray gun, molten iron technology, applied in the direction of manufacturing converters, etc., can solve the problems of the gun core can not be reused, the main pipe is twisted and deformed, and cannot be extracted and replaced, so as to facilitate the extraction and replacement, enhance the riveting force, and improve the repair. The effect of the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

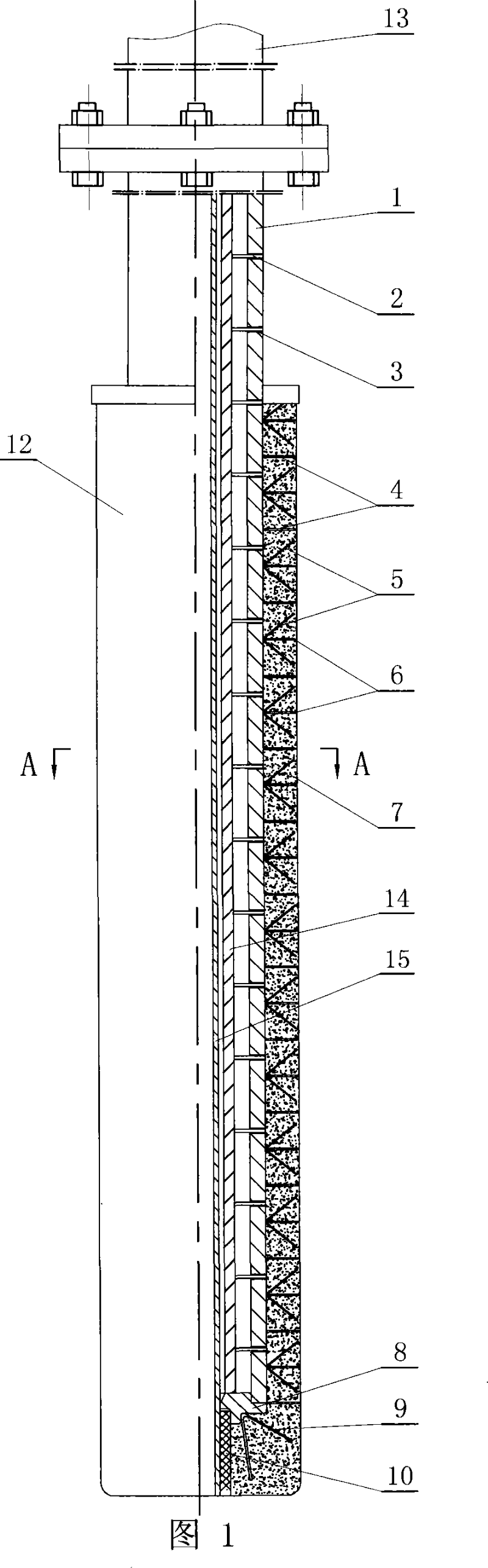

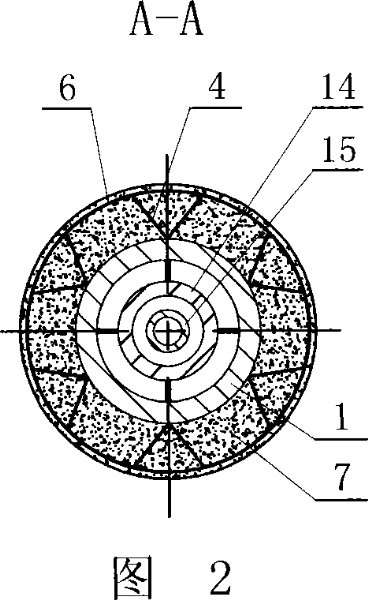

[0016] Specific embodiment one: referring to Fig. 1 and Fig. 2, the molten iron injection desulfurization spray gun described in this embodiment is composed of a gun shaft 13 and a spray gun complex 12 connected to the flange of the gun shaft 13, and the spray gun complex 12 includes a reinforcing tube 1, a set The main pipe 14 in the reinforcing pipe 1 and the blowing pipe 15 arranged in the main pipe 14, the graphite blowing pipe mounting seat 8 is fixed under the strengthening pipe 1 and the main pipe 14, and the graphite blowing pipe is arranged on the outside of the blowing pipe 15 bottom 10, and the graphite blowing pipe 10 is fixed on the graphite blowing pipe mounting seat 8, the outer side of the reinforcing pipe 1 is provided with a refractory gun lining 7, and the reinforcing pipe 1 and the main pipe 14 are uniformly arranged radially and axially. A bypass weldment 2 is fixed; a bridge weldment mounting hole 3 is opened on the reinforcing tube 1, and the bridge weldm...

specific Embodiment approach 2

[0022] Specific embodiment two: Referring to Fig. 1 and Fig. 2, the structure and manufacturing method of this embodiment are the same as those of the molten iron injection desulfurization lance described in specific embodiment one, the difference lies in the selection of materials, specifically as follows: adopt No. 15 The carbon steel seamless pipe is used to make the blowing pipe 15, the main pipe 14, and the reinforcing pipe 1. The graphite blowing pipe mounting seat 8 is made of No. 35 steel. The diameter is 3mm smaller than the outer diameter of the refractory gun lining, and the wire rod with a wire diameter of 10mm is used to make the V-shaped rivet 4, the double-V butterfly rivet 5 and the gun head V-shaped rivet 9. The bridging weldment 2 is made by shearing threaded steel wire rod with a wire diameter of 10 mm, and the graphite blowing pipe 10 is made by using waste graphite electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com