Turnover type balling ladle cover

A flipping and covering technology, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive overall movement, inconvenient operation, cumbersome separation and installation, etc., to reduce splashing, increase injection speed, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

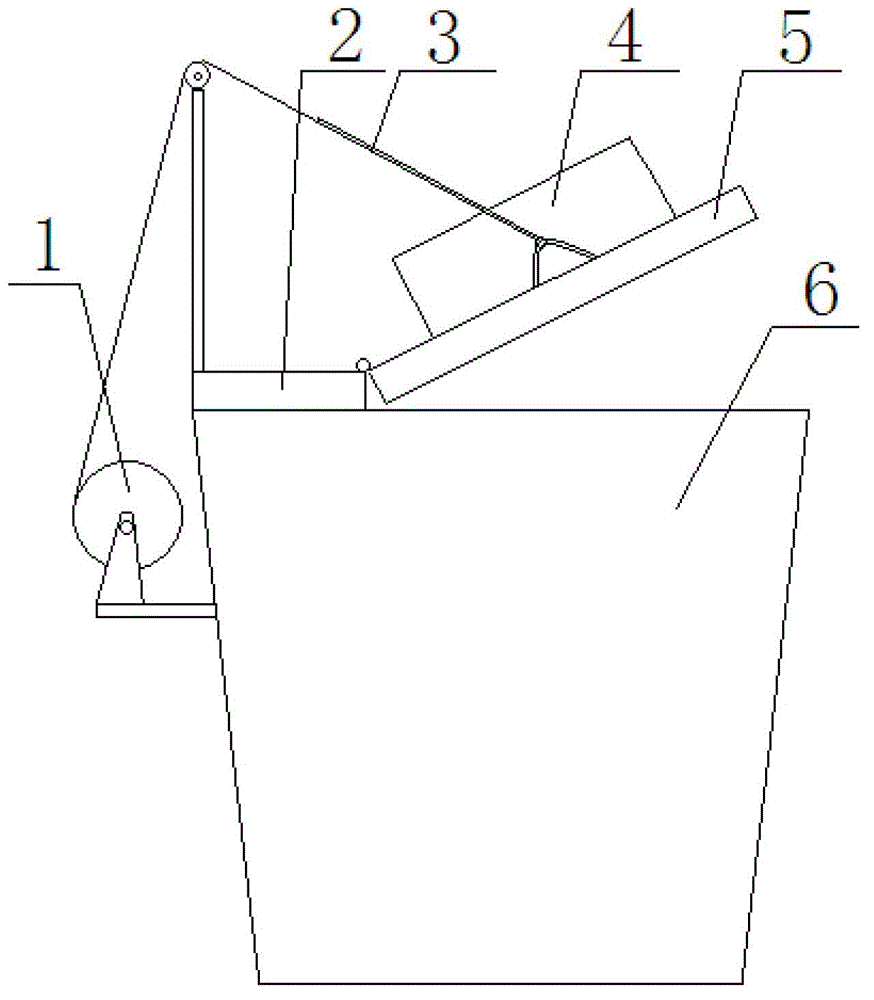

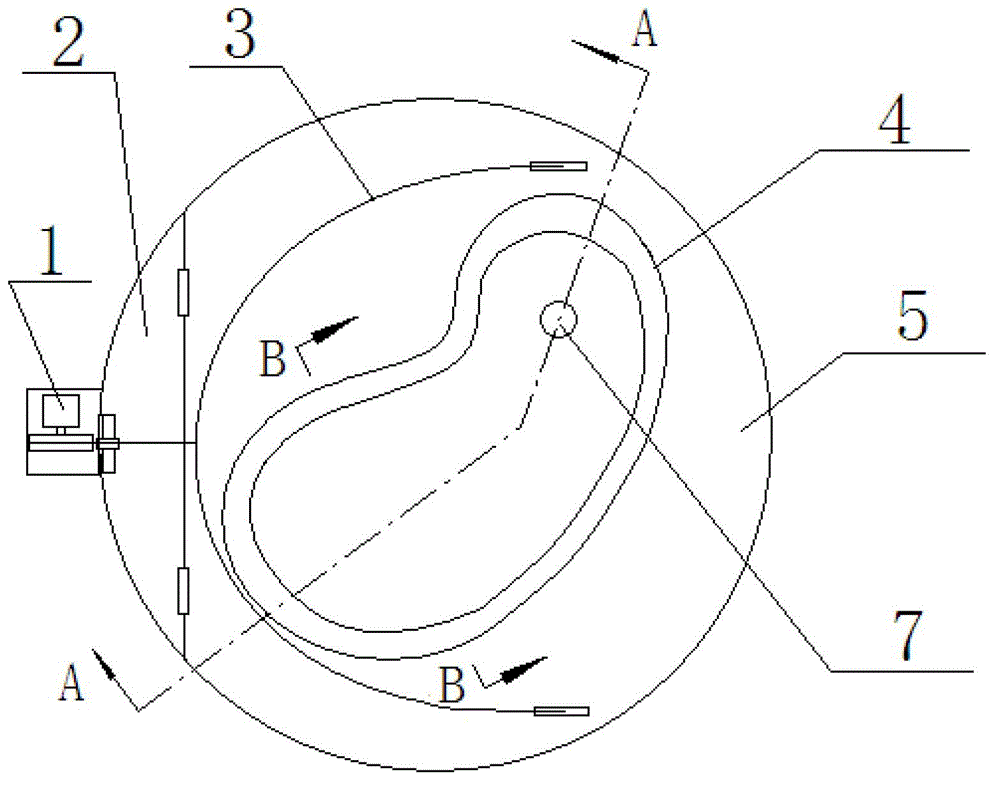

[0013] Such as figure 1 with figure 2 As shown, the flip-type spheroidized bag cover includes a bag body and a flip-type bag cover. The flip-type bag cover is composed of a fixed cover 2 and a movable cover 5. It is characterized in that the movable cover 5 is hinged to the fixed cover 2 , a handle 3 is set on the edge of the movable