Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

A production method and high-toughness technology, applied in low-temperature-resistant high-toughness cast ductile iron, production and application fields, can solve problems such as poor desulfurization effect, poor nodularization, large dosage of nodulizers and desulfurizers, and achieve The effect of prolonging the effective time of incubation, facilitating absorption, and delaying the onset time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

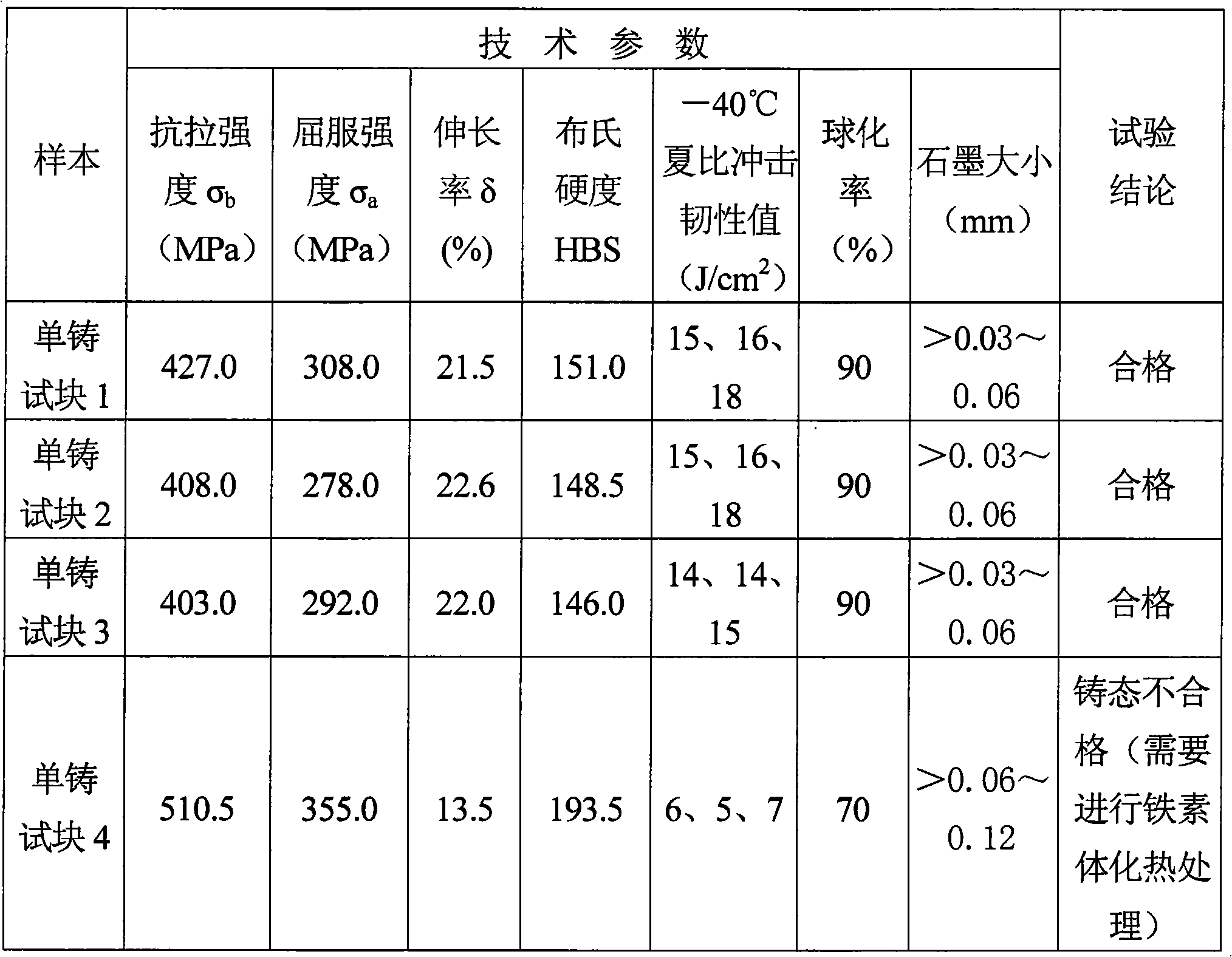

Examples

Embodiment 1

[0044] A low-temperature-resistant high-toughness cast ductile iron, the chemical composition of which is: C=3.6%, Si=2.06%, Mn=0.18%, P=0.02%, S=0.01%, Mg 残留 =0.048%, ∑Re 残留 =0.021%, Sr=0.08%, Ni=0.23%, Ti=0.13%, and the balance is Fe.

