Patents

Literature

50results about How to "Guaranteed Surface Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature-resistant ultralow temperature-cured epoxy polyester powdery coating

InactiveCN103275597AReasonable formulaLow curing temperaturePowdery paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses a high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating solves the problem that the existing low temperature-cured epoxy polyester powdery coating has poor heat resistance and poor thermal conductivity so that in curing, temperatures in a coating film prepared from the existing low temperature-cured epoxy polyester powdery coating are not different and coating curing rates are not different and thus the coating film produces orange peel phenomenon and even crazes and coating film surface-effects are influenced. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating is prepared from 30 to 40wt% of epoxy resin, 15 to 20wt% of polyester resin, 0.5 to 1.5wt% of polyarylene sulfide resin, 10 to 15wt% of titanium dioxide, 2 to 5wt% of nano-metal powder subjected to surface treatment, 0.5 to 1wt% of dibutyltin dilaurate, 1 to 3wt% of an assistant, 1 to 5wt% of sodium fluoride, 15 to 20wt% of a filling material and 10 to 15wt% of a pigment. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating has a low curing temperature, good heat resistance, and physical and mechanical properties and chemical resistance satisfying industrial requirements.

Owner:HANGZHOU GOLDEAGLE PLASTIC POWDER

High-strength painted bundling belt and manufacturing method thereof

InactiveCN102978512ANot perishableSpeed up evaporationFlexible elementsLead bismuthChemical composition

The invention discloses a high-strength painted bundling belt. The high-strength painted bundling belt comprises the following chemical components by weight percent: 0.12-0.20% of C, 0.2-0.6% of Si, 1.2-2.0% of Mn, less than or equal to 0.025% of P, less than or equal to 0.02% of S and 0.01-0.05% of Nb. The high-strength painted bundling belt is prepared by the steps of smelting, casting a blank, and then carrying out hot-rolling to form coils; carrying out acid cleaning; carrying out cold rolling; uncoiling, splitting and conducting deburring; carrying out tempering treatment in a lead-bismuth furnace; carrying out water cooling; painting by adopting a dip-coating wiping mode and carrying out sectional baking; and waxing and drying by adopting hot air. The high-strength painted bundling belt disclosed by the invention has the advantages that since a proper amount of Nb is added, the influence on crystal lattice distortion caused by overlarge volume mismatching of enhanced element atoms and Fe atoms is overcome, namely a value sigma b is increased, the overhigh yielding-to-tensile ratio can be restrained, and a steel belt with high strength, good elasticity, excellent mechanical property is produced; and the energy consumption is low, the process is simple, the painted surface is uniform, the anti-rusting performance is good and the process is simple.

Owner:武钢集团有限公司

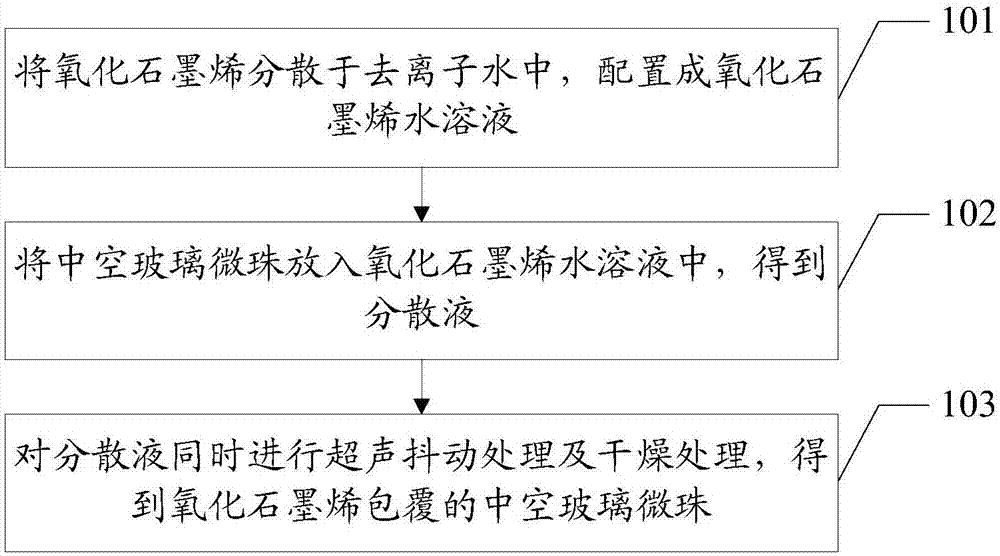

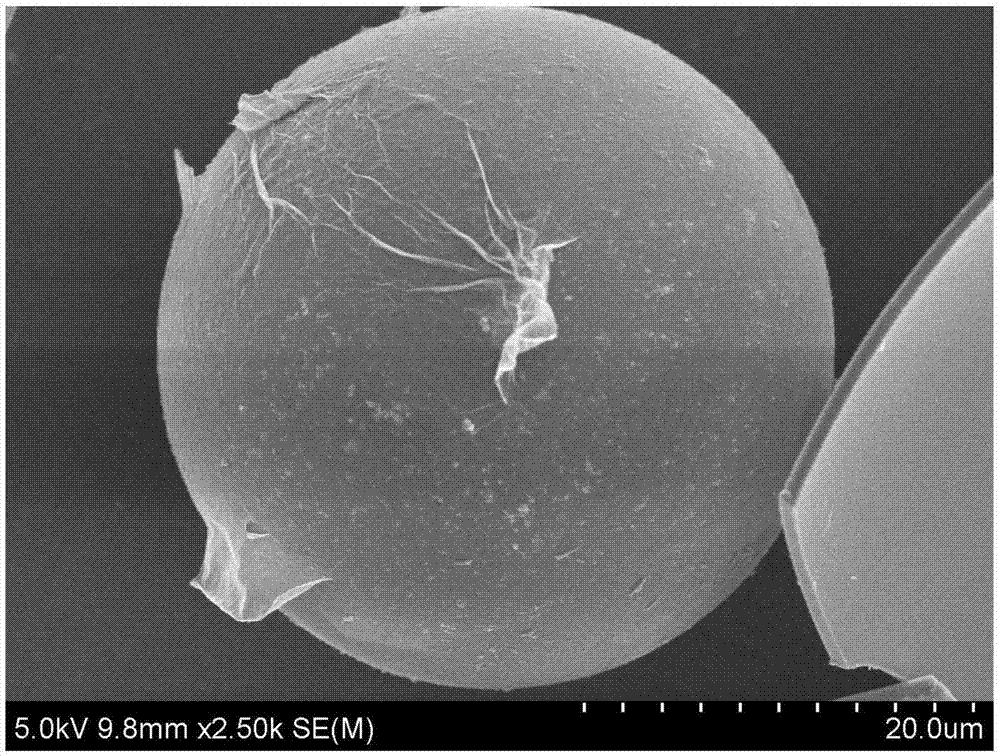

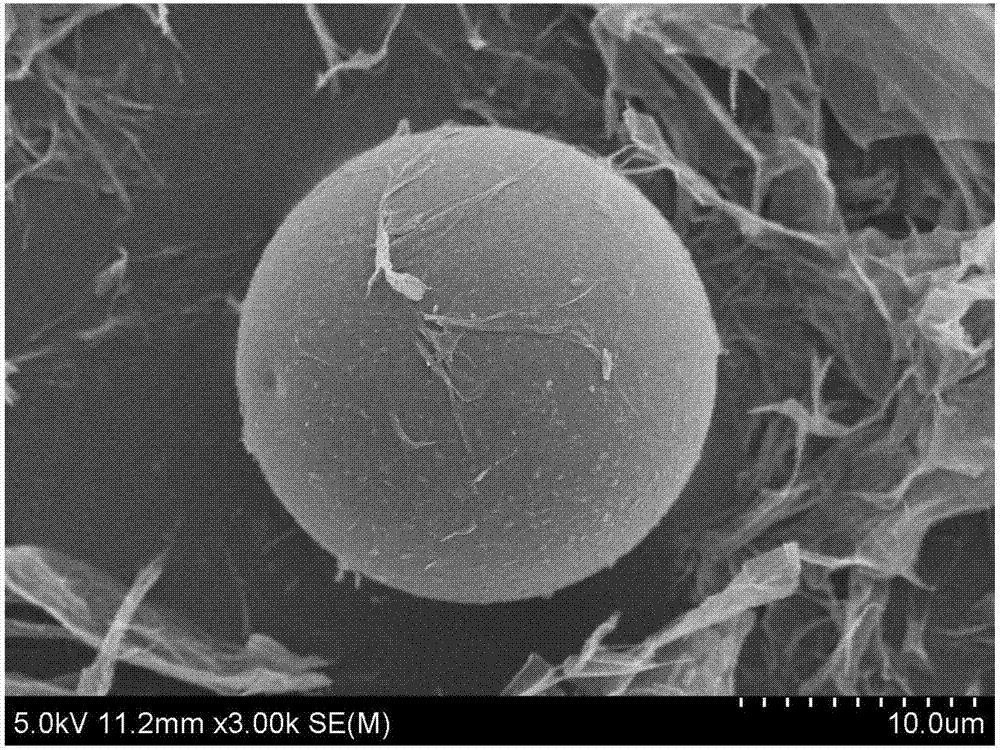

Graphene oxide coated hollow glass bead preparation method

The invention discloses a graphene oxide coated hollow glass bead preparation method. The method comprises the steps of dispersing graphene oxide into deionized water to prepare a graphene oxide watersolution, putting hollow glass beads into the graphene oxide water solution to obtain dispersion liquid, and performing ultrasonic shaking treatment and drying treatment on the dispersion liquid at the same time to obtain graphene oxide coated hollow glass beads. By means of the ultrasonic shaking treatment and drying treatment on the dispersion liquid at the same time, the surfaces of the hollowglass beads can be evenly coated with the graphene oxide; thus, other additives of adhesives are avoided, and surface performance of the hollow glass beads is kept.