cover, and the handle is connected with the hoist 1 arranged on the outer wall of the bag body 6 through a rope; the drainage device 4 is arranged on the movable cover 5; wherein:

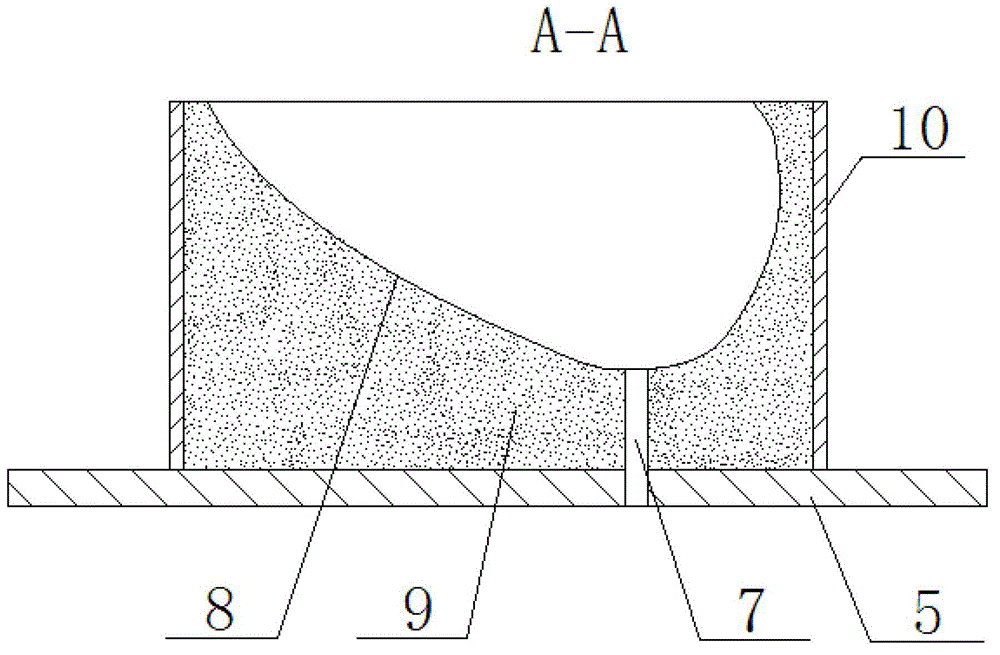

[0014] Such as image 3 with Figure 4 As shown, the drainage device 4 includes a casing 10 and a drainage device body 9 made of a hard refractory material; the drainage device body 9 has an arc-shaped groove, and its center section structure along the arc direction has a ramp 8. Both ends of the arc-shaped groove are arc-shaped, and the transverse section of the drainage device 4 is a parabola, arc or ellipse with an upward opening; the molten iron injection port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com