[0045] The production method of the low-temperature-resistant high-toughness cast ductile iron comprises the following steps:

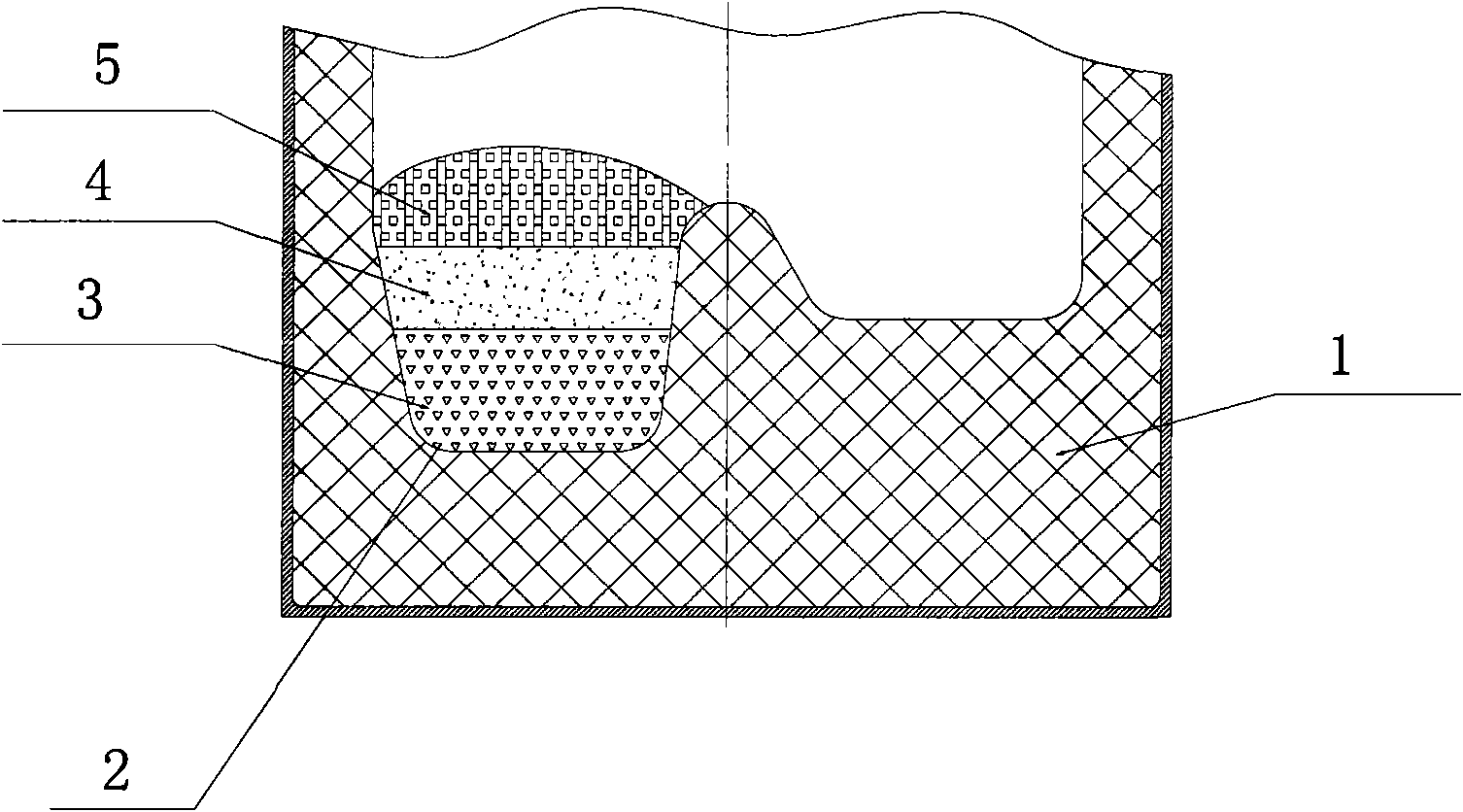

[0046] (1) Prepare the ladle and repair the bottom hole

[0047] Select a molten iron ladle with a capacity of 0.5 tons, and repair the refractory layer according to the conventional process regulations (clay refractory bricks are used to lay the wall of the molten iron ladle, and a layer of refractory dressing is applied on it, and the refractory dressing is 10-15% refractory clay, 20-25% red Coal powder, the balance is 40 / 70 mesh quartz sand, add appropriate amount of water and mix to form agglomerates), in the middle of the bottom, use clay refractory bricks and refractory dressings to repair and enamell Φ300×35...

Embodiment 2

[0064] A low-temperature-resistant high-toughness cast ductile iron, the chemical composition of which is: C=3.6%, Si=2.08%, Mn=0.16%, P=0.019%, S=0.008%, Mg 残留 0.048%, ∑Re 残留 =0.016%, Sr 0.10%, Ni 0.25%, Ti 0.15%, and the balance is Fe.