Owner:SHENZHEN UNIV

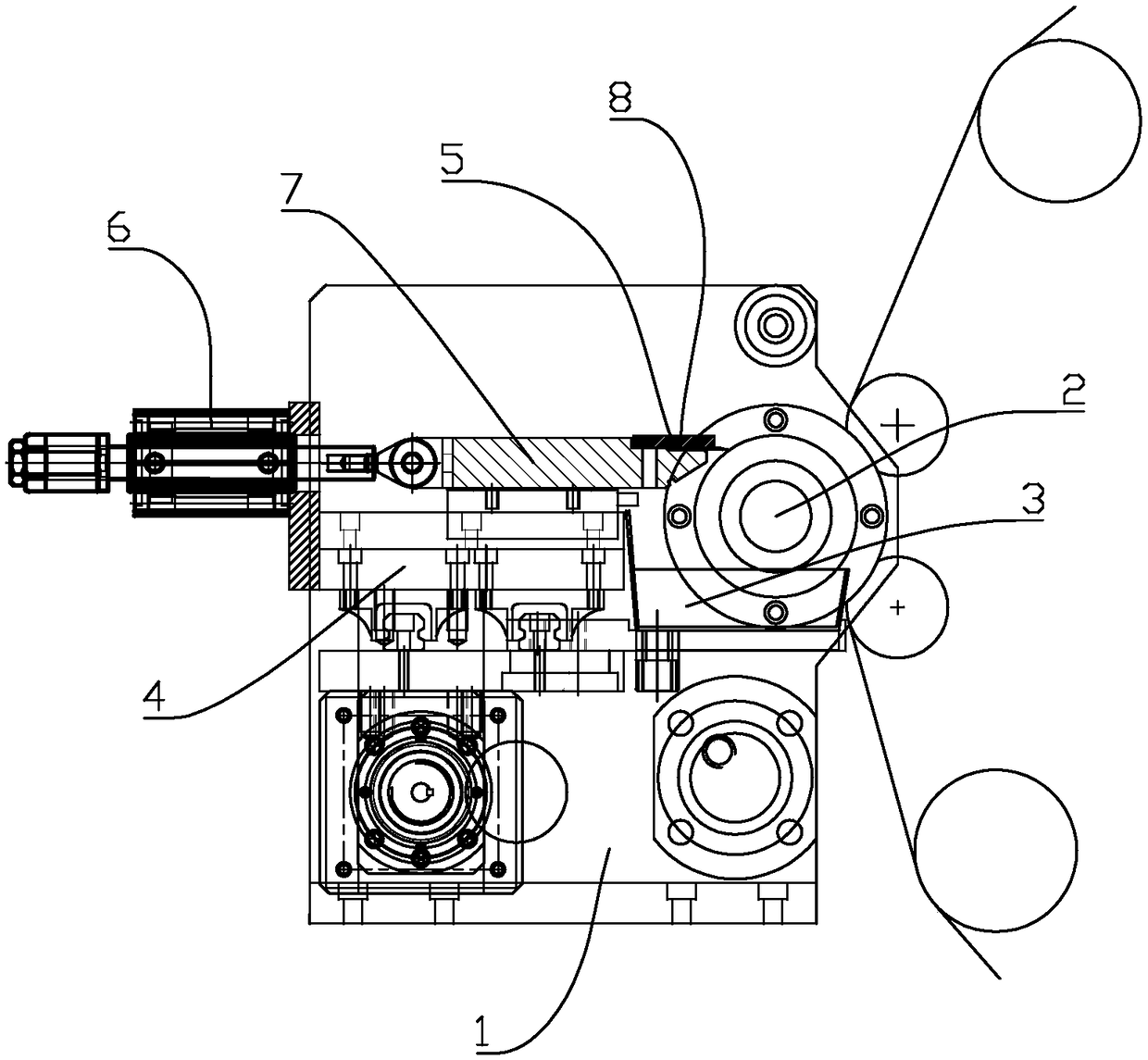

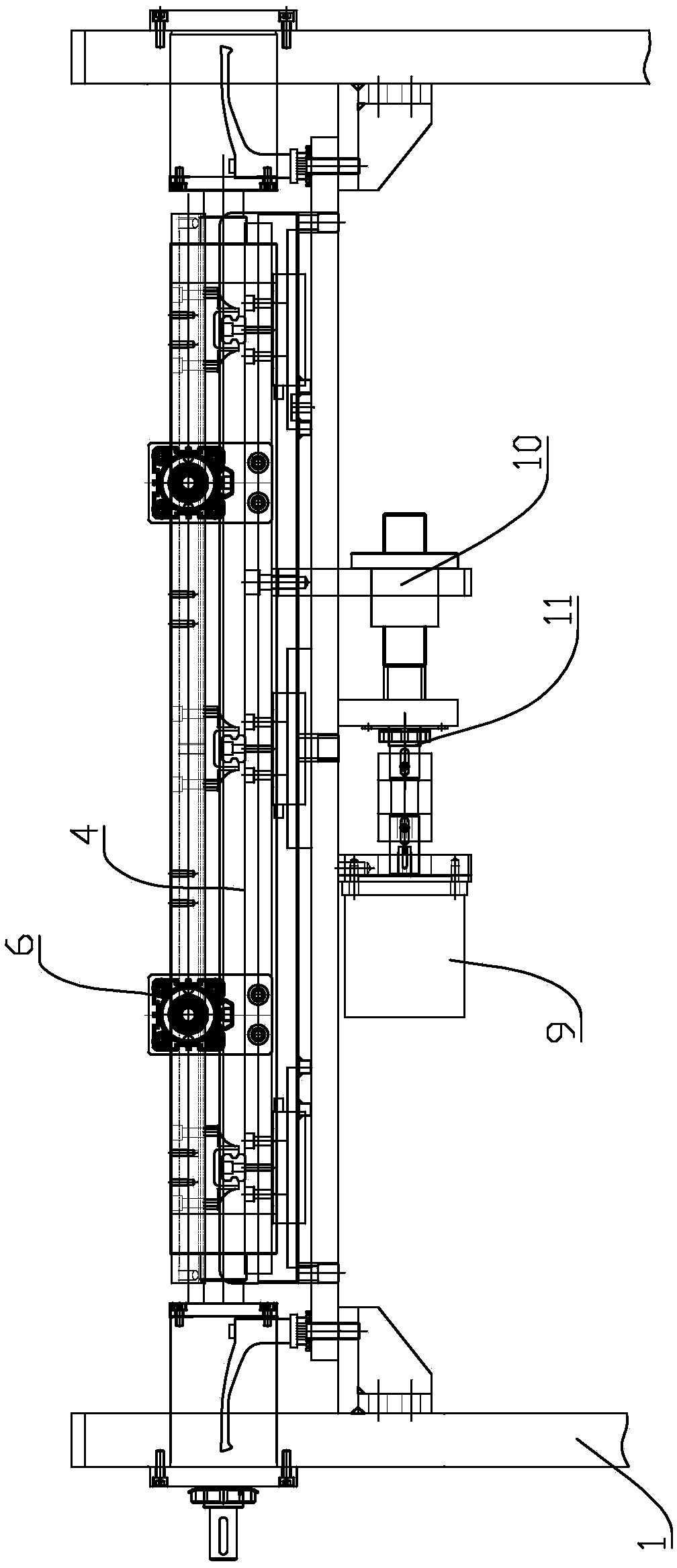

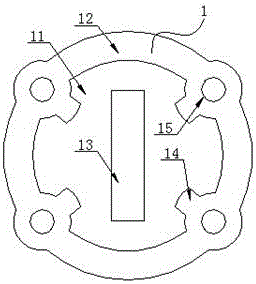

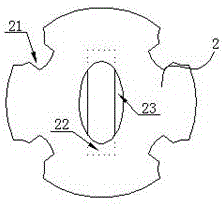

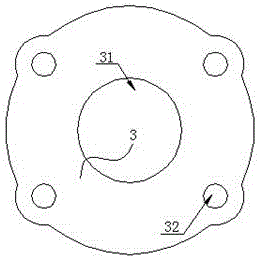

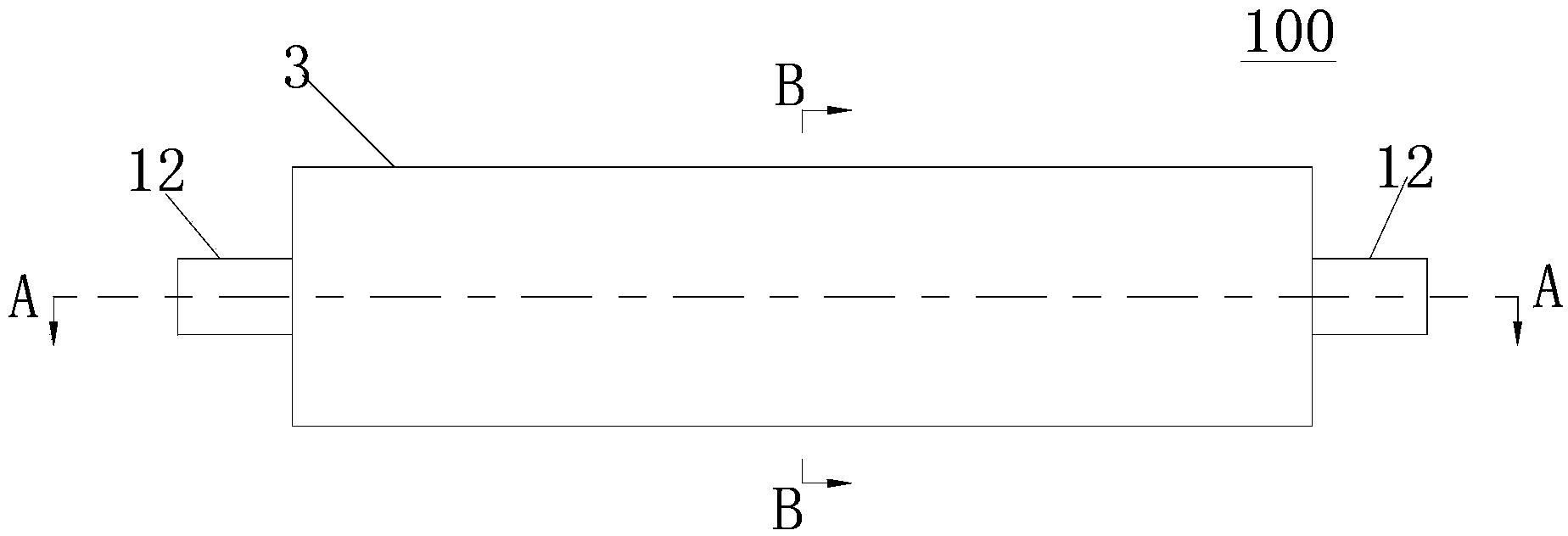

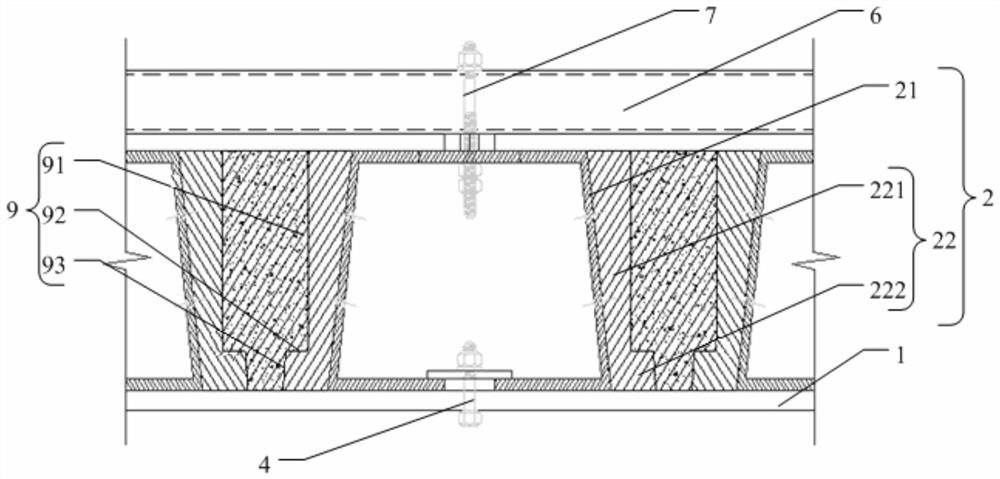

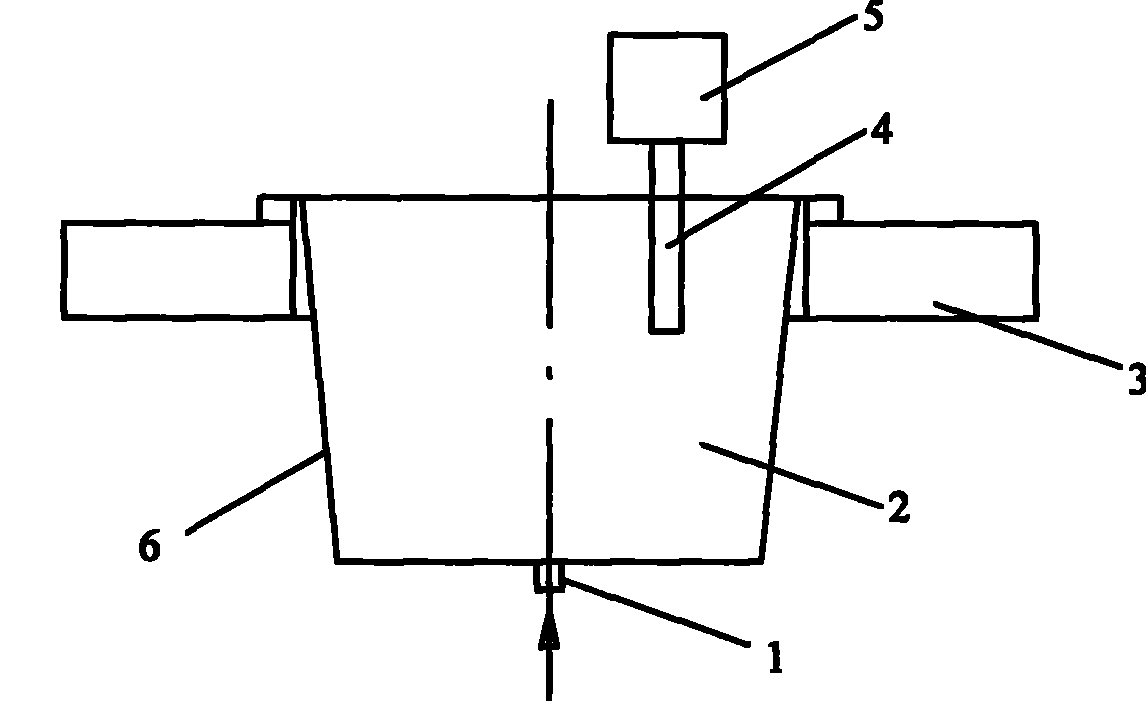

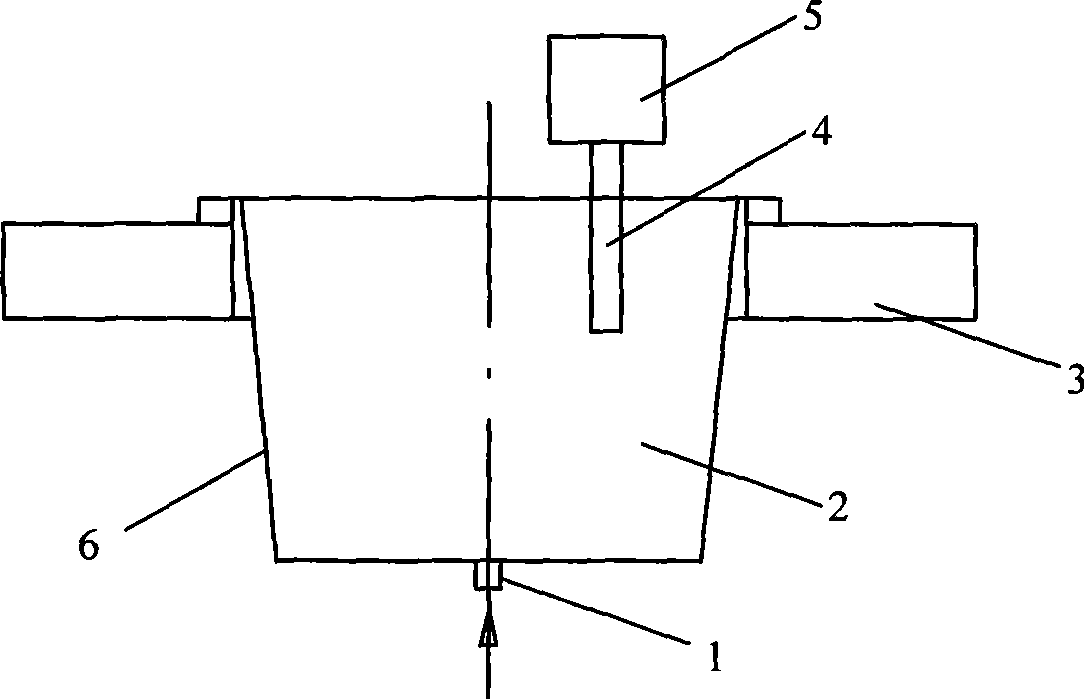

Open one-scraper structure

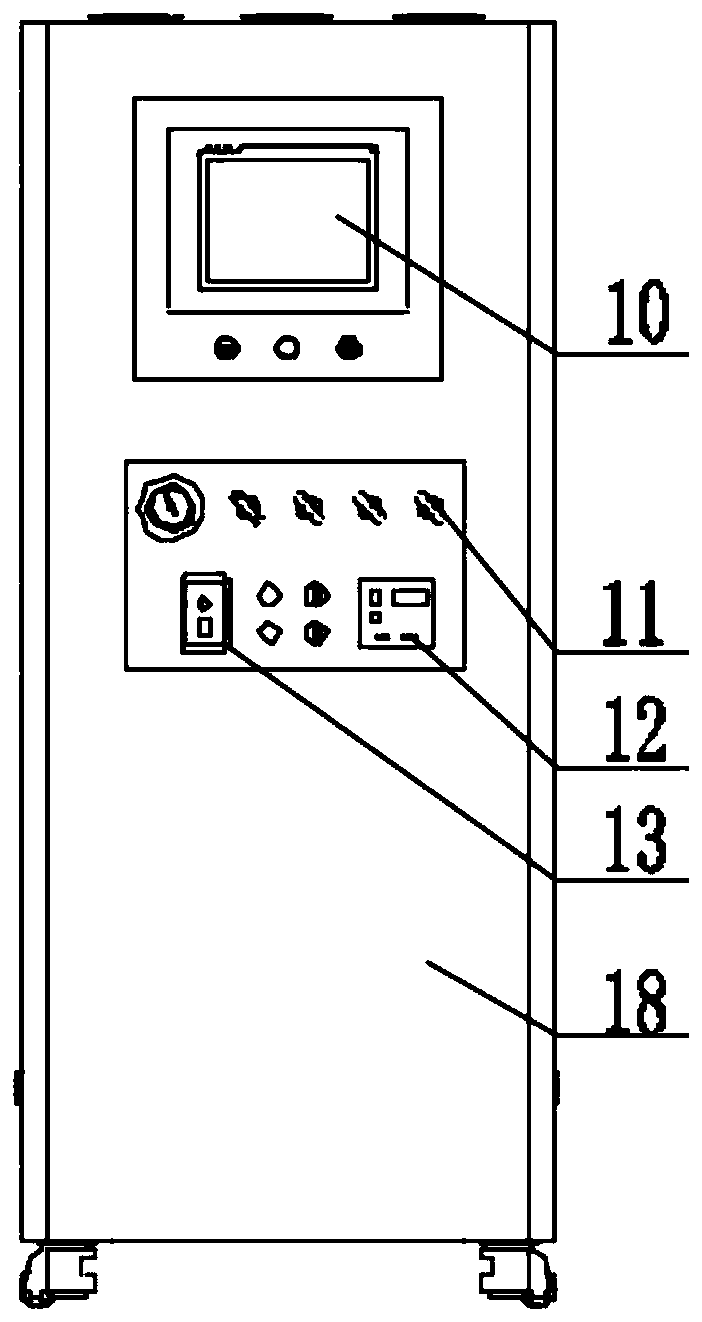

PendingCN109482417AGuaranteed Surface PropertiesSimple structureLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses an open one-scraper structure. The open one-scraper structure comprises a machine frame, a slide seat, a driving mechanism and a scraper assembly, wherein a micro concave roller is rotatably installed on the machine frame, and a material bowl is arranged below the micro concave roller; the slide seat is transversely and slidably installed on the machine frame, and the moving track of the slide seat is parallel to the center line of the micro concave roller; the driving mechanism is installed on the machine frame and used for driving the slide seat to move; and the scraper assembly is installed on the slide seat. Through the implementation mode, the slide seat is driven to slide on the machine frame through the driving mechanism, accordingly, the scraper assembly isdriven to transversely slide, even though a notch formed at the scraper edge of the scraper assembly, generated scraper lines can be removed through other complete positions of the scraper edge when the scraper assembly slides in the transverse direction, and the coating surface effect is ensured. The open one-scraper structure is simple and ingenious in structure and practical in effect.

