Iron openwork beating device

A technology for making iron flowers and molten iron, which can be used in fireworks, offensive equipment, weapon types, etc., and can solve the problems of high personal danger and small coverage of iron flowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

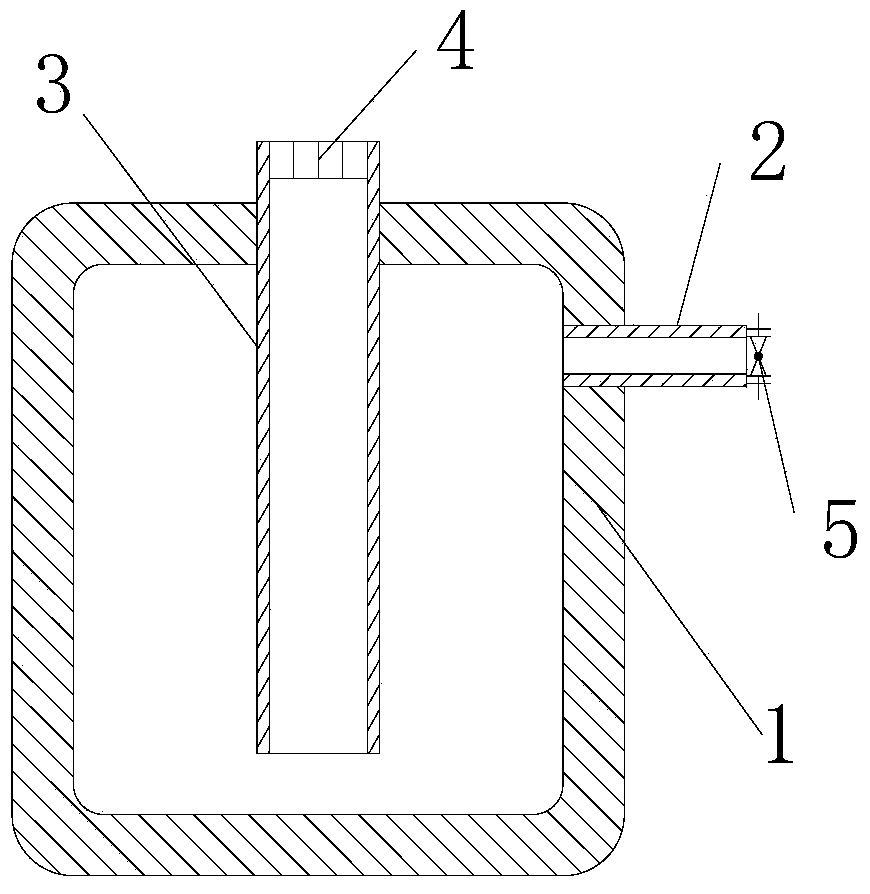

[0027] Such as figure 1 As shown, the blacksmithing device provided by the present invention includes a melting furnace 1, a first molten iron injection pipe 3, and a first high-pressure gas inlet pipe 2. The molten iron is located in the melting furnace 1, and the first high-pressure gas inlet pipe 2 communicates with the melting furnace 1. The position where the first high-pressure gas inlet pipe 2 is connected to the furnace 1 is higher than the level of the molten iron in the furnace 1, the first high-pressure gas inlet pipe 2 is provided with a first control valve 5, and the first molten iron injection pipe 3 is installed on the top of the furnace 1 , the first molten iron injection pipe 3 communicates with the molten iron in the furnace 1 . Certainly, the first high-pressure gas inlet pipe 2 is provided with high-pressure gas by an air compressor or other conventional high-pressure gas generating devices, and a nozzle 4 may be provided at the top of the first molten iron...

