High-end casting following nucleating agent injection device

An injection device and flow inoculation technology, which is applied to casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of uneven inoculant injection and affecting the quality of castings, and achieve good inoculation effect, easy disassembly and assembly, and strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

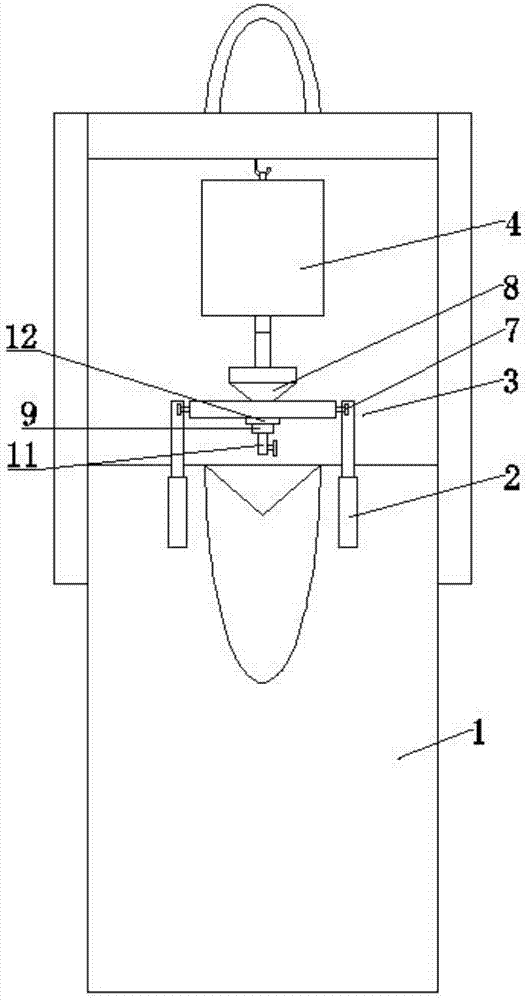

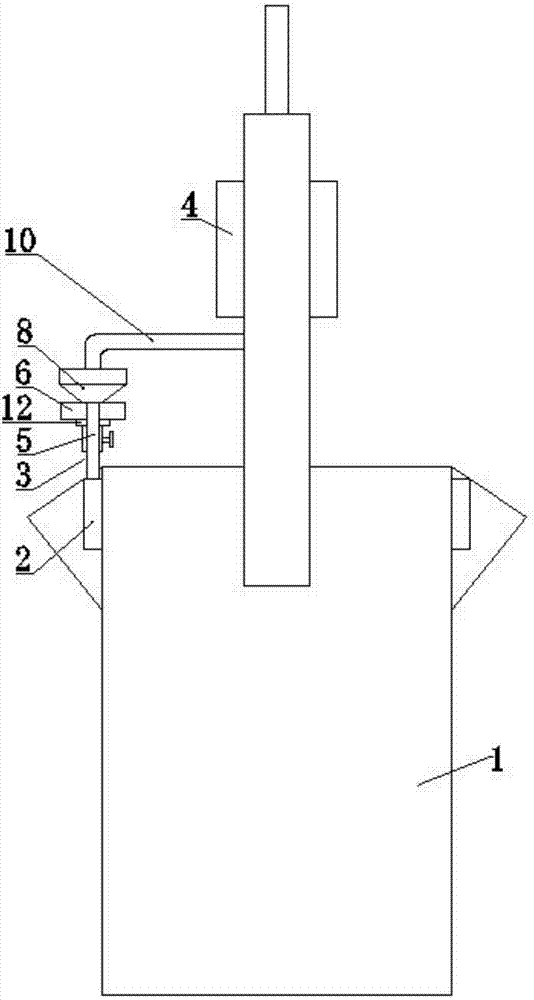

[0024] A high-end casting inoculant injection device in this embodiment includes a ladle 1, fixed sleeves 2 are arranged on both sides of the molten iron filling nozzle of the ladle 1, and an inoculant injection device is installed above the fixed sleeve 2, and the inoculant injection The device includes an insertion bracket 3 and an inoculant storage tank 4; the insertion bracket 3 includes an insertion rod 5 and a horizontal plate 6, and the insertion rod 5 is inserted in the fixed sleeve 2; body 7; the upper end of the relative inner surface of the insertion rod 5 is provided with a rotating groove that matches the cylindrical fixed body 7, and a bearing is provided at the joint between the connecting shaft and the insertion rod 5; a mounting hole is provided at the center of the horizontal plate 6, and a filling funnel is provided in the mounting hole 8. The discharge pipe 9 at the lower end of the injection funnel 8 passes through the installation hole; the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com