Owner:ZHONGSHAN SONGDE NEW MATERIAL EQUIP CO LTD

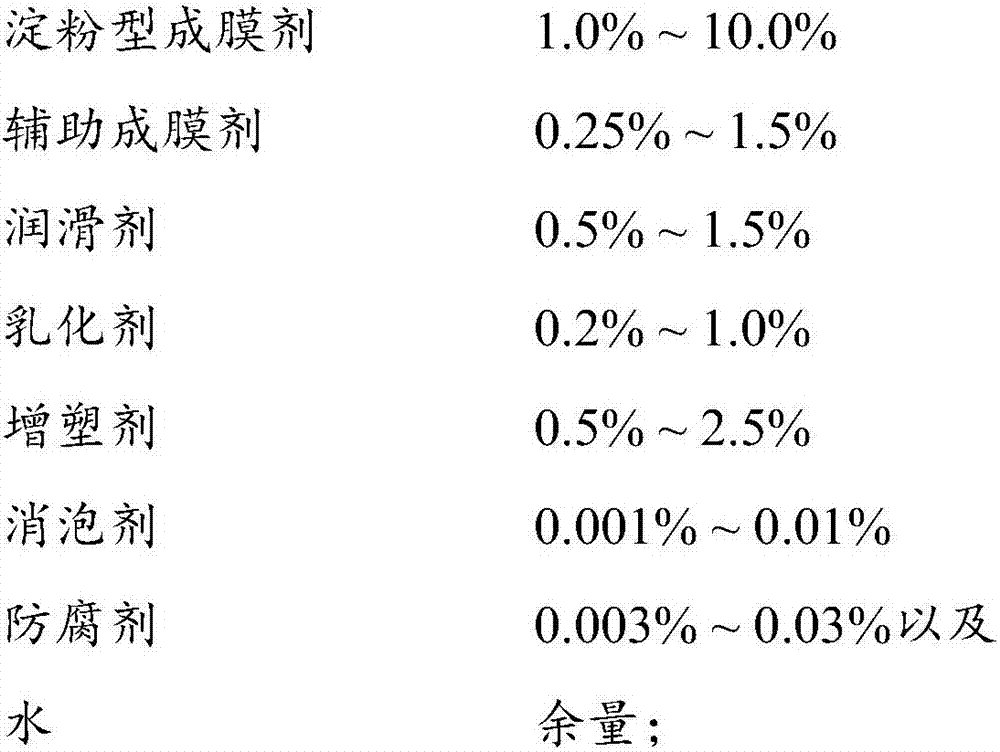

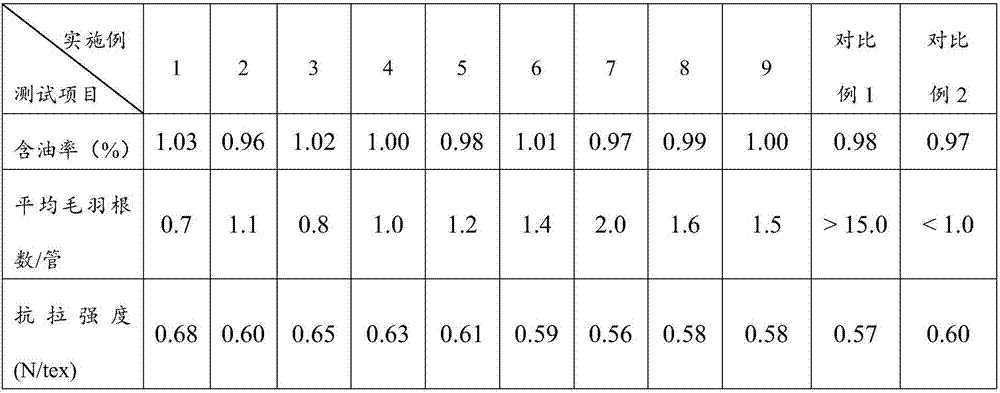

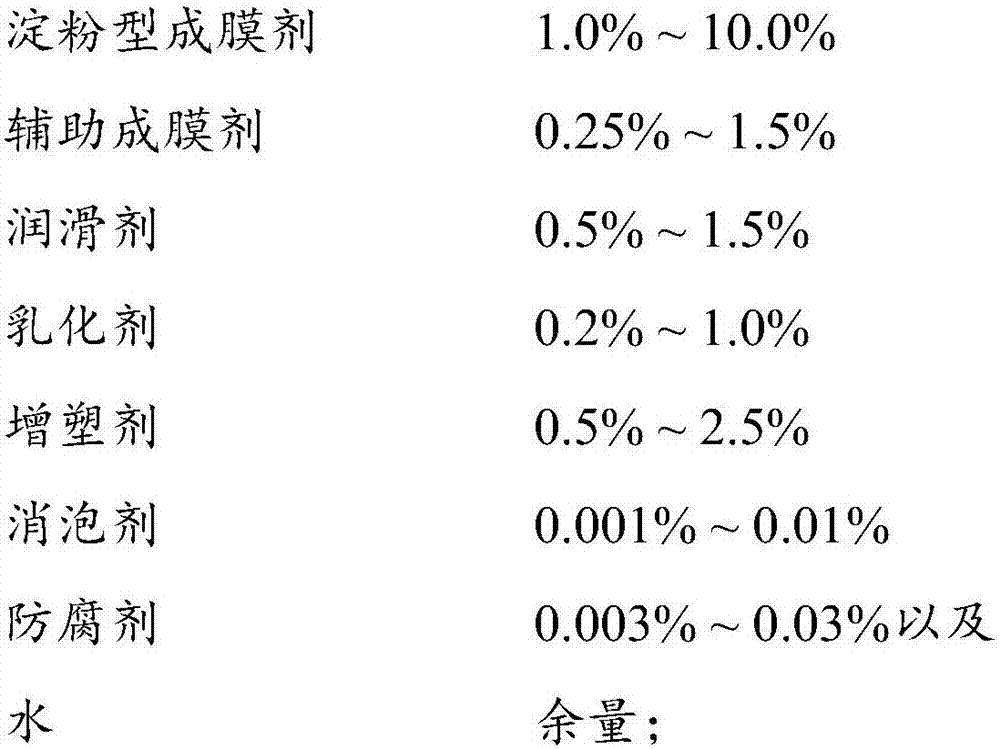

D450 electronic yarn impregnating agent and preparation method thereof

The invention relates to a D450 electronic yarn impregnating agent and a preparation method thereof. The D450 electronic yarn impregnating agent is prepared from, by mass, 1.0%-10.0% of starch-type film-forming agent, 0.25%-1.5% of auxiliary film-forming agent, 0.5%-1.5% of lubricant, 0.2%-1.0% emulsifier, 0.5%-2.5% of plasticizer, 0.001%-0.01% of defoamer, 0.003%-0.03% of preservative and the balance water. In the D450 electronic yarn manufacturing technology process, the D450 electronic yarn impregnating agent is coated to glass fiber to form an impregnating agent film, abrasion of glass fiber tows can be effectively reduced, hairiness is effectively reduced, meanwhile the D450 electronic yarn impregnating agent also has higher mechanical strength, and the surface properties of electronic base cloth are ensured.

Owner:广东志广生物科技有限公司

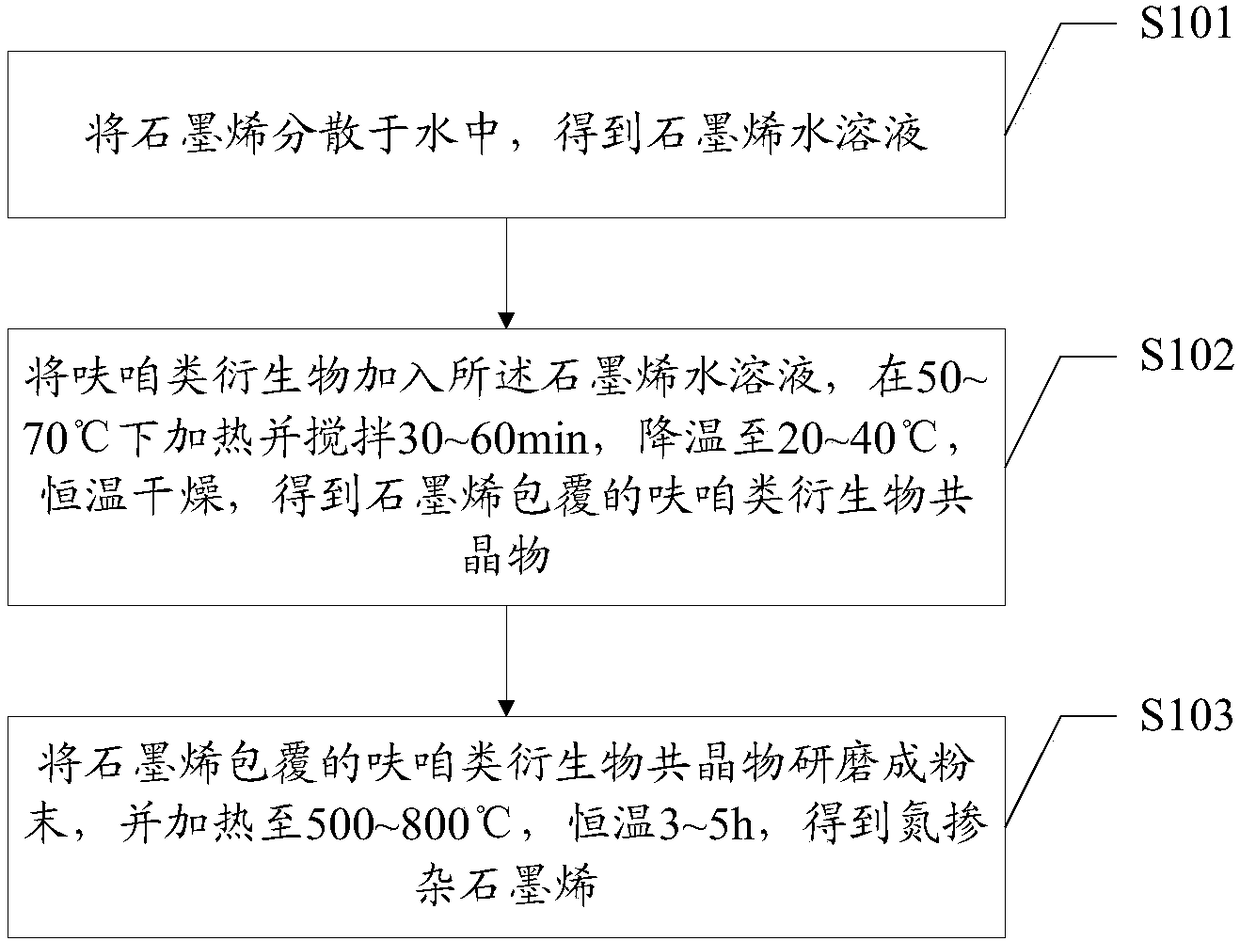

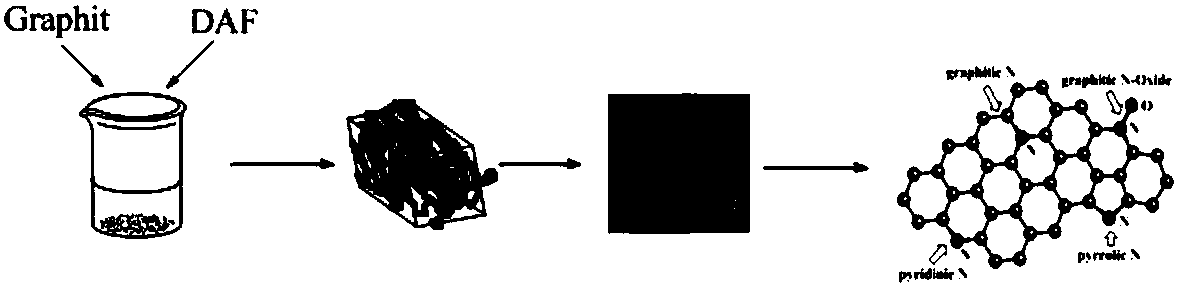

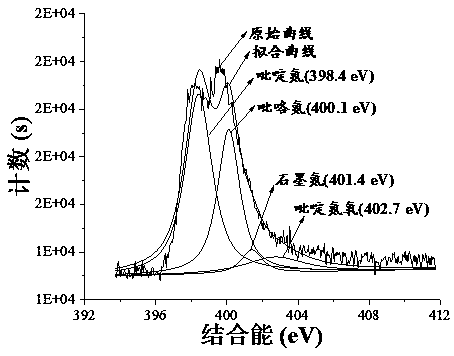

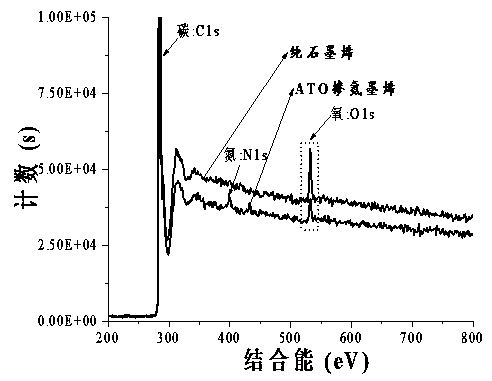

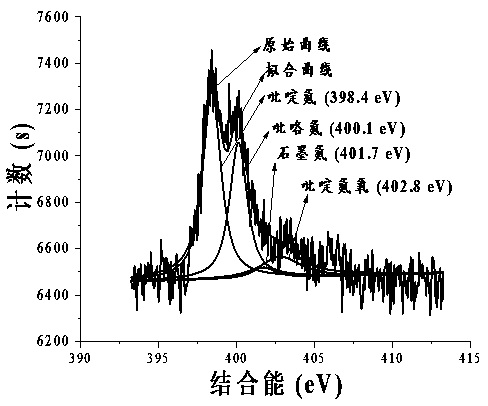

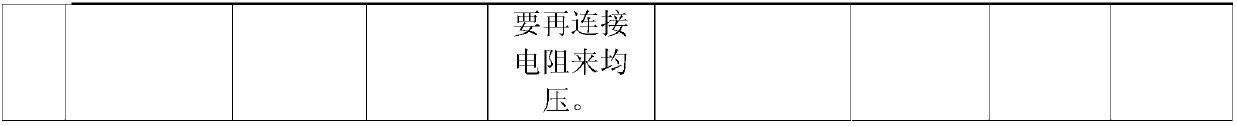

Method for preparing nitrogen-doped graphene from furazan derivatives as nitrogen source

The invention belongs to the technical field of material preparation, and particularly relates to a method for preparing nitrogen-doped graphene from furazan derivatives as a nitrogen source. The method comprises the following steps: dispersing graphene in water to obtain a graphene aqueous solution; adding the furazan derivatives to the graphene aqueous solution, performing heating and stirring at 50-70 DEG C for 30-60 min, performing cooling to 20-40 DEG C, and performing drying at constant temperature to obtain graphene-coated furazan derivative eutectic crystals; grinding the graphene-coated furazan derivative eutectic crystals into powder, and the powder is heated to 500-800 DEG C and kept at the constant temperature for 3-5 h to obtain nitrogen-doped graphene. Graphene in nitrogen-doped graphene uniformly coats the surface of the furazan derivative crystals without using additives such as adhesives and the like, and accordingly, surface performance of the furazan derivative crystals is completely maintained.