Embodiment 2

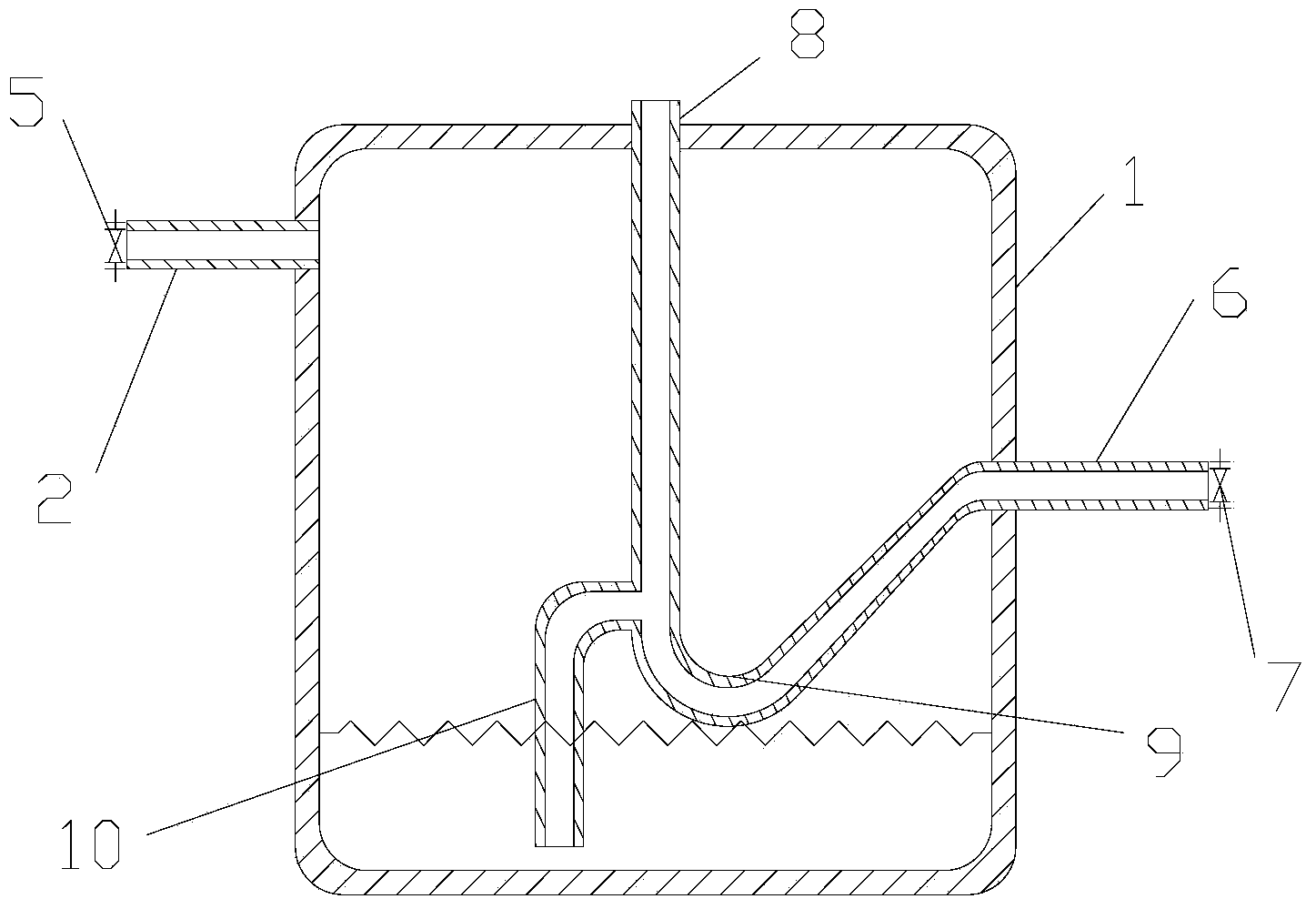

[0031] Such as figure 2 As shown, on the basis of Embodiment 1, Embodiment 2 further provides another way of forging iron flowers, which specifically includes a second high-pressure gas inlet pipe 6 pierced on the side wall of the furnace 1, and the second high-pressure gas enters The air pipe 6 is provided with a second control valve 7. The first molten iron injection pipe 3 includes an injection pipe body 8, a U-shaped pipe portion 9 and a connecting branch pipe 10. One end of the U-shaped pipe portion 9 is connected to the nozzle body 8. The bottom end is connected, and the other end is connected with the second high-pressure gas inlet pipe 6. One end of the connecting branch pipe 10 is connected to the side wall of the injection pipe body 8, and the other end is submerged in molten iron; specifically, the connecting branch pipe 10 One end is connected to a position close to the connection between the spray pipe body 8 and the U-shaped pipe part 9 . Certainly, the second ...

