All-purpose hydroturbine

A water turbine, an all-round technology, applied in the field of hydraulic machinery, can solve the problems of kinetic energy loss, benefit, clean, cheap and renewable water energy resource loss, and achieve the effect of reducing the number of sets and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

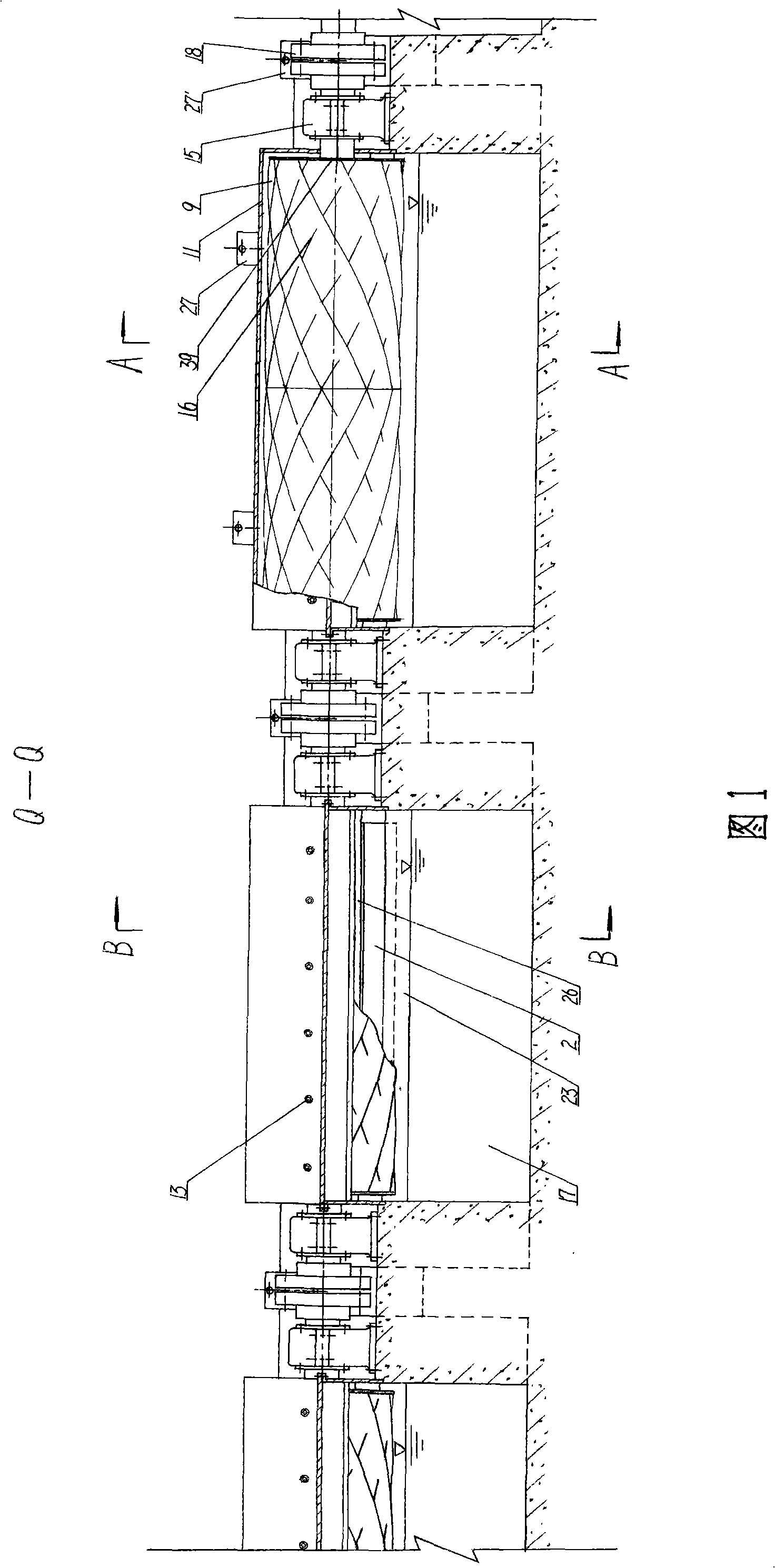

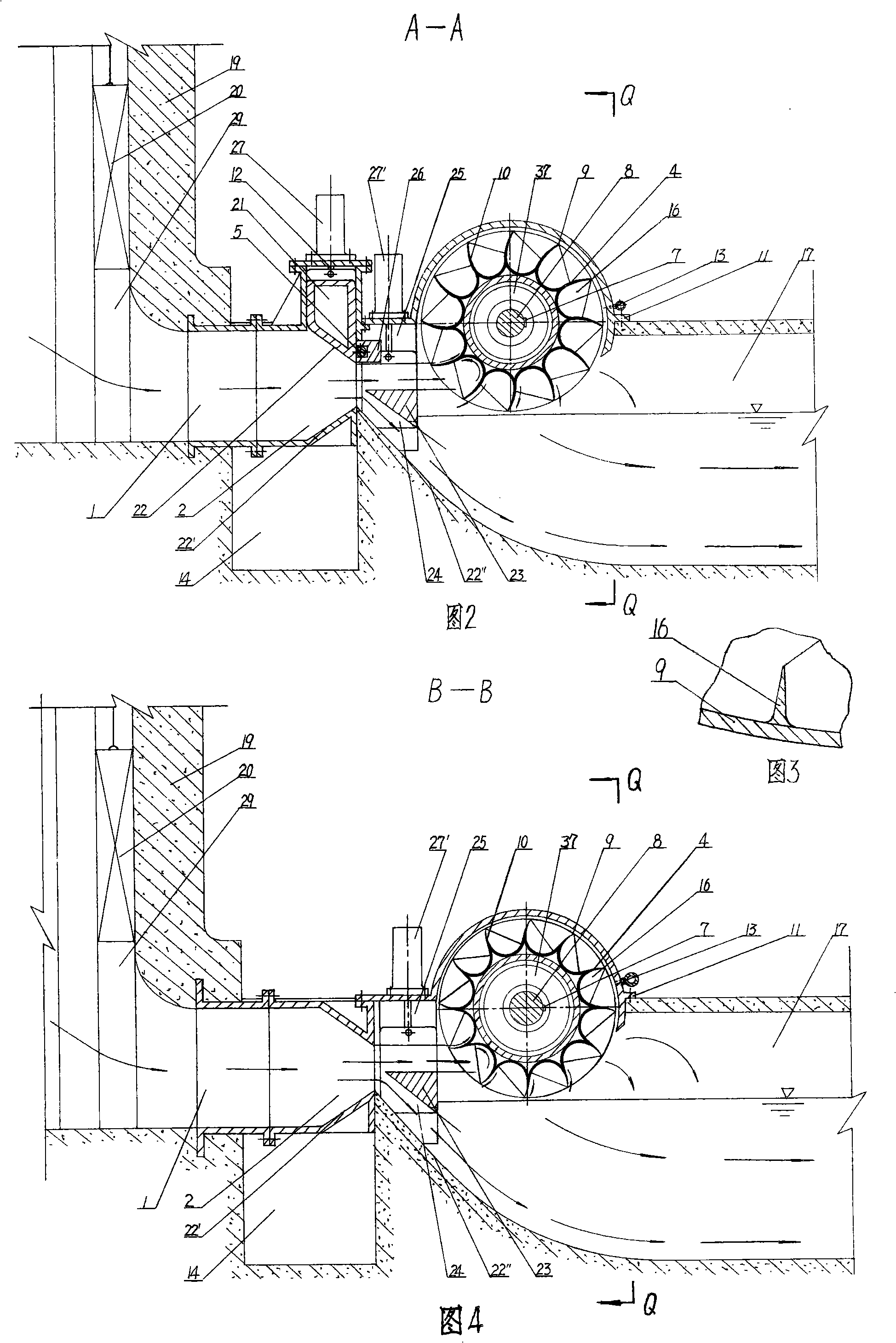

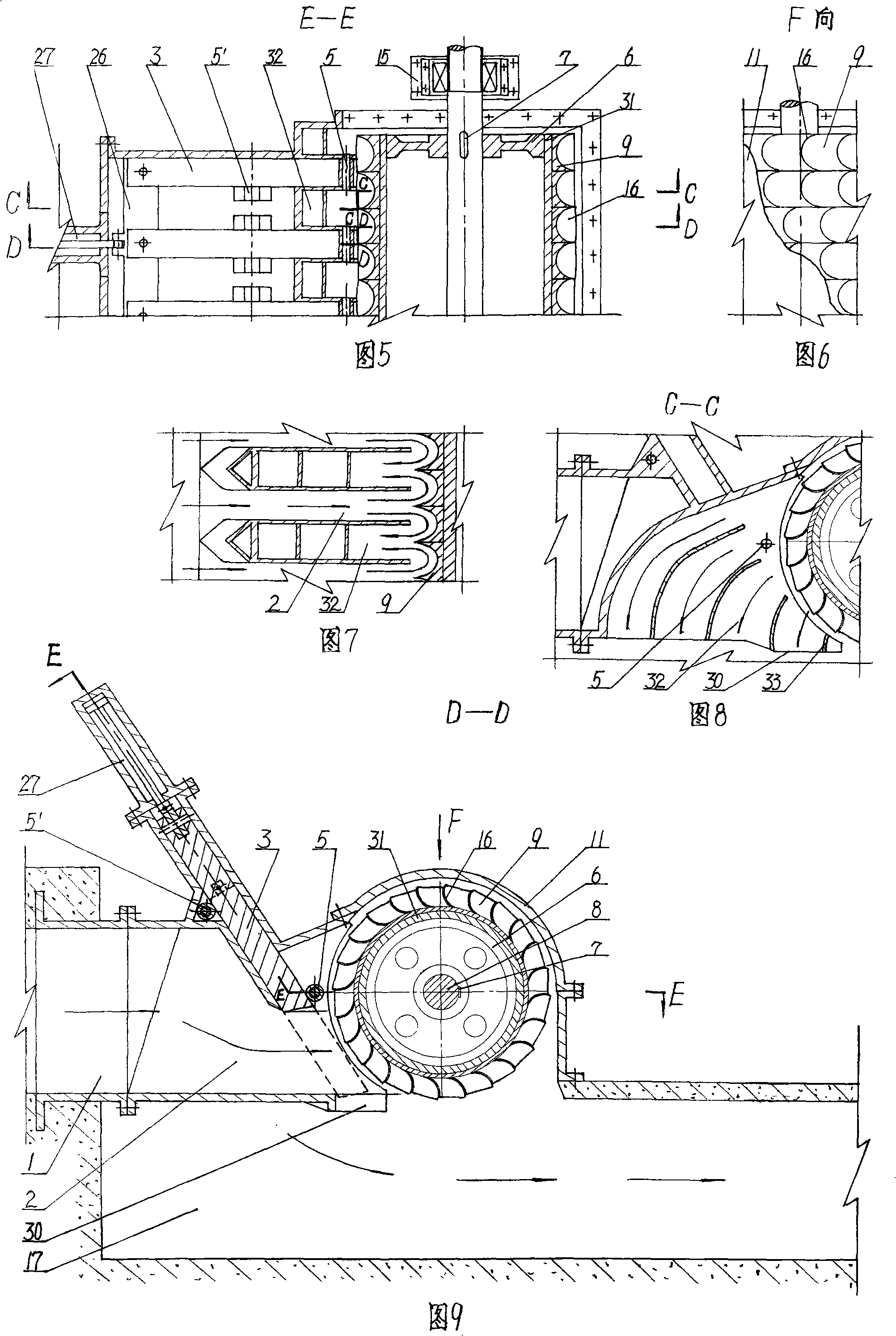

[0040] Figures 1, 2, 3 and 4 show a first embodiment of the invention.

[0041] As shown in Figure 1: In this embodiment, the main shafts of three all-purpose water turbines are sequentially connected to drive a generator, and the water turbines are numbered as No. 1 all-purpose water turbine and No. 2 all-purpose water turbine from right to left. and No. 3 Almighty Water Turbine. Among the three turbines, except for No. 1 Almighty Turbine, which has an adjusting mechanism, the jet ports of No. 2 and No. 3 turbines are not equipped with an adjusting mechanism, but are directly set as rectangular jet ports with drainage surfaces. , and the water inlets in front of the pressure diversion chamber connected with the rectangular jet port are respectively equipped with water inlet gates. A water inlet gate is also installed in front of the pressure diversion chamber of the No. 1 universal turbine, which is used as a special gate for maintenance of the No. 1 universal turbine.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com