Owner:SHENZHEN UNIV

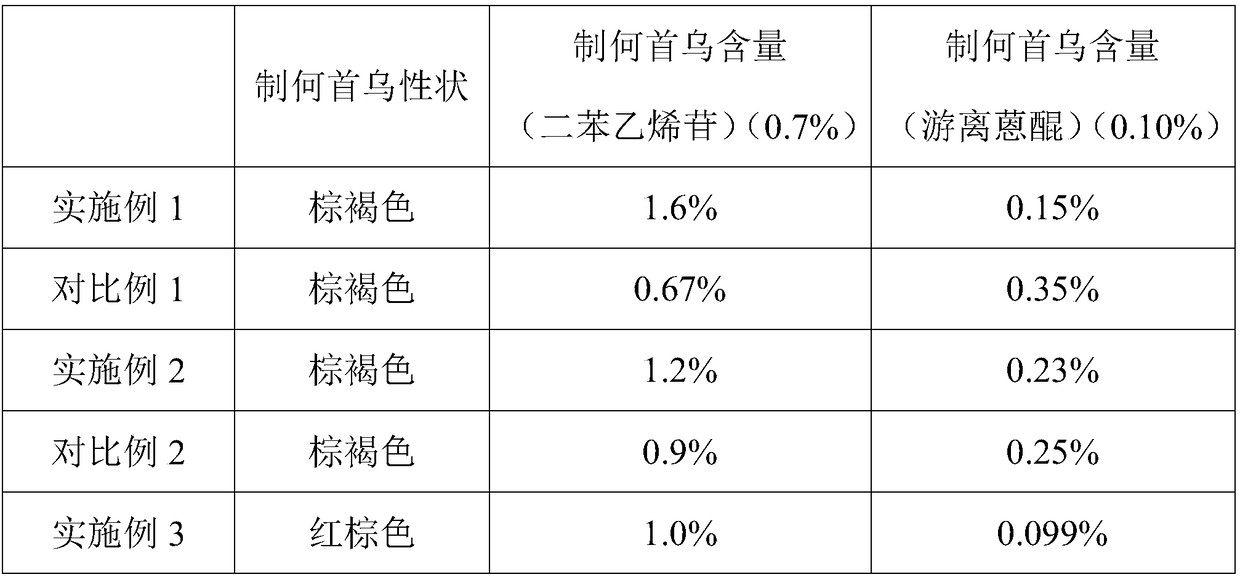

A processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product

InactiveCN109172648ASimple production processGuaranteed stabilityNervous disorderMetabolism disorderMedicinal herbsBULK ACTIVE INGREDIENT

The invention discloses a processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product . The processing method comprises the following steps: a washing step,a moistening step, a step of preparing black soybean juice, a step of steaming medicine and a step of baking medicine, namely, the radix Polygoni Multiflori decoction pieces are obtained. On the onehand, under the guidance of pharmacopoeia, the processing technology of Radix Polygoni Multiflori Preparata is optimized, and the best effect of wetting and swelling is obtained by the method of decompressing and moistening drugs, so as to ensure the content of active ingredients to meet the legal standard; on the other hand, the processing technology of radix Polygoni Multiflori is optimized. Product appearance and internal quality are improved, and the stability and reproducibility of varieties and processes are guaranteed.

Owner:KANGMEI PHARMA

Continuous extrusion forming mold for high-strength copper materials

InactiveCN105689426AGuaranteed Surface PropertiesImprove installation accuracyExtrusion diesTungstenHigh intensity

The invention discloses a continuous extrusion forming mold for high-strength copper materials. The continuous extrusion forming mold comprises an extrusion forming mold core; the extrusion forming mold core is produced by high-strength mold steel; and the high-strength mold steel consists of the following components in percentage by mass: 1.1% of nickel, 0.55% of carbon, 0.23% of silicon, 0.33% of manganese, 0.4% of chromium, 0.4% of tungsten, 0.03% of molybdenum, 0.06% of vanadium, 0.04% of cobalt, 0.004% of tellurium, 0.002% of neodymium, 0.002% of titanium, 0.006% of boron, and the balance of iron. In the continuous extrusion forming mold for the high-strength copper materials provided by the invention, the selected high-strength mold steel enables the surface of an extrusion forming channel to be not damaged so as to guarantee the surface performances of formed materials.

Owner:ANHUI XINXU NEW MATERIALS LTD BY SHARE LTD

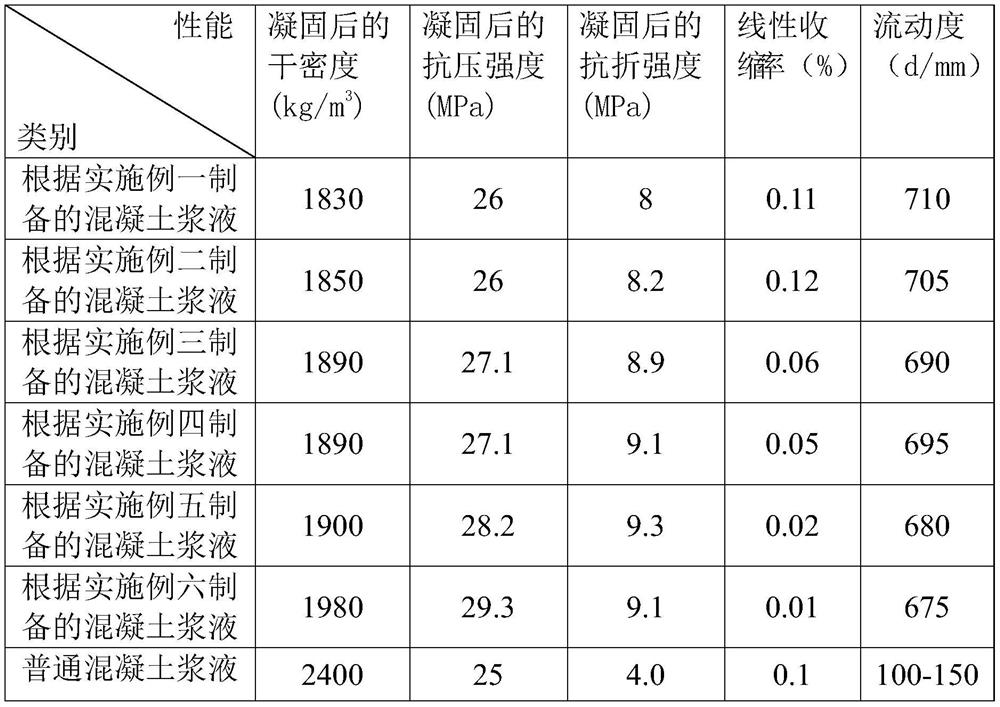

Lightweight high-strength concrete material with self-leveling characteristic and preparation and construction methods thereof

PendingCN114195454AImprove workability and liquidityImprove stabilityBuilding material handlingHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a lightweight high-strength concrete material with a self-leveling characteristic and a preparation and construction method thereof. Portland cement is used as a traditional cementing material, high belite cement and anhydrite are utilized, and hydroxypropyl methyl cellulose, an expanding agent, a water reducing agent, a stabilizer and the like are optimally proportioned, so that the workability and the flowability of concrete are greatly improved; meanwhile, the stability is improved, self-flowing leveling can be achieved under the influence of the gravity of materials, the effect is dense and flat after leveling, one-time forming is achieved, the phenomena of surface bubbles, yellow sand, voids, pitted surfaces and the like are avoided, the construction difficulty is lowered, the pouring time is shortened, and the working and economic efficiency is improved; damage and noise pollution caused by vibration of the heating pipe fitting or the embedded pipe fitting are avoided.

Owner:江苏华伟佳建材科技有限公司

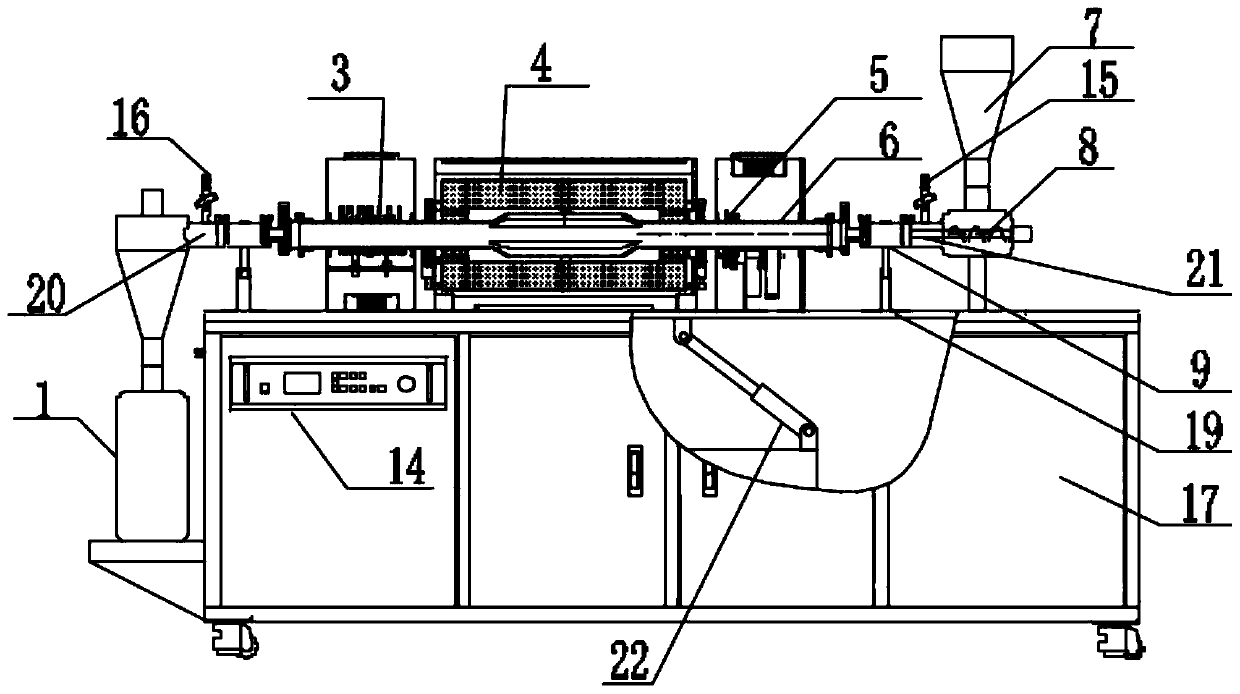

Continuous full-automatic control wrapping system for graphene powder

PendingCN109850876AReduce processing timeReduce power consumptionGrapheneSilicon carbideAutomatic controlElectrical control

The invention discloses a continuous full-automatic control wrapping system for graphene powder. The system comprises a wrapping mechanism, an operating platform, an independent electrical control cabinet and a stepped supporting plate; and one side of the operating platform is rotatably connected with the stepped supporting plate. According to the system provided by the invention, a screw feederis provided with a screw feeding rod extending to the inner wall of the thick end of a special-shaped quartz furnace tube, and the outer wall of the thin end, close to a collection tank, of the special-shaped quartz furnace tube is provided with a radio frequency coil, so that the above structure can shorten the preparation process time of the material; wrapping of the graphene powder is completedthrough heating and cooling of the radio frequency coil and the inclined wrapping mechanism; quartz baffles are welded in the special-shaped quartz furnace tube, polytetrafluoroethylene strips extending to the inner wall of the special-shaped quartz furnace tube and adhering to the quartz baffles are fixed at the inner wall of a pair of magnetofluids, in the process of collision of the polytetrafluoroethylene strips and the quartz baffles, the powder material is prevented from being agglomerated into a block, and therefore the surface properties of the powder material are effectively ensured.

Owner:ANHUI BEQ EQUIP TECH

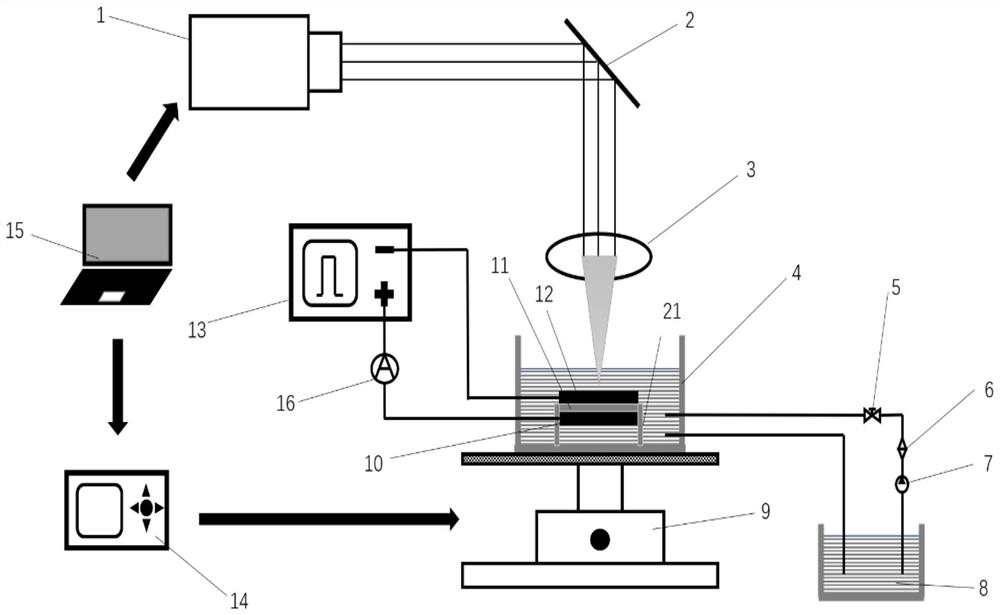

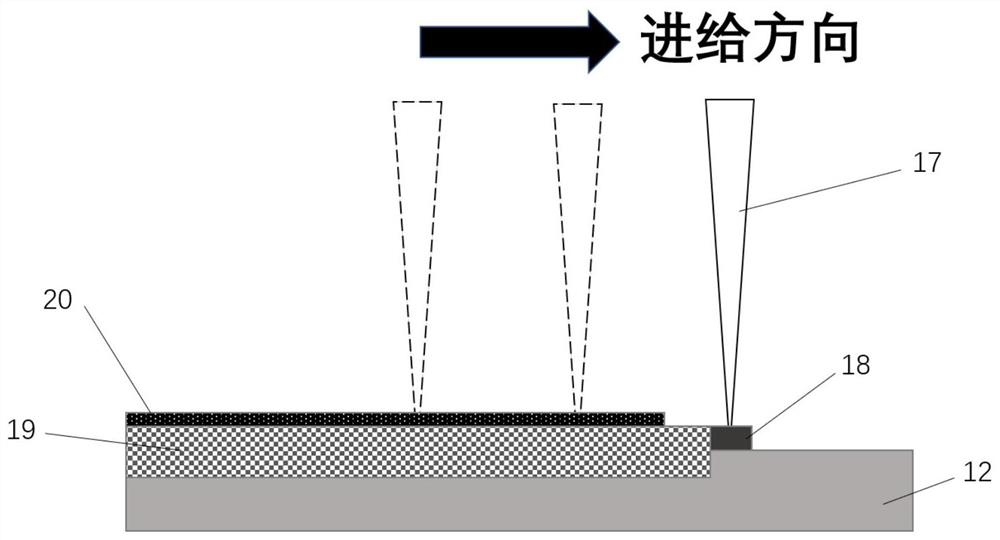

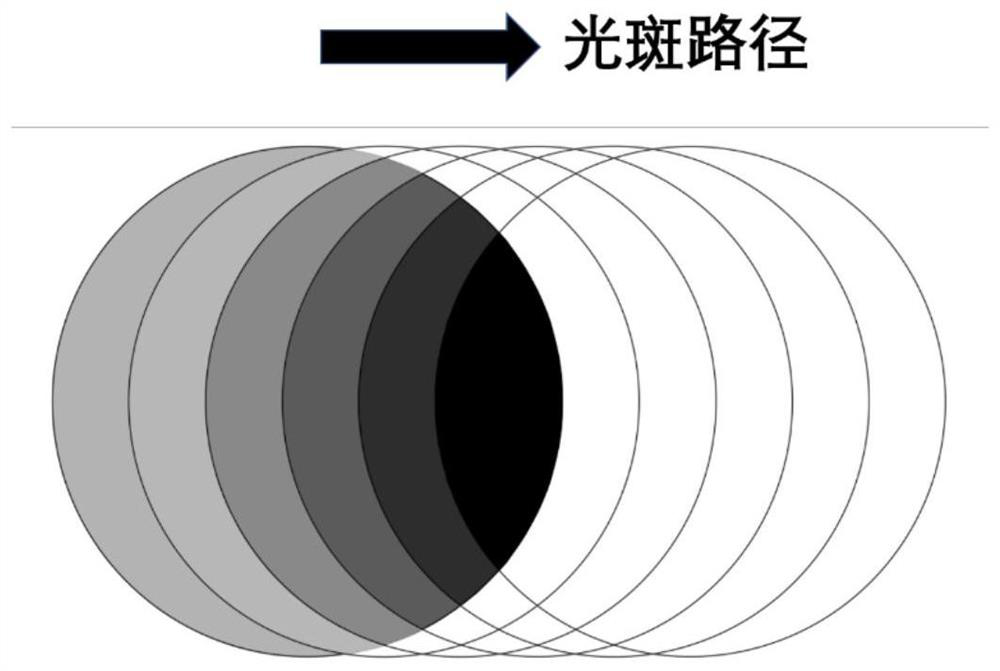

Method and device for preparing gradient plating layer through laser-assisted electro-deposition

ActiveCN113737237AImprove peeling phenomenonEliminate interfaceElectrolysis componentsElectrochemical responsePhysical chemistry

The invention discloses a method and device for preparing a gradient plating layer through laser-assisted electro-deposition. The method comprises the steps that electro-deposition of a deposition layer is performed on a workpiece substrate through pulse laser and electrochemical reaction, meanwhile, the deposition layer on the surface of the workpiece substrate is remelted through the heat of the pulse laser, a uniformly-distributed remelting layer is obtained, then residual heat is used for inducing electroplating, and the plating layer is obtained on the surface of the remelting layer. According to the method, a three-layer gradient structure of base material-remelting layer-plating layer can be synchronously prepared, an interface between a plating layer material and a base material is eliminated, combination of the plating layer and a base body is facilitated, the plating layer stripping phenomenon is improved, and meanwhile, the surface performance of the workpiece substrate can be guaranteed. In addition, the device can realize relative movement between the laser beam and the workpiece substrate, so that instantaneous remelting can be initiated on the surface of the workpiece by the aid of the heat accumulation effect of multiple pulse laser beams.

