Flame-retardant antistatic rubber material for conveying belt covering layer and preparation method of rubber material

A flame-retardant, anti-static, rubber material technology, applied in the field of rubber materials, can solve the problems of easy fire, easy accumulation of large static electricity, safety, etc., and achieve the effect of improving flame-retardant and anti-static effects and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

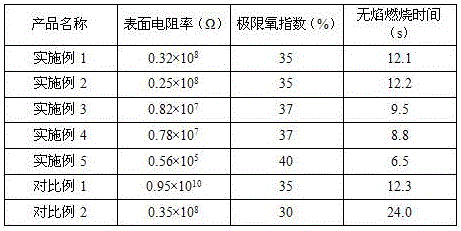

Examples

Embodiment 1

[0022] A rubber material for a flame-retardant and antistatic conveyor belt covering layer, which is prepared from the following components in parts by weight: 40 parts of neoprene rubber, 70 parts of styrene-butadiene rubber, 2 parts of sulfur, 50 parts of carbon black, ethyl tri-( 1.5 parts of 2-methoxyethoxy) silane, 10 parts of zinc stearate, 1 part of accelerator, 2 parts of anti-aging agent, 30 parts of dicyclopentadiene resin, octadecyl dimethyl hydroxyethyl quaternary 6 parts of ammonium nitrate, 4 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 8 parts of stearamidopropyl dimethyl-β-hydroxyethyl ammonium dihydrogen phosphate, 5 parts of aluminum hydroxide, bis 1 part of (2,3-dibromopropyl)fumarate, 5 parts of 1,2-bis(2,4,6-tribromophenoxy)ethane.

[0023] The preparation method of the above-mentioned rubber material for the cover layer of the flame-retardant and antistatic conveyor belt is as follows: (1) masticating neoprene and butadiene rubber on...

Embodiment 2

[0025] A rubber material for a flame-retardant and antistatic conveyor belt cover layer, which is prepared from the following components in parts by weight: 50 parts of neoprene rubber, 50 parts of styrene-butadiene rubber, 5 parts of sulfur, 30 parts of carbon black, and ethyl tri-(2 -3 parts of methoxyethoxy) silane, 4 parts of zinc stearate, 2 parts of accelerator, 4 parts of antioxidant, 40 parts of dicyclopentadiene type resin, octadecyl dimethyl hydroxyethyl quaternary ammonium 3 parts of nitrate, 8 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 4 parts of stearamidopropyl dimethyl-β-hydroxyethyl ammonium dihydrogen phosphate, 1 part of aluminum hydroxide, bis( 5 parts of 2,3-dibromopropyl)fumarate, 1 part of 1,2-bis(2,4,6-tribromophenoxy)ethane.

[0026] The preparation method of the above-mentioned rubber material for the cover layer of the flame-retardant and antistatic conveyor belt is as follows: (1) masticating neoprene and butadiene rubber on a...

Embodiment 3

[0028] A rubber material for a flame-retardant and antistatic conveyor belt cover layer, which is prepared from the following components in parts by weight: 48 parts of neoprene rubber, 65 parts of styrene-butadiene rubber, 3 parts of sulfur, 35 parts of carbon black, ethyl tri-( 2 parts of 2-methoxyethoxy) silane, 8 parts of zinc stearate, 1.2 parts of accelerator, 3 parts of anti-aging agent, 35 parts of dicyclopentadiene resin, octadecyl dimethyl hydroxyethyl quaternary 5 parts of ammonium nitrate, 5 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 5 parts of stearamidopropyl dimethyl-β-hydroxyethyl ammonium dihydrogen phosphate, 3 parts of aluminum hydroxide, bis (2,3-dibromopropyl)fumarate 3 parts, 1,2-bis(2,4,6-tribromophenoxy)ethane 4 parts.

[0029] The preparation method of the above-mentioned rubber material for the cover layer of the flame-retardant and antistatic conveyor belt is as follows: (1) masticating neoprene and butadiene rubber on an intern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com