Preparation method of high-viscosity rosin resin

A rosin resin and high-viscosity technology, applied in the field of tackifying resins, can solve the problems of low viscosity, difficult use, inconvenient use for downstream users, etc., and achieve the effect of convenient use and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

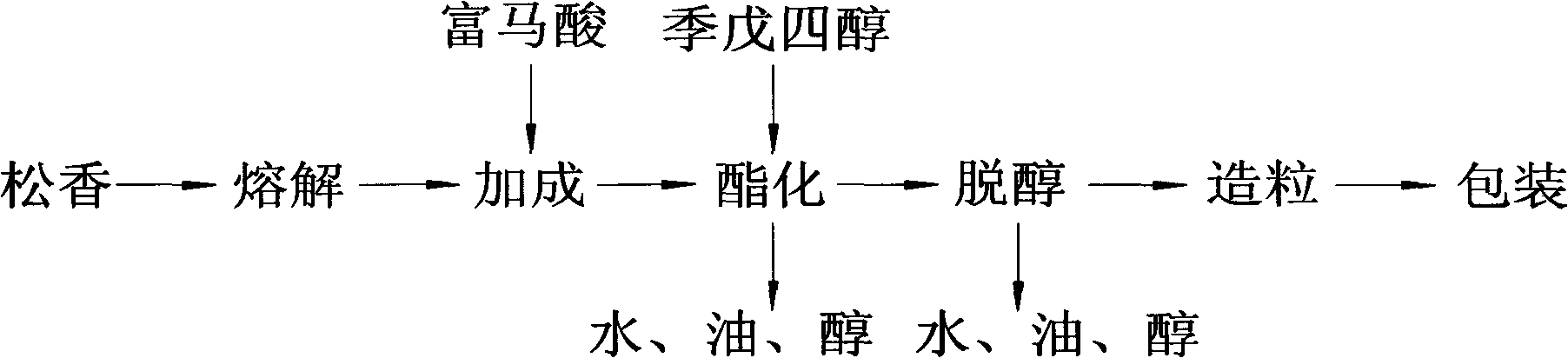

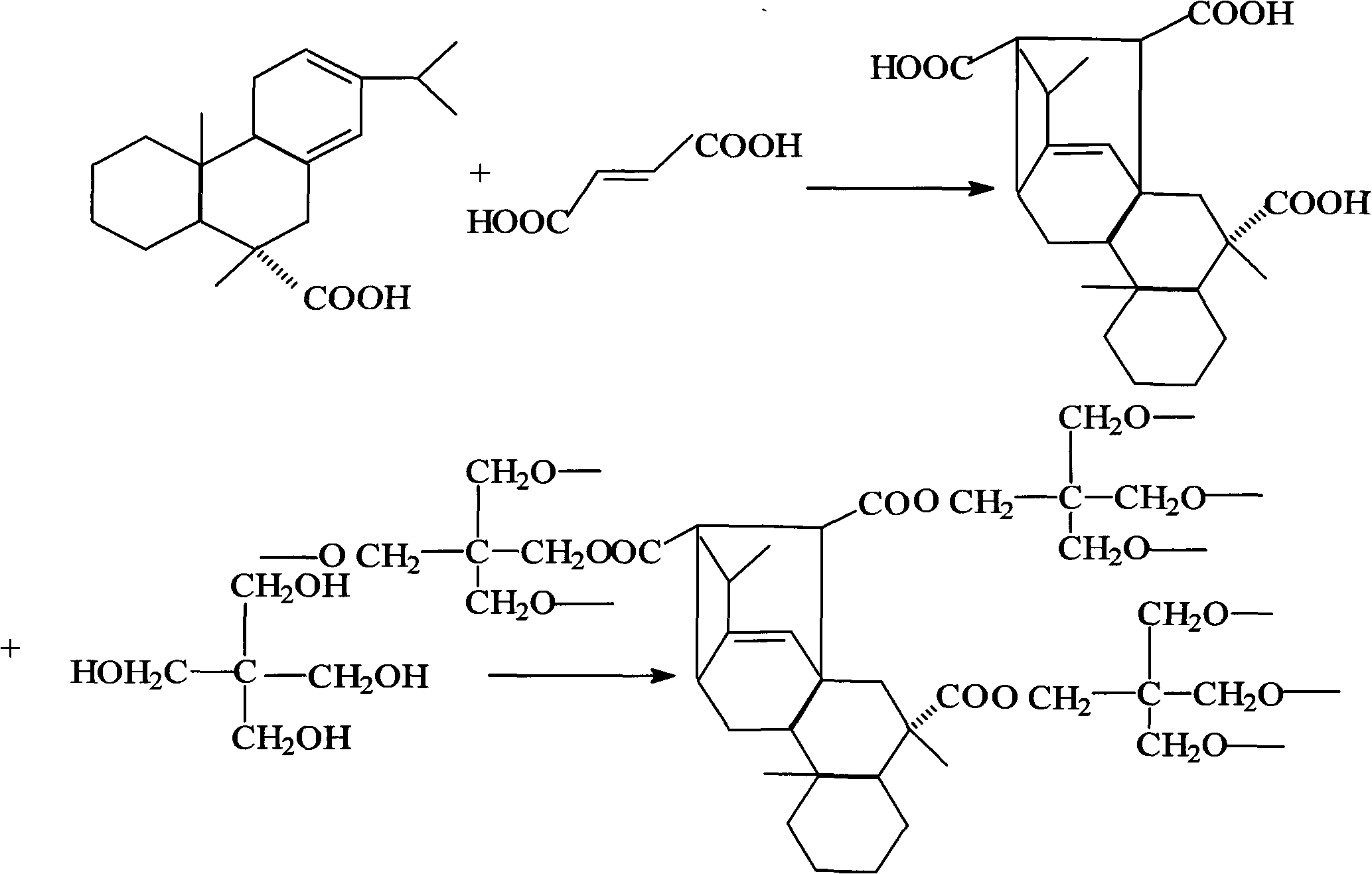

[0012] The preparation method of the high-viscosity rosin resin comprises the following raw materials in percentage by weight: 85% of masson pine extra-grade rosin, 2.8% of fumaric acid (also known as fumaric acid), and 12.2% of pentaerythritol. Add 85% (weight) rosin into the melting kettle and heat to 230°C to melt. Then inhale in the reactor, cool down to 195°C, add 2.8% (weight) of fumaric acid, heat preservation reaction, when the softening point reaches 90-95°C, add 12.2% (weight) of pentaerythritol, heat up to 278°C, heat preservation React until the acid value is ≤16mg / g and the softening point reaches 110-115°C, then dealcoholization, granulation, and packaging. The technical indicators of the produced rosin resin are: acid value 15.62mg / g, softening point (ring and ball method) 113°C, viscosity 6900 centipoise / 150°C. The color (iron-cob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com