Owner:JIANGSU UNIV

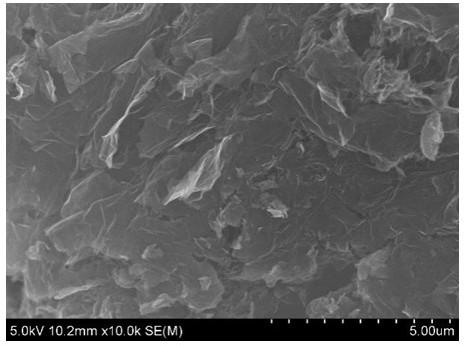

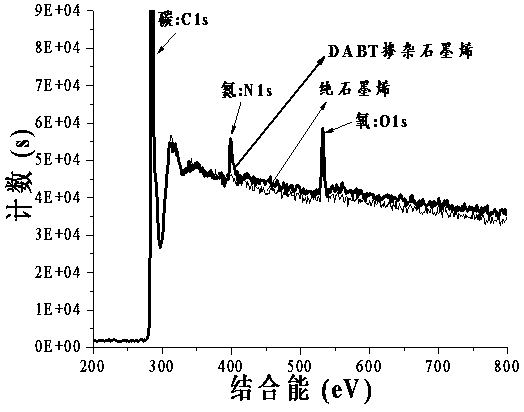

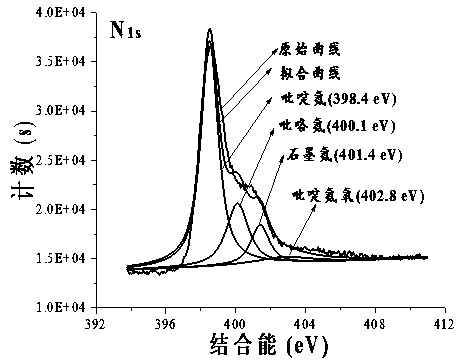

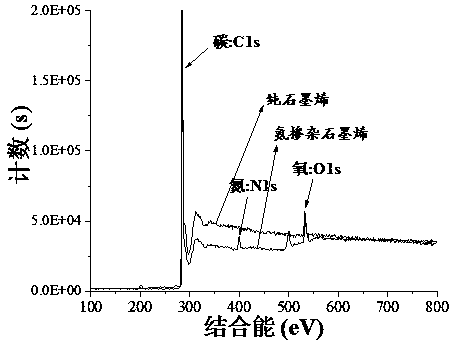

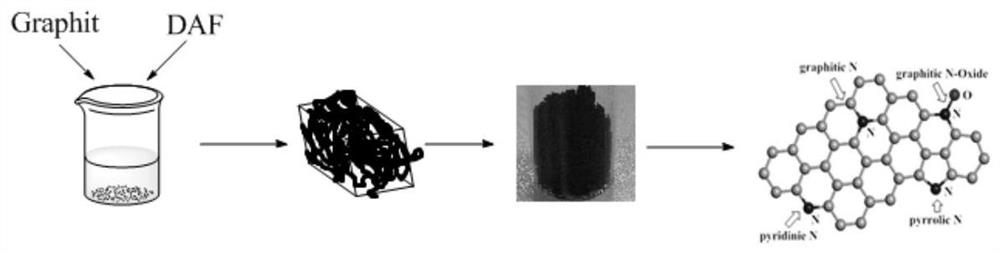

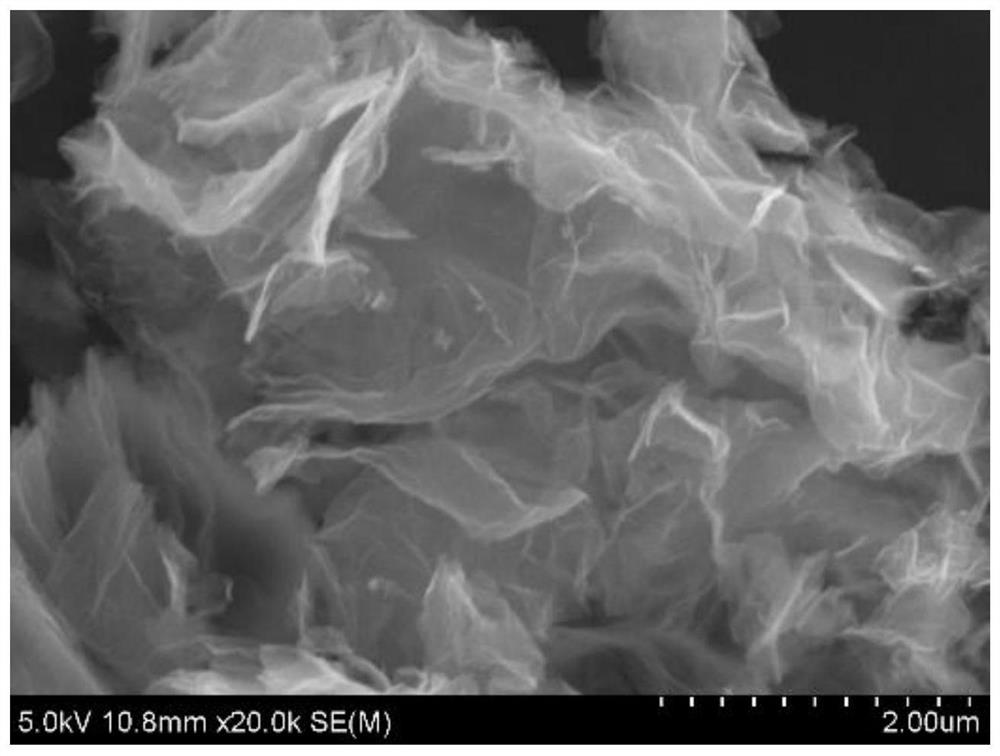

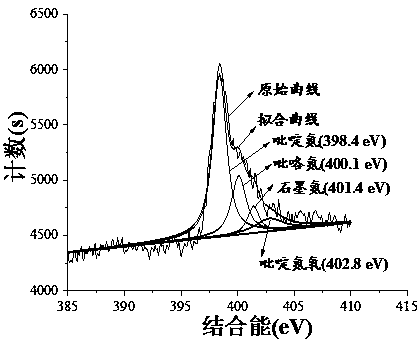

Preparation method of nitrogen-doped graphene material based on 5, 5'-diamino-3, 3'-1, 2, 4-triazole

The invention discloses a preparation method of a nitrogen-doped graphene material based on 5, 5'-diamino-3, 3'-1, 2, 4-triazole. The method comprises the following steps: dispersing graphene into N,N '-dimethylformamide, adding an N, N'-dimethylformamide solution of 5, 5 '-diamino-3, 3'-1, 2, 4-triazole, heating at 50-100 DEG C for 30-60 minutes, cooling to 0-4 DEG C, and drying to obtain a graphene-coated 5, 5 '-diamino-3, 3'-1, 2, 4-triazole eutectic; grinding 5, 5 '-diamino-3, 3'-1, 2, 4-triazole eutectic into powder, and heating the powder at 500-800 DEG C for 3-5 hours to obtain a nitrogen-doped graphene material; according to the preparation method, the graphene is uniformly coated on the surface of the 5, 5 '-diamino-3, 3'-1, 2, 4-triazole crystal, and additives such as an adhesive are not needed, so that the surface performance of the 5, 5 '-diamino-3, 3'-1, 2, 4-triazole crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

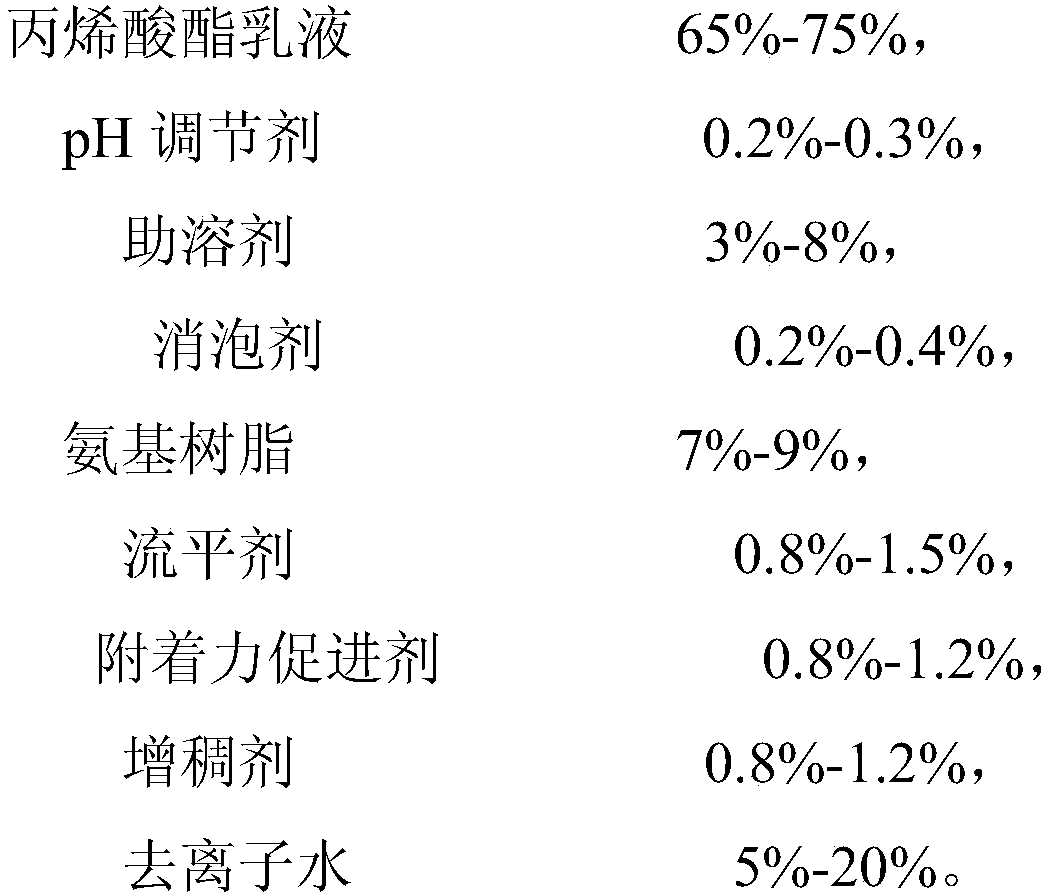

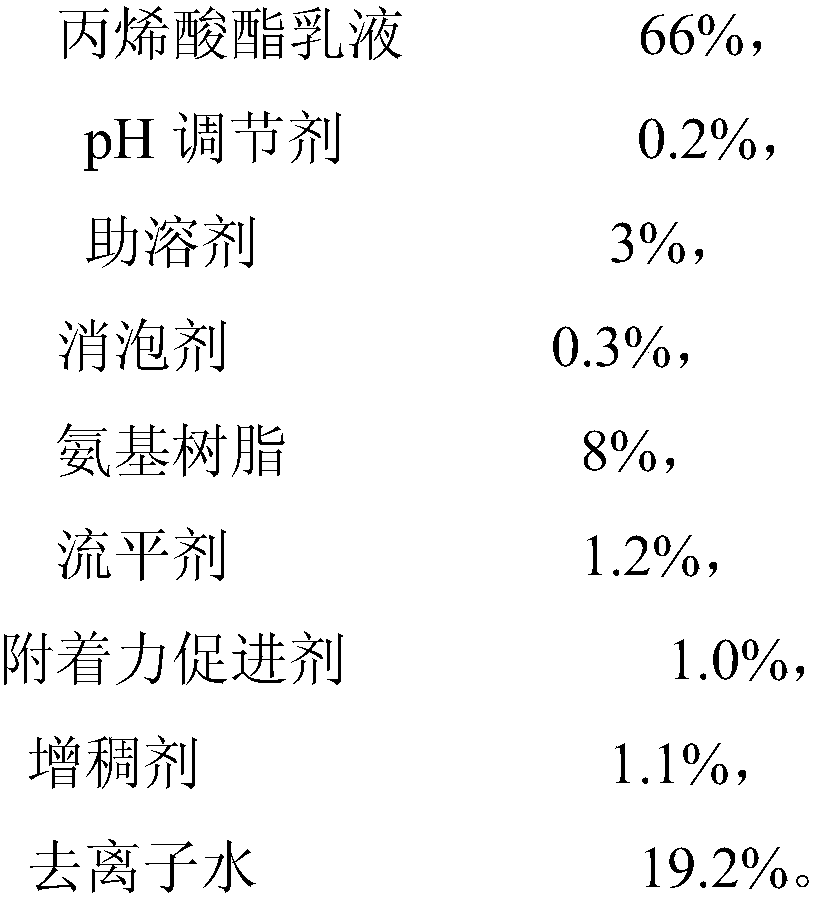

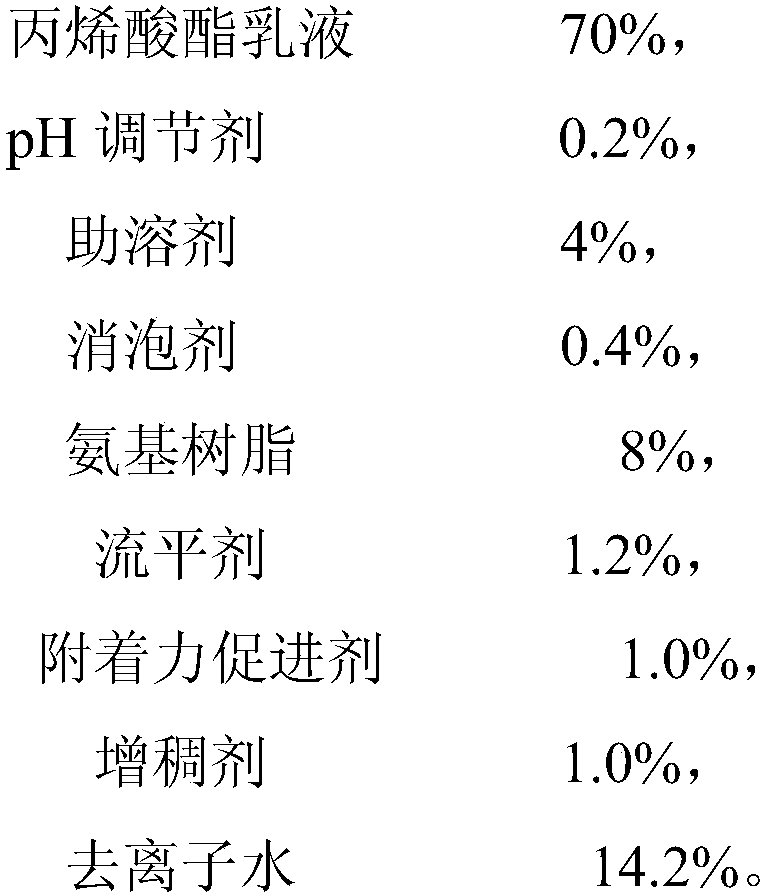

Waterborne emulsion type glazing golden varnish special for bicycles and preparation method thereof

