Degradable unsaturated polyesteramide resin and synthesis method thereof

A technology of polyester amide and synthesis method, which is applied in the field of polymer materials, can solve the problems of consumption of forest resources, pollution application, incomplete degradation, etc., and achieve the effect of reducing soil alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

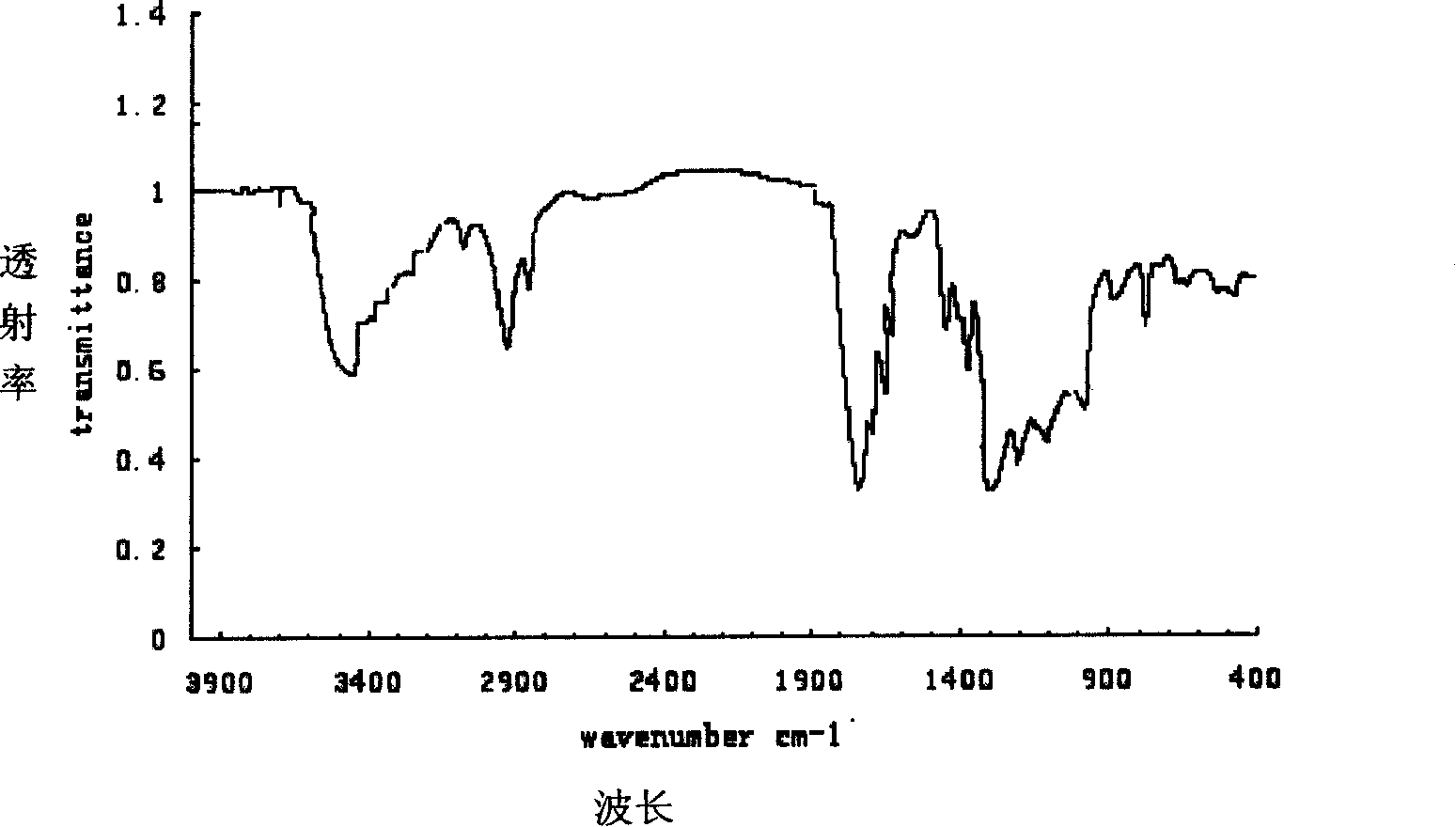

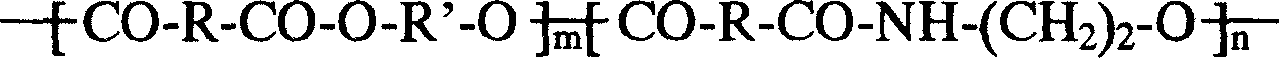

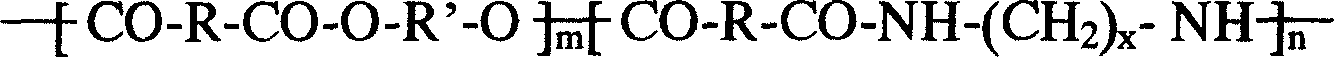

Image

Examples

Embodiment 1

[0033] Embodiment 1: One of the synthetic methods of unsaturated polyester amide resin:

[0034] Mix 0.40 mol of maleic anhydride, 0.1 mol of ethanolamine and 0.31 mol of ethylene glycol, put it into a 250ml three-necked flask with a water separator, place it in a silicone oil bath, stir it electrically, and react at 100°C for 20 minutes. The temperature was raised to 150° C. for 40 minutes for melt polymerization in a nitrogen atmosphere, then the temperature was raised to 180° C. for 120 minutes for melt polymerization in a nitrogen atmosphere, and then the temperature was raised to 200° C. for 120 minutes for melt polymerization in a nitrogen atmosphere. When the distilled reaction water reaches 80% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C., and poured out. After cooling, a light brown transparent semi-solid unsaturated polyester amide resin is obtained.

Embodiment 2

[0035] Embodiment 2: two of the synthetic method of unsaturated polyester amide resin:

[0036] Mix 0.40 mol of maleic anhydride, 0.1 mol of hexamethylenediamine and 0.33 mol of ethylene glycol, put it into a 250ml three-necked flask with a water separator, place it in a silicone oil bath, stir it electrically, and react at 100°C for 20 minutes. Heating up to 150°C, melt polymerization in a nitrogen atmosphere for 40 minutes, then raising the temperature to 180°C, melt polymerization in a nitrogen atmosphere for 120 minutes, then raising the temperature to 200°C, melt polymerization in a nitrogen atmosphere for 60 minutes, and melt polymerization in a nitrogen atmosphere for 60 minutes. When the distilled reaction water reaches 80% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C., and poured out. After cooling, a light brown transparent semi-solid unsaturated polyester amide resin is obtained.

Embodiment 3

[0037] Embodiment 3: three of the synthetic method of unsaturated polyester amide resin:

[0038] Mix 0.40 mol of maleic anhydride, 0.2 mol of lysine and 0.44 mol of ethylene glycol, put it into a 250ml three-neck flask with a water separator, place it in a silicone oil bath, stir it electrically, and react at 120°C for 60 minutes. Heating up to 150°C, melt polymerization in a nitrogen atmosphere for 60 minutes, then raising the temperature to 180°C, melt polymerization in a nitrogen atmosphere for 120 minutes, then raising the temperature to 200°C, melt polymerization in a nitrogen atmosphere for 60 minutes, and melt polymerization in a nitrogen atmosphere for 60 minutes. When the distilled reaction water reaches 90% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C., and poured out. After cooling, a light brown transparent semi-solid unsaturated polyester amide resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com