Open stope-caving combined mining method

A mining method and empty field technology, which can be used in surface mining, underground mining, special mining, etc., can solve problems such as ore loss and dilution, and achieve the effects of low loss and dilution, simple process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

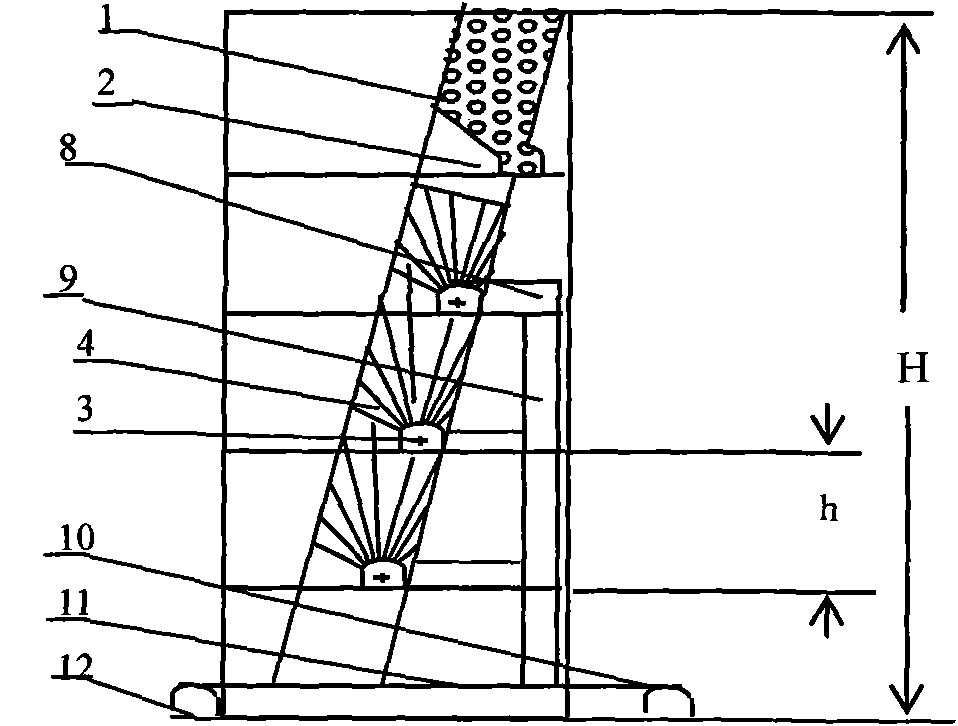

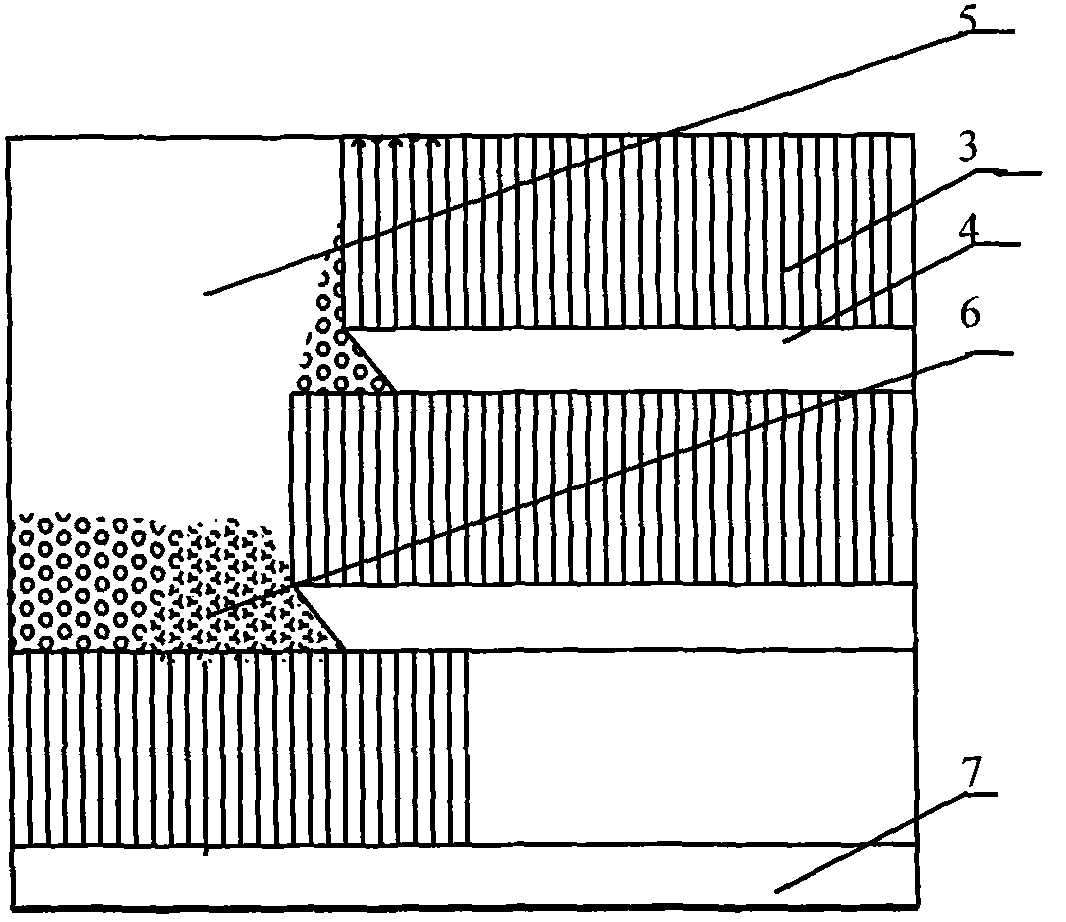

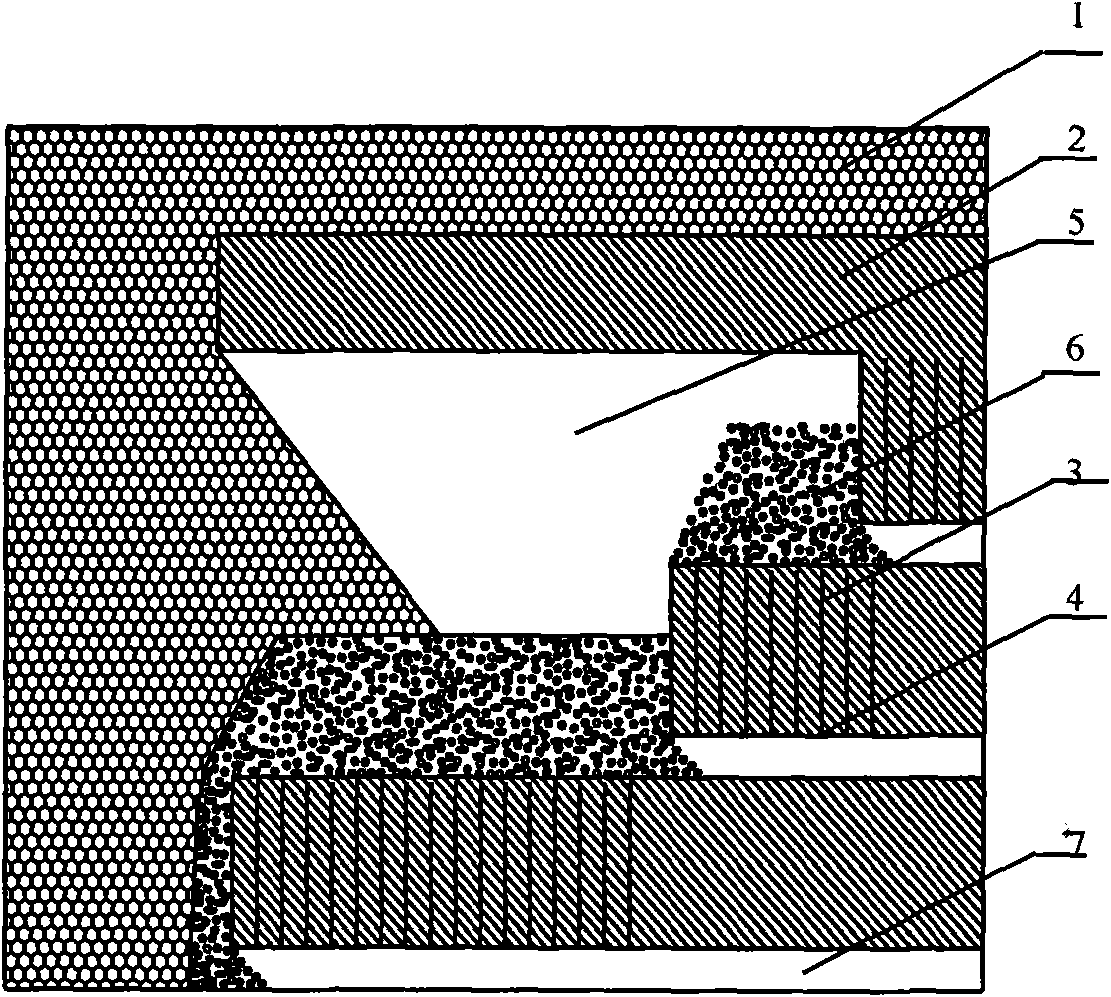

[0014] Such as figure 1 , figure 2 , image 3 As shown, each mining ore block of the present invention is composed of a top pillar, and an empty field falling section and its roadway arranged along the ore body direction, a caving recovery section and its roadway, and a mine shaft.

[0015] In the present invention, the segmental mining of the next empty field ore falling lags behind the previous section by 5-10m, and the ore is extracted in the empty field by the segmented ore until the end mouth is slightly open; Design the location of the mining approach along the vein according to the principle of conformity with the shape of the block, and draw the ore to the cut-off grade; the operation site needs to be more than 5m away from the edge of the block landing point, and the roadway connected with the goaf should be blocked. The method of blocking is to stack Waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com