The invention discloses a waterborne emulsion type glazing golden varnish special for bicycles and a preparation method thereof. The invention relates to the waterborne emulsion type glazing golden varnish special for the bicycles. The waterborne emulsion type glazing golden varnish special for the bicycles comprises the following components by the mass percentage: 65%-75% of an acrylate emulsion,0.2%-0.3% of a pH regulator, 3%-8% of a cosolvent, 0.2%-0.4% of a defoamer, 7%-9% of amino resin, 0.8%-1.5% of a leveling agent, 0.8%-1.2% of an adhesive force promoter, 0.8%-1.2% of a thickener, and5%-20% of deionized water. The waterborne emulsion type glazing golden varnish special for the bicycles has the advantages of low VOC, high weather resistance, abrasion resistance, high gloss, good decorative effect, and easy construction, and can be applied to bicycles, electric bicycles and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

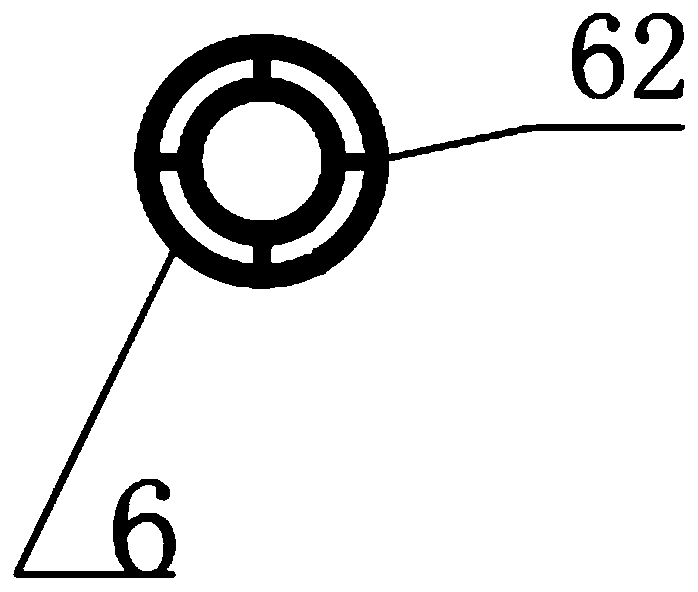

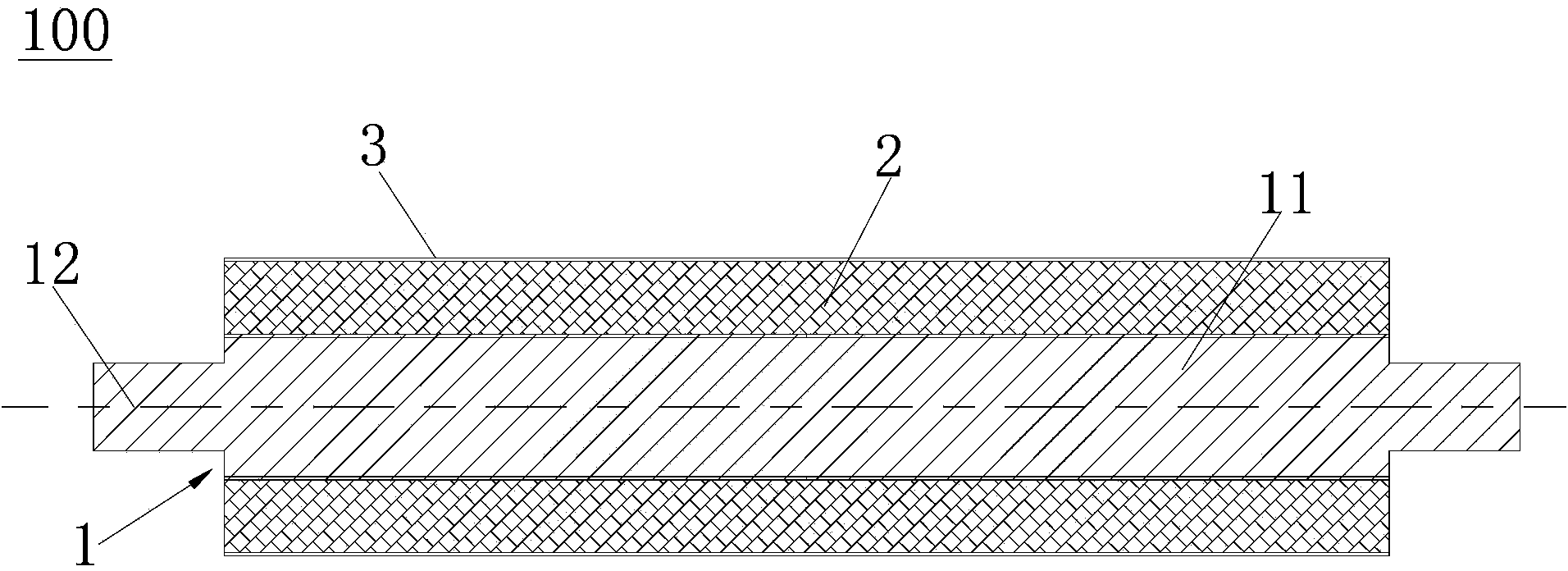

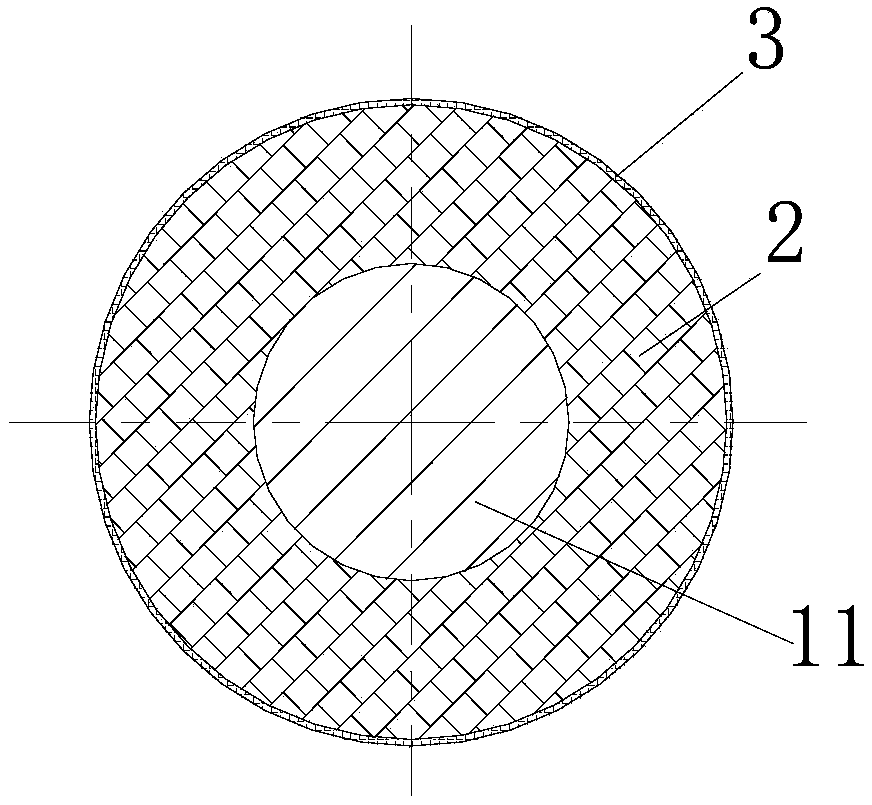

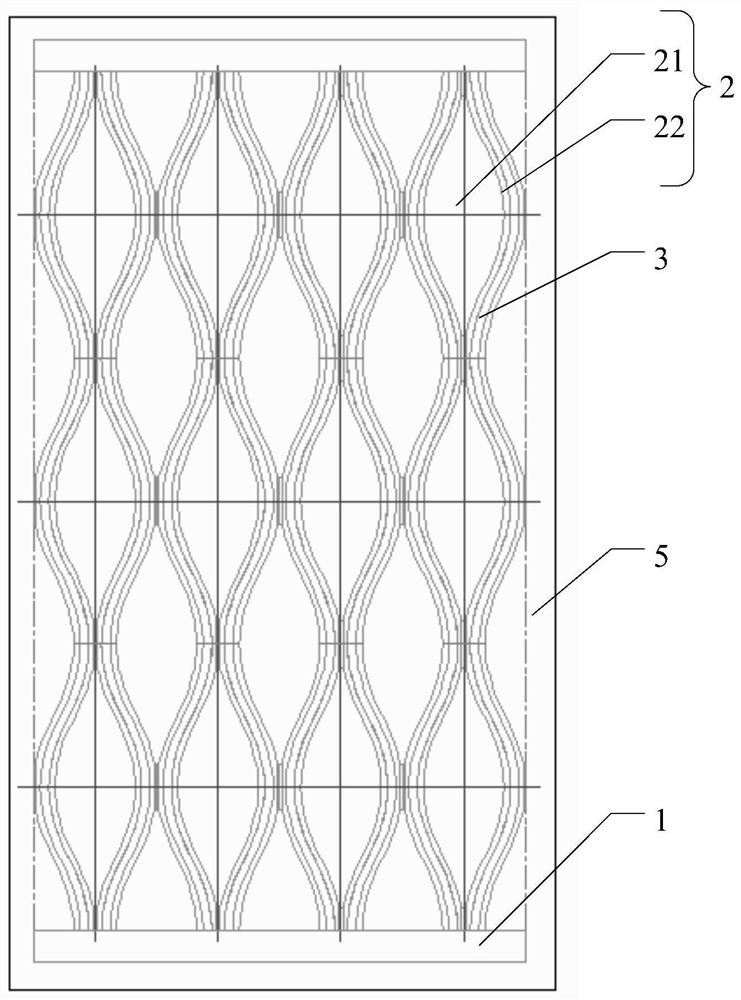

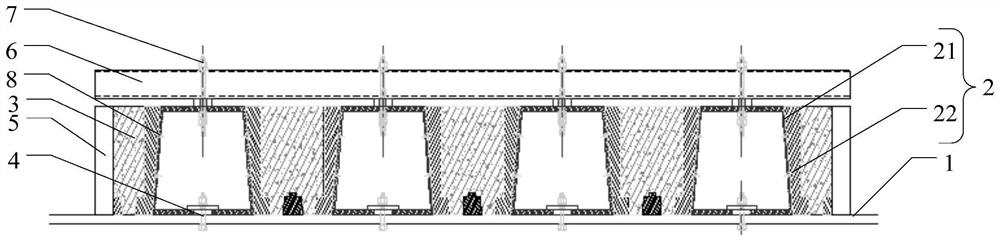

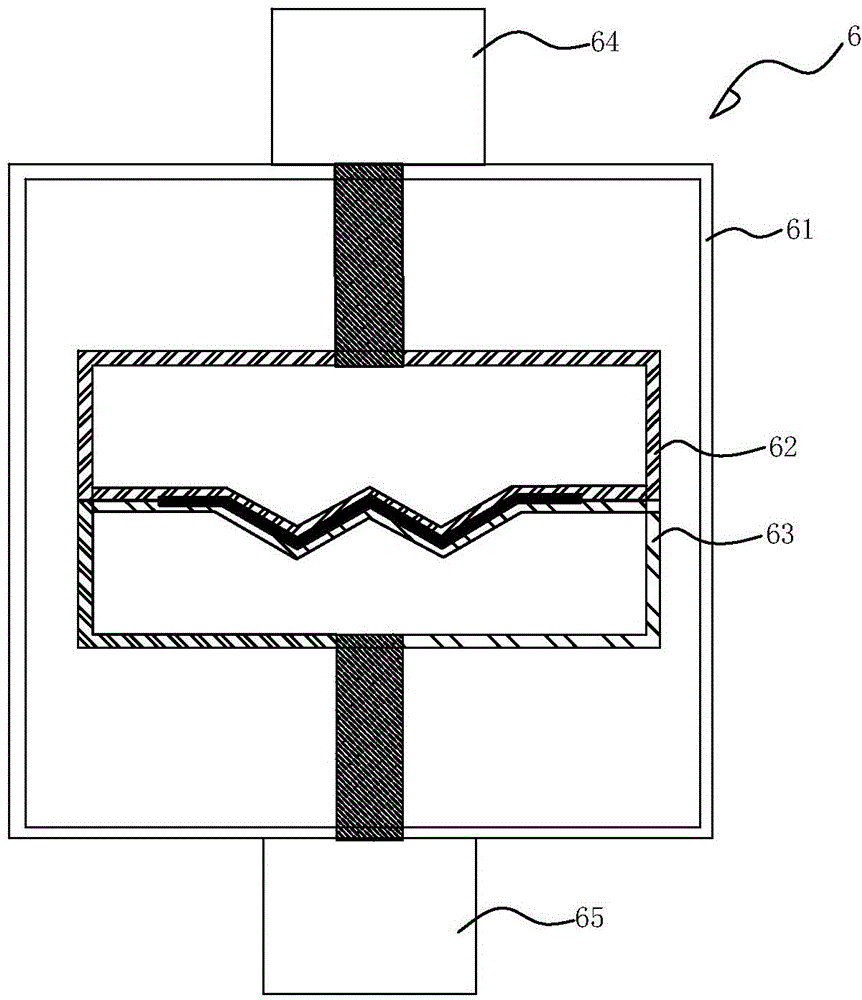

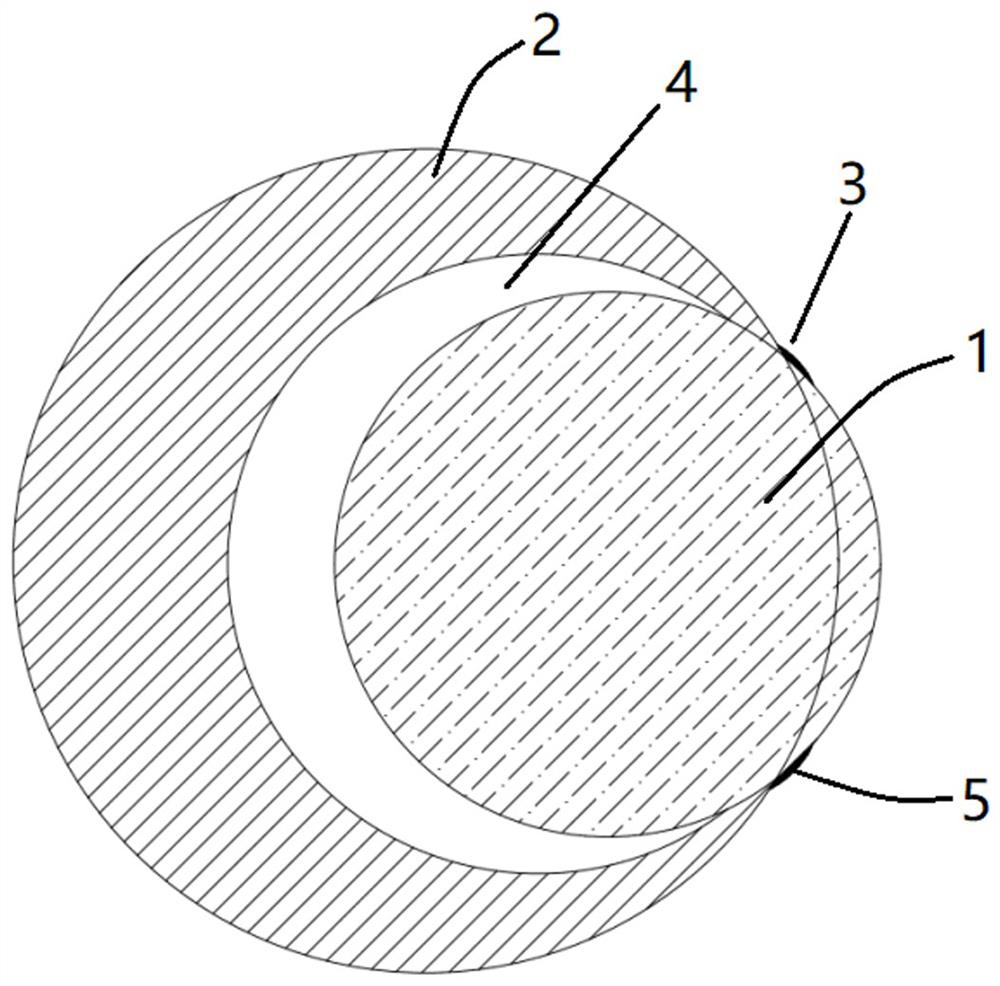

Composite material laying compression roller with laminating-type rubber covered roller structure