[0065] The production method of the low-temperature-resistant high-toughness cast ductile iron comprises the following steps:

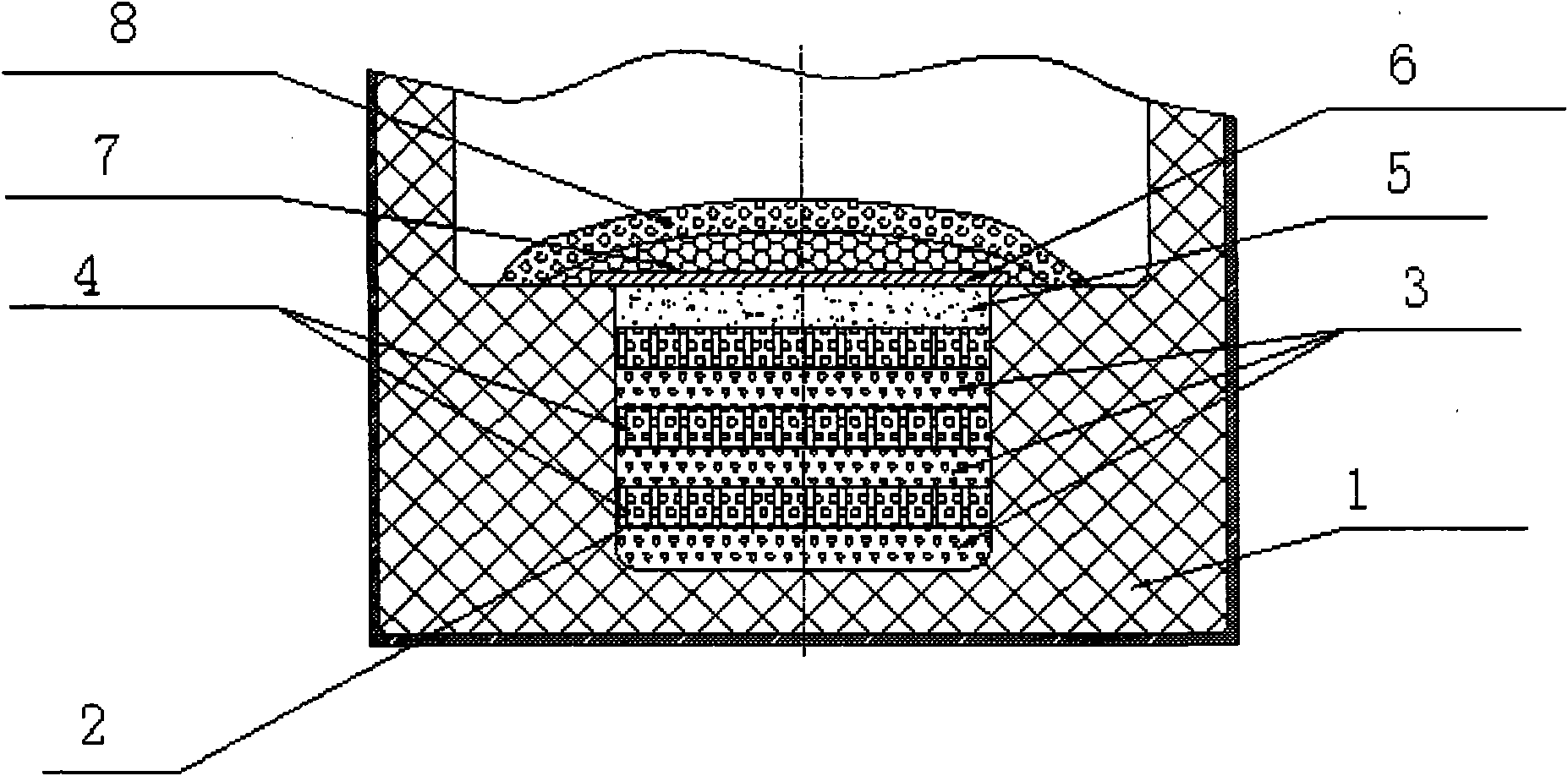

[0066] (1) Prepare the ladle and repair the bottom hole

[0067] Select a ladle with a capacity of 1 ton, and repair the refractory layer according to the conventional process (clay refractory bricks are used to lay the wall of the molten iron, and a layer of refractory dressing is applied on it. The refractory dressing is 10-15% refractory clay, 20-25% red Coal powder, the balance is 40 / 70 mesh quartz sand, add appropriate amount of water and mix to form agglomerates), in the middle of the bottom, use clay refractory bricks and refractory dressings to repair and enamell Φ350×450 cylindrical bottom nest for layere...

Embodiment 3

[0084] A low-temperature-resistant high-toughness cast ductile iron, the chemical composition of which is: C=3.4%, Si=2.3%, Mn=0.18%, P=0.019%, S=0.009%, Mg 0.036%, ΣRe=0.016%, Sr 0.10%, Ni 0.25%, Ti 0.15%, and the balance is Fe.

[0085] The production method of the low-temperature-resistant high-toughness cast ductile iron comprises the following steps:

[0086] (1) Prepare the ladle and repair the bottom hole

[0087] Select a ladle with a capacity of 1 ton, and repair the refractory layer according to the conventional process (clay refractory bricks are used to lay the wall of the molten iron, and a layer of refractory dressing is applied on it. The refractory dressing is 10-15% refractory clay, 20-25% red Coal powder, the balance is 40 / 70 mesh quartz sand, add appropriate amount of water and mix to form agglomerates), in the middle of the bottom, use clay refractory bricks and refractory dressings to repair and enamell Φ350×450 cylindrical bottom nest for layered preload...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com