Embodiment 3

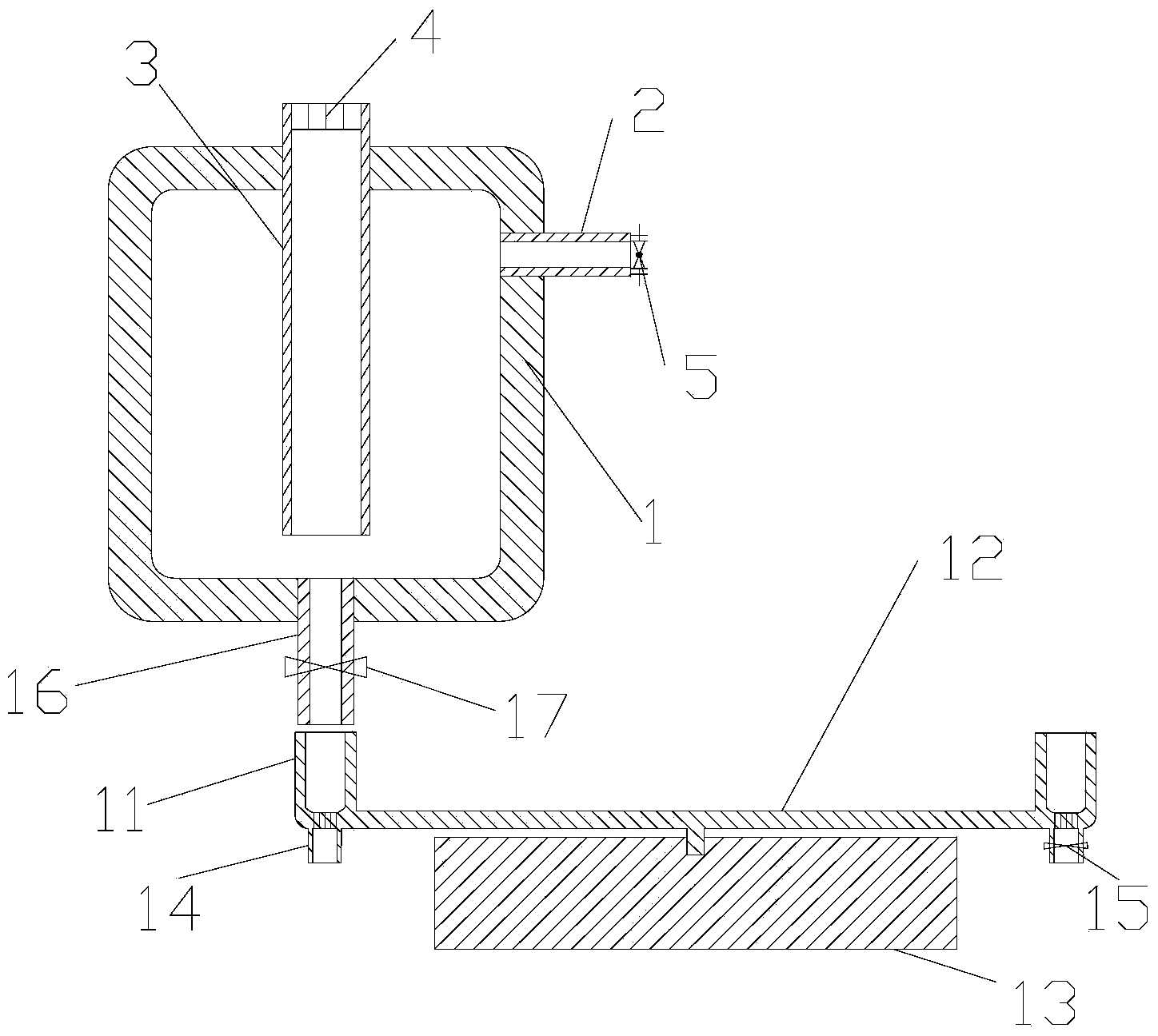

[0034] Embodiment 3 also provides a kind of iron flower device, the molten iron outflow pipe 16 is set at the bottom of the furnace 1 of embodiment 1 and embodiment 2, and the fourth control valve 17 is set on the molten iron outflow pipe 16, and it also includes support 13, is arranged on The swing arm 12 on the support 13 and the drive unit of the swing arm 12, the two ends of the swing arm 12 are provided with the second molten iron injection pipe 11 for containing molten iron, the middle part of the swing arm 12 is hinged on the top of the support 13, the swing arm 12 drive unit and The middle part of the swing arm 12 is connected, and one end of the molten iron outflow pipe 16 is connected on the melting furnace 1, and the other end is above the second molten iron injection pipe 11 at one end of the swing arm 12. Like this, molten iron can flow into the second molten iron injection pipe 11 at one end of the swing arm 12 through the molten iron outflow pipe 16 .

[0035]Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com