The invention provides a composite material laying compression roller with a laminating-type rubber covered roller structure. The composite material laying compression roller is provided with a metal mandrel which comprises a cylindrical mandrel body part as well as two bearing support parts correspondingly arranged at two ends of the mandrel body part; the bearing support parts and the mandrel body part are coaxially arranged, and the outer diameters of the bearing support parts are less than the outer diameter of the mandrel body part; the outer side surface of the mandrel body part is coated with an elastic rubber layer; the outer side of the elastic rubber layer is coated with a roller surface rubber layer. The composite material laying compression roller with the laminating-type rubber covered roller structure is convenient to process and manufacture and low in production cost, has long service life and favorable maintainability, and overcomes defects of the prior art.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Preparation method of nitrogen-doped graphene material containing 3, 5-diamino-1H-1, 2, 4-triazole

The invention discloses a preparation method of a nitrogen-doped graphene material containing 3, 5-diamino-1H-1, 2, 4-triazole. The method comprises the following steps: dispersing graphene in deionized water, adding a 3, 5-diamino-1H-1, 2, 4-triazole ethanol solution into the graphene solution, heating the solution at 50-100 DEG C for 30-60 minutes, cooling the solution to 0-4 DEG C, drying the solution to obtain a graphene-coated 3, 5-diamino-1H-1, 2, 4-triazole eutectic material, grinding the 3, 5-diamino-1H-1, 2, 4-triazole eutectic material into powder, and heating the powder at 500-800 DEG C for 3-5 hours to obtain a nitrogen-doped graphene material. According to the preparation method disclosed by the invention, 3, 5-diamino-1H-1, 2, 4-triazole is utilized to react with graphene, sothat the graphene material with relatively high nitrogen doping content is obtained. According to the material, the graphene uniformly coats the surface of the 3, 5-diamino-1H-1, 2, 4-triazole crystal, and additives such as an adhesive and the like are not needed, so that the surface performance of the 3, 5-diamino-1H-1, 2, 4-triazole crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Continuous fiber reinforced thermosetting flame-retardant prepreg and preparation method thereof

The invention discloses a continuous fiber reinforced thermosetting flame-retardant prepreg and a preparation method thereof. The continuous fiber reinforced thermosetting flame-retardant prepreg comprises a prepreg resin and a continuous fiber fabric, and is prepared by an environment-friendly hot melting process, wherein the content of the prepreg resin in the flame-retardant prepreg is 38-45%, the prepreg resin is prepared from the following raw materials: an epoxy resin, a flame retardant, an auxiliary additive, a leveling additive, a coloring agent, a curing agent and an accelerant, the accelerant comprise a first accelerant and a second accelerant, the first accelerant is one or more of organic urea, thiourea or imidazole compounds, the second accelerant is complexed aromatic diamine, and the flame-retardant prepreg can realize a rapid hot-in and hot-out process at a high temperature of 140-160 DEG C, does not influence the mechanical properties of the molded material, can be rapidly cured and molded for 3-6 minutes, has excellent flame retardant property, can achieve the UL94V0 flame retardant level, and further can achieve spraying-free so as to eliminate the traditional grinding and spraying technological process.

Owner:HENGSHEN

Forming mold and construction method for prefabricated hollowed-out concrete member

InactiveCN113059661ASolve difficult demouldingSolve problems such as component breakageMouldsMould fastening meansPre stressConstruction engineering

The invention provides a forming mold for a prefabricated hollowed-out concrete member. The forming mold comprises a working platform and a forming structure located on the working platform, wherein the forming structure comprises a plurality of modules, each module comprises an inner core column, the side face of each inner core column is wrapped with an outer mold wrapping layer, and the adjacent modules are spaced to form prefabricated concrete pouring cavities. The invention further provides a construction method for the prefabricated hollowed-out concrete member. According to the forming mold and the construction method for the prefabricated hollowed-out concrete member, the problems that an existing mold for preparing an oversized hollowed-out concrete member is extremely difficult to demold or the member is fractured due to the conditions of complex rib distribution, non-prestress and the like formed by a curved hollowed-out shape of the member can be solved, and the prepared concrete member is high in dimensional precision and low in manufacturing cost.

Owner:上海鼎中新材料有限公司

Preparation method of nitrogen-doped graphene material based on 4-amino-1,2,4-triazole-5-one

InactiveCN111017917AGuaranteed Surface PropertiesChange structureCarbon compoundsDoped grapheneAdhesive

The invention discloses a preparation method of a nitrogen-doped graphene material based on 4-amino-1,2,4-triazole-5-one. The method comprises the steps: dispersing graphene into deionized water; adding a 4-amino-1,2,4-triazole-5-one aqueous solution, heating for 30-60 min at the temperature of 50-100 DEG C, cooling to room temperature, and drying to obtain a graphene-coated 4-amino-1,2,4-triazole-5-one eutectic material; and grinding into powder, and heating for 1.5-6 h in a tubular furnace at the temperature of 500-800 DEG C to obtain the nitrogen-doped graphene material. The surface of the4-amino-1,2,4-triazole-5-one crystal is uniformly coated with graphene in the material obtained by the preparation method disclosed by the invention, and additives such as an adhesive and the like arenot needed, so that the surface performance of the 4-amino-1,2,4-triazole-5-one crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Process for removing nonmetal inclusion in molten steel

InactiveCN101307374BReduce the number of inclusionsInclusion size is smallProcess efficiency improvementNon-metallic inclusionsMolten steel

Owner:BAOSHAN IRON & STEEL CO LTD

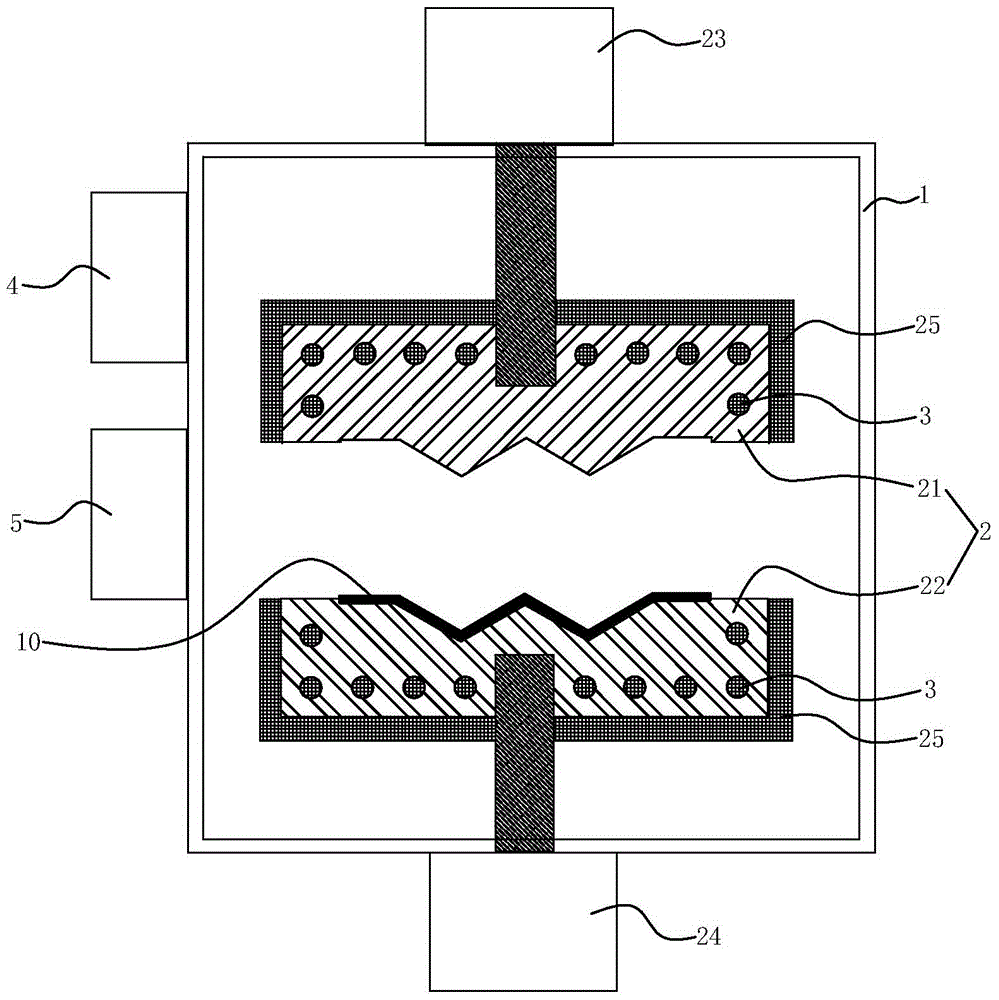

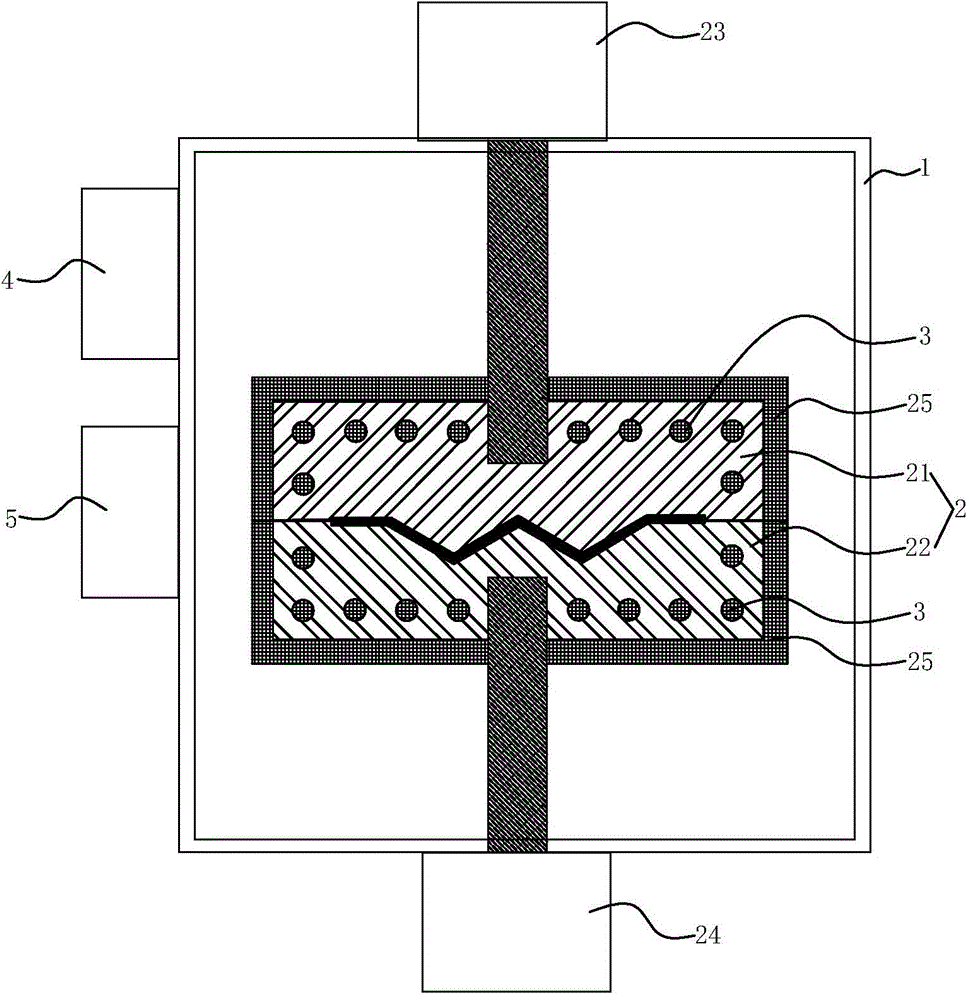

Online pressure metal thermal treatment process and online pressure metal thermal treatment device

The invention discloses an online pressure metal thermal treatment process and an online pressure metal thermal treatment device. According to the process, a pressure device is adopted to synchronously heat a workpiece and apply a pressure to the workpiece so as to realize thermal treatment and then discharging and cooling are automatically carried out. The metal thermal treatment device comprises a supporting body, a pressure mechanism, two heating mechanisms, a temperature control device, a time control device and a cooling mechanism, wherein the pressure mechanism comprises first and second pressure bases which are mounted in the supporting body and can be propped against each other and first and second driving mechanisms; first and second profiled grooves are respectively formed in the opposite surfaces of the first and second pressure bases; insulation structures are also arranged on the outer surfaces of the first and second pressure bases; the two heating mechanisms are respectively mounted in the first and second pressure bases; the temperature control accuracy of the temperature control device is 1 DEG C; the temperature control device is mounted outside the supporting body; the time control accuracy of the time control device is 1s; the time control device is mounted outside the supporting body; the cooling mechanism is mounted below the supporting body. According to the online pressure metal thermal treatment process and the online pressure metal thermal treatment device, the fact that the workpiece has qualified performance in the treatment process is guaranteed, and the phenomena of deformation, blowing-out discharging and the like are avoided.

