Method for shrinking line-shaped pattern character size

A technology of pattern features and feature size, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as cost increase, etching deviation difference, inability to ensure device feature size uniformity, etc., to ensure uniformity, reduce effect of difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

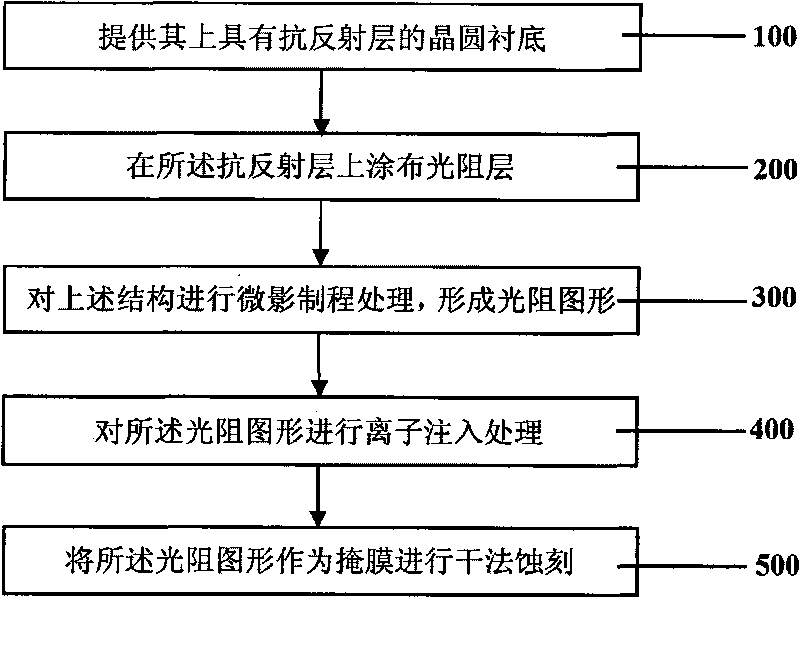

[0029] In order to better understand the technical content of the present invention, specific embodiments are described in conjunction with the accompanying drawings as follows.

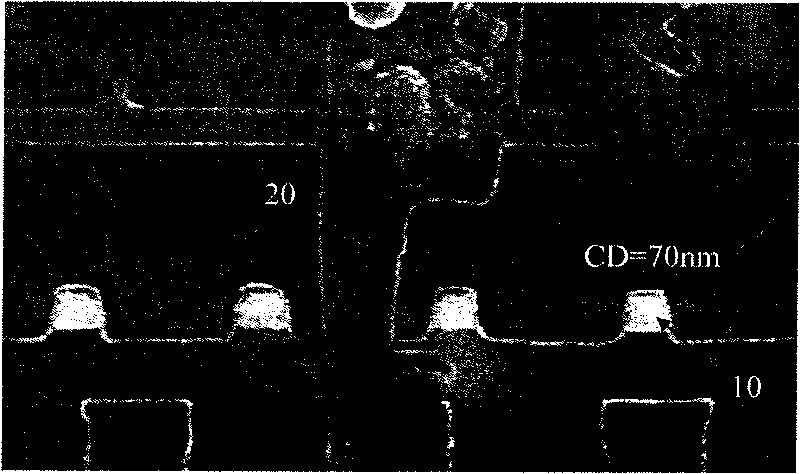

[0030] The present invention provides a method for shrinking the feature size of a linear pattern, which can effectively shrink the feature size of the photoresist, ensure the uniformity of the feature size of the device on the entire wafer, and make the roughness of the linear edge of the photoresist smoother .

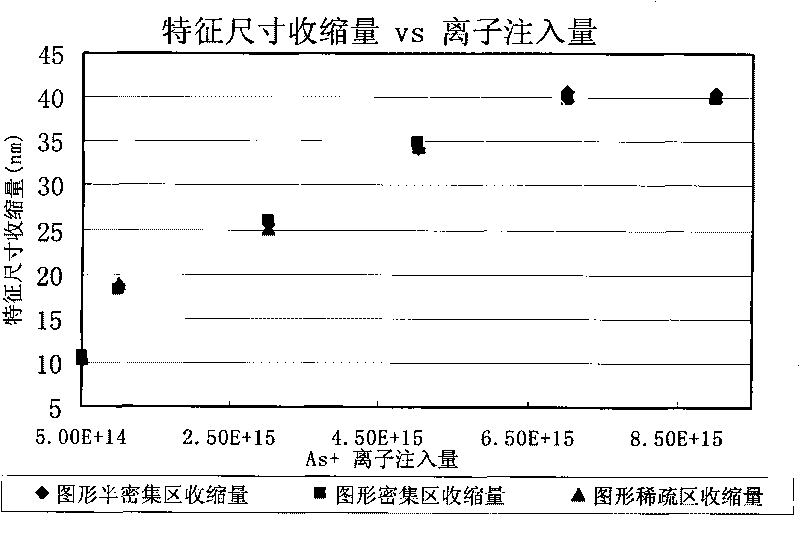

[0031] The method for shrinking the feature size of the linear pattern includes: performing ion implantation on the photoresist pattern as a mask to shrink the feature size of the photoresist pattern.

[0032] Through ion implantation of the photoresist pattern as a mask, not only the feature size of the photoresist pattern can be reduced, but also the etching resistance of the photoresist pattern in the subsequent etching process can be increased. Therefore, the photoresist In the process where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com