Method and equipment of vacuum catalytic cracking for preparing limonene, fuel oil and carbon black from scrap tire

A catalytic cracking and limonene technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, fibrous fillers, etc., to achieve the effect of shortening the reaction time and lowering the cracking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

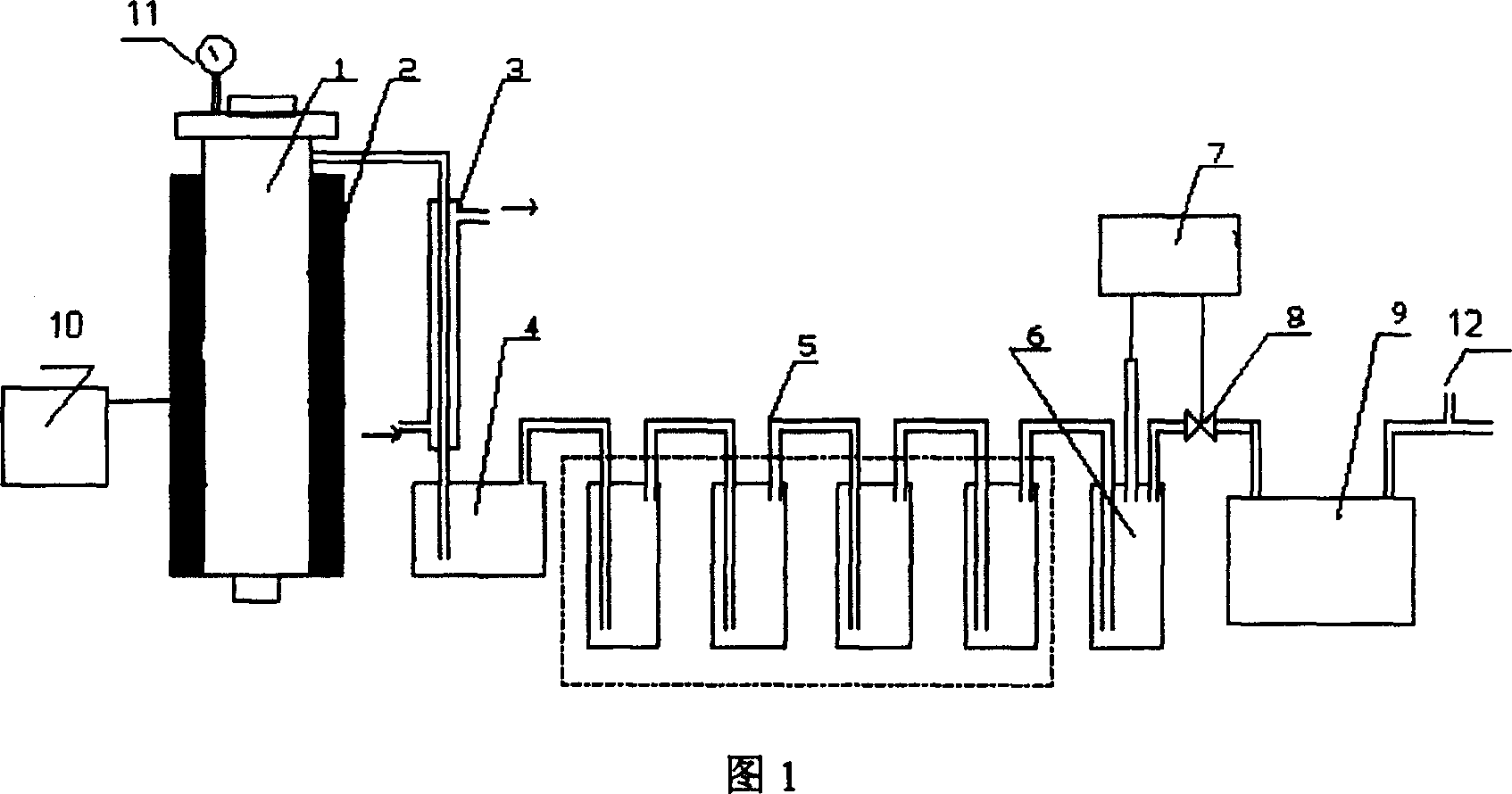

[0014] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment:

[0015] Mix sodium hydroxide NaOH and zinc oxide ZnO with a weight ratio of 1.2: 1 to make a catalyst, add waste tire particles and catalyst to the vacuum catalytic cracking reactor 1 in a ratio of 1000 grams: 30 grams, and the reaction temperature is controlled by an electric heating furnace 2 And temperature controller 10 is controlled at 480 ℃, and the vacuum degree of vacuum catalytic cracking reactor is controlled at 3800Pa by vacuum relay 7 and electromagnetic valve 8, shows in vacuum pressure gauge 11, and the residence time of waste tire in vacuum catalytic cracking reactor is 23 Minutes, under the conditions described above, the waste tire particles undergo a catalytic cracking reaction, and the resulting mixed gas passes through the primary condenser 3 to condense the organic vapor and water vapor into a liquid, and collects it in the liquid collector 4, lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com