Three-color plastic sole molding machine

A molding machine and plastic technology, used in household components, household appliances, other household appliances, etc., can solve problems such as low thermal efficiency, and achieve the effects of high heating efficiency, reduction of operators, and rapid temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

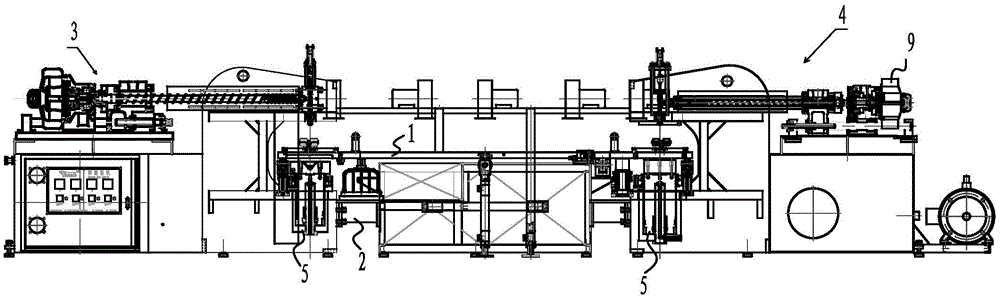

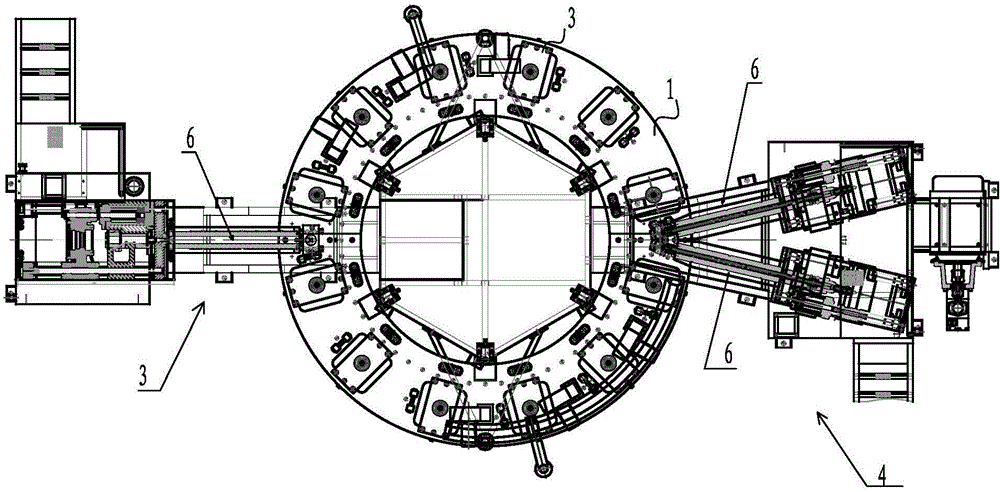

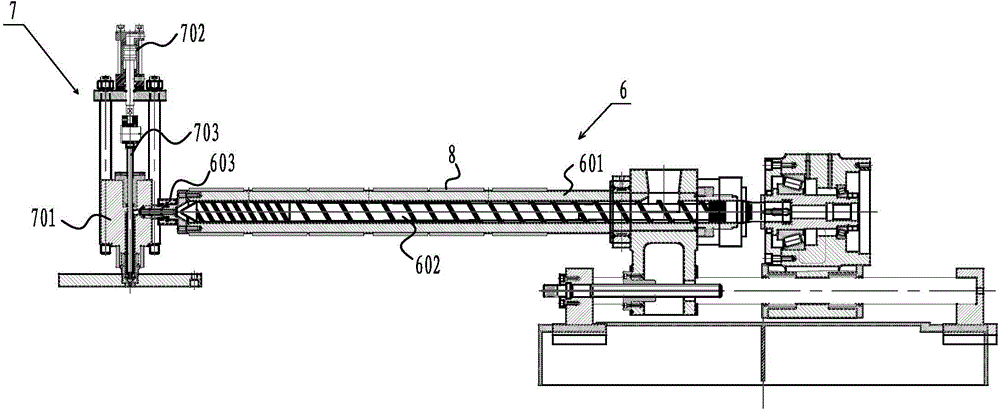

[0011] Such as figure 1 , 2 As shown, the three-color plastic sole molding machine includes a clamping mechanism 5, a turntable mechanism, a main injection device 3 and a secondary injection device 4, a hydraulic system and a control system. The turntable mechanism includes a circular rotary table 1 and its driving mechanism 2. The rotary table 1 is evenly provided with a plurality of shoe mold stations 3 along the circumference. In this specific embodiment, 12 shoe mold stations 3 are arranged in total. The main injection device 3 is provided with a set of plasticizing and injection mechanisms 6 , and the auxiliary injection device 4 is provided with two sets of plasticizing and injection mechanisms 6 . Such as image 3 As shown, the plasticizing and injection mechanism 6 is provided with a barrel 601, and the barrel 601 is provided with a heating device 8, and the barrel 601 is provided with an injection screw 602, and the injection screw 602 is made of iron material, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com