Sand ratio detection method for fracturing operation of oil and gas exploitation

A technology of oil and gas exploitation and detection method, which is applied in volume flow ratio measurement, measurement device, liquid/fluid solid measurement, etc. It can solve the problems of low detection accuracy, expensive nucleon density meter, and difficult to meet the needs of actual use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

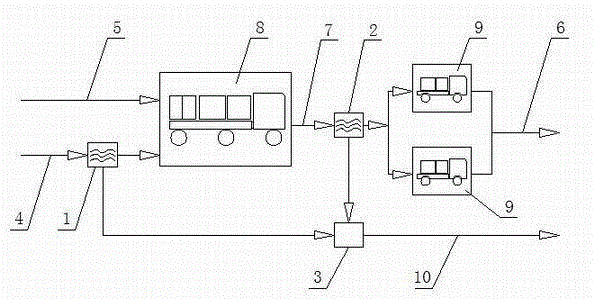

[0015] The essence of the detection of sand ratio in fracturing operations such as oil and oil and gas, and coalbed methane is to detect the ratio of sand and other solid particles in the fluid during the sand-carrying liquid stage during the fracturing process. The detection device used in the detection method of the present invention includes a fluid flow meter 1 at the inlet of the sand mixing equipment, a fluid flow meter 2 at the outlet of the sand mixing equipment and a sand ratio calculation system 3 . The sand mixing equipment inlet fluid flow meter 1 is used to detect the sand mixing equipment inlet fluid flow L1, and the sand mixing equipment outlet fluid flow meter 2 is used to detect the sand mixing equipment outlet fluid flow L2; the sand ratio calculation system 3 can be composed of a single chip computer system or It is composed of other computer systems, and its output interface can be a serial digital interface such as RS232, RS485, CAN bus, or an analog signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com