Owner:TWD METAL PRODN

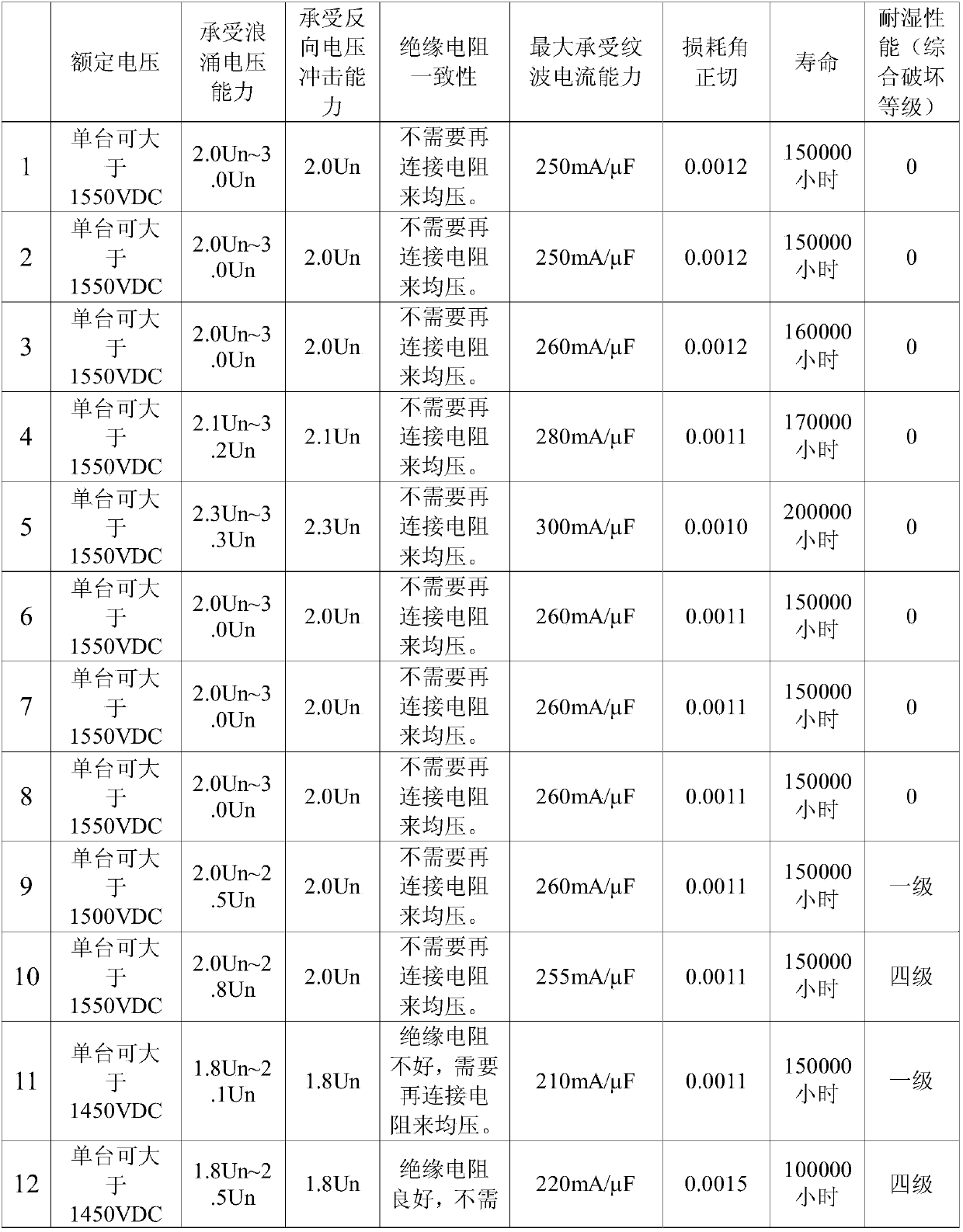

Evaporation process of a metallized polypropylene film dielectric capacitor

InactiveCN105869890BImprove surface conditionHigh surface energyThin/thick film capacitorStacked capacitorsDielectricPolymer science

The invention discloses an evaporation technology of a metallized polypropylene film dielectric capacitor. The technology comprises steps as follows: 1) surface treatment of a polypropylene film layer; 2) pretreatment of an evaporation material; 3) evaporation. An evaporation layer of a metallized polypropylene film dielectric capacitor obtained with the evaporation technology is firmly combined with a base material and has the excellent surface performance, and the obtained metallized polypropylene film dielectric capacitor is high in self-healing property and has the very high wet resistance.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

A preparation method of nitrogen-doped graphene with furoxan derivatives as nitrogen source

The invention belongs to the technical field of material preparation, and in particular relates to a method for preparing nitrogen-doped graphene with furoxan derivatives as a nitrogen source. The method comprises: dispersing graphene in water to obtain a graphene aqueous solution; adding furoxan derivatives to the graphene aqueous solution, heating and stirring at 50-70°C for 30-60min, cooling to 20-40°C, and constant temperature Drying to obtain graphene-coated furoxan derivative eutectics; grinding the graphene-coated furoxan derivative eutectics into powder, and heating to 500-800°C, constant temperature for 3-5h, to obtain nitrogen doped graphene. In the nitrogen-doped graphene, the graphene is uniformly coated on the surface of the furoxan derivative crystal, without using additives such as adhesives, and completely maintains the surface properties of the furoxan derivative crystal.

Owner:SHENZHEN UNIV

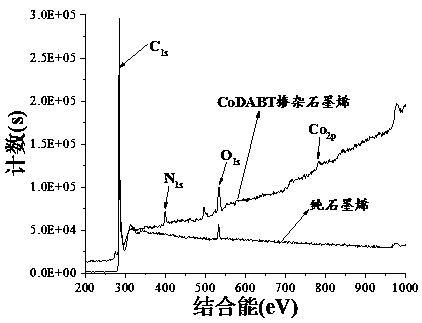

Method for preparing graphene material based on 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt

InactiveCN110980713AGuaranteed Surface PropertiesChange structureCarbon compoundsDoped grapheneCobalt salt

A method for preparing a graphene material based on 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt is disclosed. The method includes dispersing graphene into deionized water; adding an aqueous solutionof the 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt; heating at 50-100 DEG C for 30-60 min; cooling to 0-4 DEG C; drying to obtain a 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt eutectic substance coated with graphene; grinding the substance into powder; and heating the powder in a tubular furnace at 500-800 DEG C for 3-5 h to obtain the nitrogen--cobalt co-doped graphene material. In the obtainedmaterial, 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt crystals are evenly coated with the graphene, and surface performance of the 5,5'-diamino-3,3'-1,2,4-triazole cobalt salt crystals can be completely maintained without the use of an adhesive or other auxiliary agents.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Woven bag internally covering film

ActiveCN103524864BLess investmentSmall footprintSynthetic resin layered productsEngineeringSmooth surface

The invention discloses a woven bag internally covering film. The internally covering film comprises the components by the weight percentage: 75%-85% of EVA 14-2; 15%-10% of LLDPE 18; 6%-3% of HDPE 9455; and 4%-2% of linear 7042 or 7047. The woven bag internally covering film can be directly internally adhered to woven cloth, replaces an internally covering film having a layer structure; and the woven bag internally covering film has smooth surface, has strong adhesion ability on the woven cloth, and reduces the manufacturing cost of a woven bag with the internally covering film.

Owner:开原市升达塑料彩印厂

High temperature-resistant ultralow temperature-cured epoxy polyester powdery coating

InactiveCN103275597BReasonable formulaLow curing temperaturePowdery paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses a high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating solves the problem that the existing low temperature-cured epoxy polyester powdery coating has poor heat resistance and poor thermal conductivity so that in curing, temperatures in a coating film prepared from the existing low temperature-cured epoxy polyester powdery coating are not different and coating curing rates are not different and thus the coating film produces orange peel phenomenon and even crazes and coating film surface-effects are influenced. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating is prepared from 30 to 40wt% of epoxy resin, 15 to 20wt% of polyester resin, 0.5 to 1.5wt% of polyarylene sulfide resin, 10 to 15wt% of titanium dioxide, 2 to 5wt% of nano-metal powder subjected to surface treatment, 0.5 to 1wt% of dibutyltin dilaurate, 1 to 3wt% of an assistant, 1 to 5wt% of sodium fluoride, 15 to 20wt% of a filling material and 10 to 15wt% of a pigment. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating has a low curing temperature, good heat resistance, and physical and mechanical properties and chemical resistance satisfying industrial requirements.

Owner:HANGZHOU GOLDEAGLE PLASTIC POWDER

Nylon carbon fiber and preparation process thereof

PendingCN113862825AImprove high temperature resistanceImprove friction resistanceFibre typesConjugated synthetic polymer artificial filamentsNylon materialMetal coating

The invention provides a nylon carbon fiber. The nylon carbon fiber comprises a core layer and a skin layer, and is prepared by composite spinning of the core layer made of a nylon material and the skin layer made of a carbon black material through a composite spinning assembly; the core layer deviates from the circle center of the skin layer and is not completely wrapped in the skin layer; a concave transition area is formed in the adjacent connection position of the core layer and the skin layer, and the core layer area of the transition area is in a sticky state through physicochemical treatment and is coated with a metal coating; and the nylon carbon fiber forms anisotropic manifestation on the periphery of the cross section by taking the geometric center as the center. The nylon carbon fiber disclosed by the invention has excellent electrical conductivity and anisotropy, has dual characteristics of nylon and carbon fiber, also has the advantages of metal fiber, is convenient for later manufacturing and treatment, and has application prospects in various fields.

Owner:常隆塑胶科技(苏州)有限公司

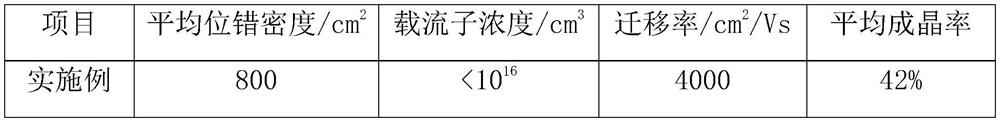

Preparation method of indium phosphide seed crystal

PendingCN114161590AGuaranteed performanceGuaranteed internal performancePolycrystalline material growthAfter-treatment detailsSemiconductor materialsCrystal orientation

The invention discloses a preparation method of indium phosphide seed crystals, and relates to the technical field of semiconductor materials. According to the preparation method of the indium phosphide seed crystal, the angle of an indium phosphide single crystal is adjusted, and after a qualified area is obtained through testing, the indium phosphide seed crystal is obtained through drilling, grinding and polishing. The invention discloses a preparation method of an indium phosphide seed crystal, the indium phosphide seed crystal can be rapidly prepared, the operation process is simple and rapid and is not influenced by the crystal shape and the crystal orientation angle, the treated seed crystal is smooth and flat in surface and stable in property, and the crystal growth quality of an indium phosphide single crystal is greatly improved.

Owner:威科赛乐微电子股份有限公司

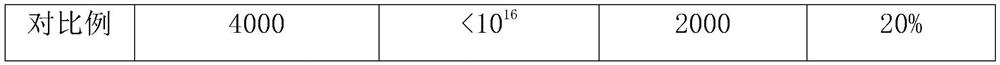

Water-based paint for wine bottle cap and preparation method thereof

InactiveCN111073472AGood wettabilityGood flexibility and processabilityEpoxy resin coatingsPolyester coatingsEcologyDefoaming Agents

The invention discloses a water-based paint for a wine bottle cap. The water-based paint is characterized by comprising the following components in percentage by weight: 40-45% of water-based polyester resin, 6-10% of a water-based cross-linking agent, 0.2-0.4% of a water-based defoamer, 0.2-0.3% of a water-based leveling agent, 0.4-0.8% of a water-based wetting agent, 1-3% of a PH value neutralizer, 1-3% of a water-based adhesive agent, 3-5% of water-based epoxy resin, 25-30% of rutile titanium dioxide and 8-15% of purified water. The water-based paint has the advantages of reducing atmospheric pollution, being rich in environmental protection and being suitable for wine bottle caps; the invention also discloses a preparation method of the water-based paint, and the water-based is easy toimplement.

Owner:佛山市沃特布恩新型材料有限公司

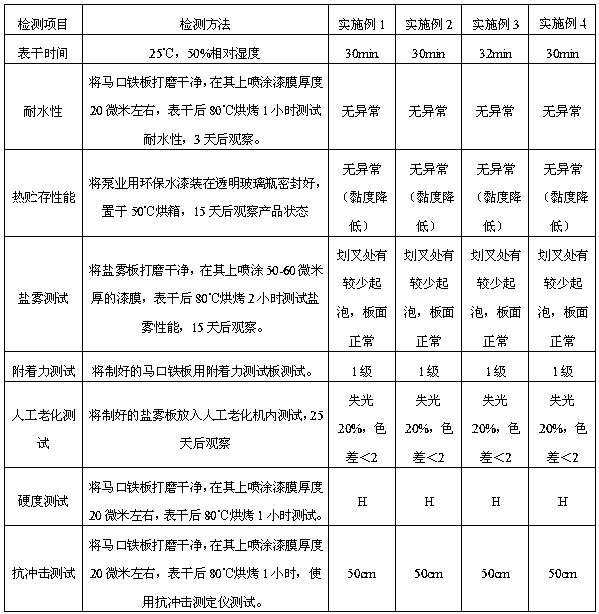

A kind of environmental protection water paint for pump industry and preparation method thereof

ActiveCN106893458BImprove environmental friendlinessInviolableAnti-corrosive paintsPolyester coatingsPolyesterMaterials science

The invention discloses an environment-friendly water paint used in pump industry and a preparation method thereof and relates to the technical field of anticorrosive coatings. The environment-friendly water paint is prepared from, by weight, waterborne resin comprising 15-25% of polyester polyol, assistants comprising 0.12-0.35% of film forming additive, 0.9-2.1% of neutralizer, 0.18-1.5% of defoamer, 0.15-0.38% of dispersant, 30-37% of ionic water, 0.1-0.35% of wetting agent and 0.75-1.67% of drier, packing comprising 0.31-0.67% of carbon black, 5-12% of iron oxide black, 5-8.8% of 808 anti-rust material, 2.5-5.3% of compound zinc phosphate, 5.5-8.8% of compound ferrotitanium powder, 7-11.6% of barium sulfate and 1-3.3% of talcum powder, 4.3-7.8% of anti-sinking thixotropic agent. The paint has good environmental friendliness and meets the national standard requirements in the aspects of corrosion, rusting and impact resistance and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

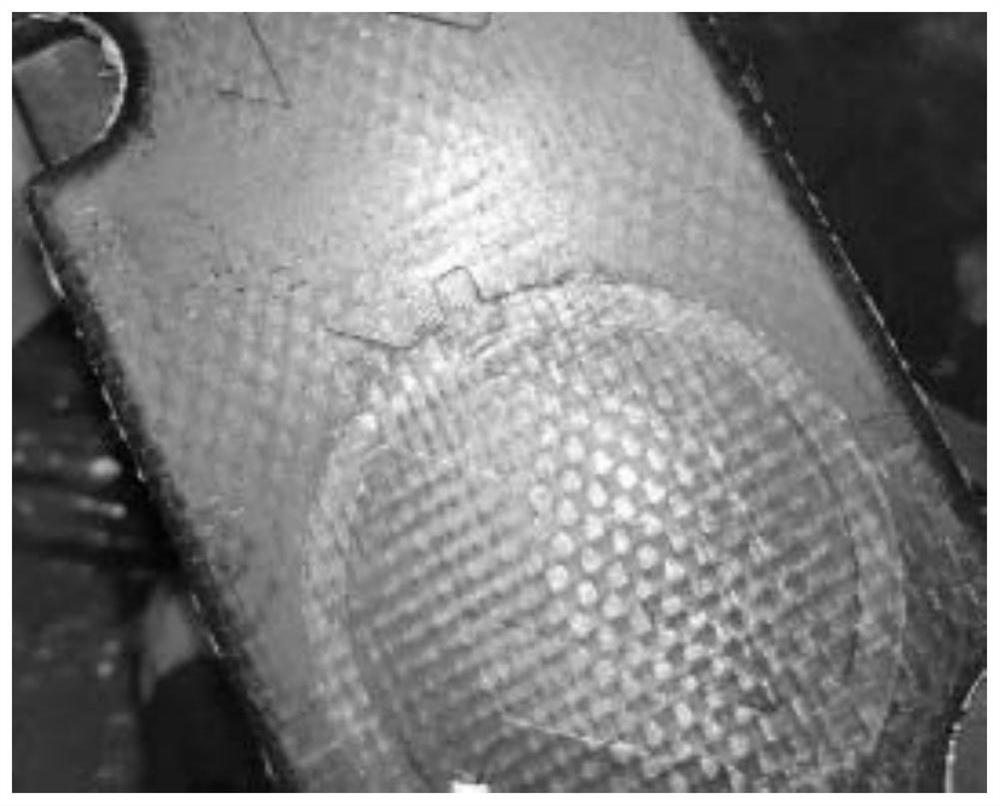

A ceramic brake pad process

ActiveCN110848297BGuaranteed Surface PropertiesGuaranteed finenessOther chemical processesFriction liningProcess engineeringPlastic film

The invention discloses a ceramic brake pad process. The ceramic brake pad process includes the following steps: P2, mixing materials; P3, filtering; P4, hot pressing forming; P5, heat treatment; P6, grinding treatment; P7, surface treatment; P8. Spraying; P9. Packaging: According to the requirements, use a sealing machine and a heat shrinking machine to shrink the finished brake pads in a vacuum through a plastic film, and then pack them into boxes for storage to complete the manufacture of the brake pads. A kind of ceramics provided by the invention The brake pad process adopts reasonable materials and proportions, and filters and sieves after mixing to ensure fineness, improve the compactness of hot pressing, ensure structural strength and wear resistance, and perform heat treatment and surface treatment after hot pressing , to ensure the surface properties of the brake pads, improve the stability of the brakes, facilitate production and processing, and ensure the safety of use.

Owner:温州市松力汽摩配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com