Forming mold and construction method for prefabricated hollowed-out concrete member

A technology for precasting concrete and forming molds, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult demoulding, inconvenient construction and installation, and difficulty in guaranteeing the dimensional accuracy of components, so as to increase the number of repeated demoulding and improve demoulding. The effect of mold efficiency and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

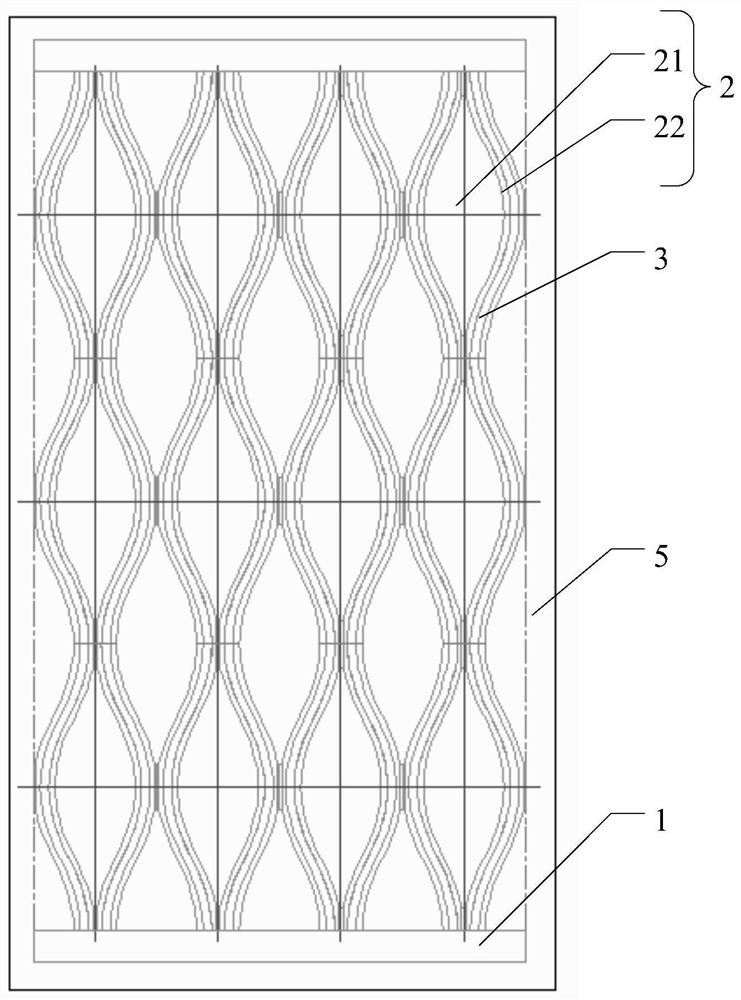

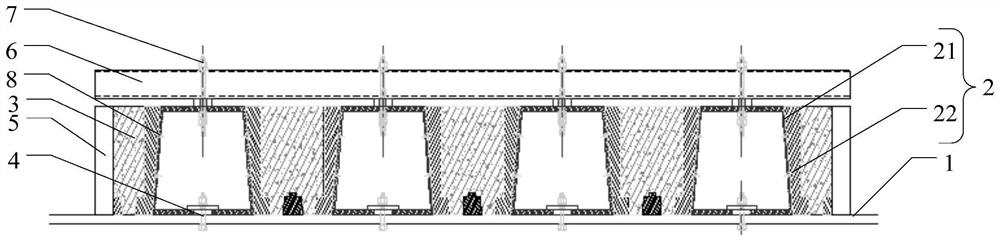

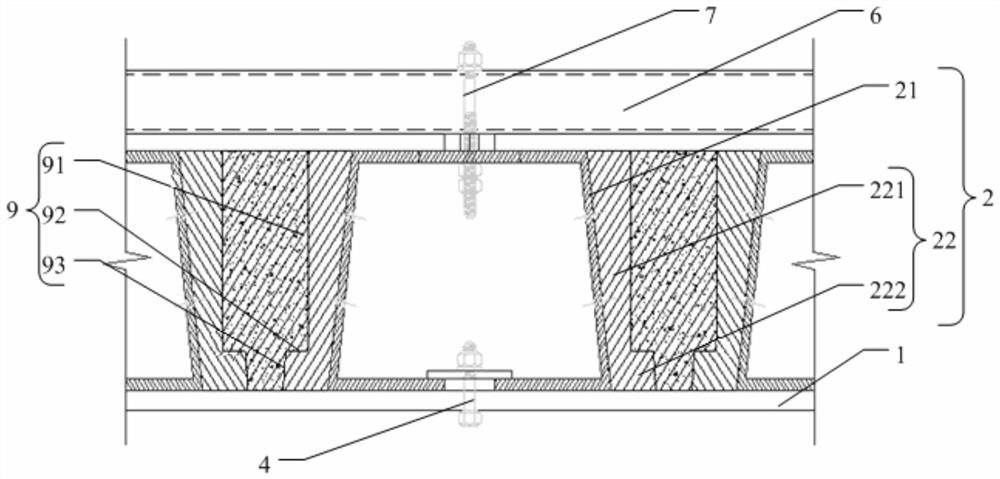

Embodiment 1

[0096] The size of the concrete components required by Dongfang Lvzhou Station on Metro Line 17 is 3885mm wide, 9640mm long, and 300mm thick, which is a super-sized hollowed out concrete component. A plurality of modules are arranged to form a forming structure, so that the precast concrete pouring cavity conforms to the shape of the components to be prepared. The modules are provided with an inner core column and an outer mold layer in sequence from the inside to the outside. The material of the inner core column is steel, and the outer mold layer The material of the layer is polyurethane, and the contact surfaces of the two are combined with a slope. The slope angle of the side of the inner core column relative to the vertical direction is 5°, and the slope angle of the second vertical surface of the outer mold layer relative to the vertical direction is 5°. °, the inner stem and the outer mold layer are integrally formed to form mold 1#. In mold 1#, the module meets W≥u×S, ...

Embodiment 2

[0098] Construct super-sized hollow concrete components, arrange multiple modules to form a molding structure, so that the precast concrete pouring cavity conforms to the shape of the components to be prepared. The material is steel, and the material of the outer mold layer is polyurethane. The contact surface of the two is combined with a slope. The inclination angle in the vertical direction is 85°, and the inner stem and the outer mold layer are integrally formed to form mold 2#. In mold 2#, the module meets W≥u×S, u is 3. After pouring concrete in the prefabricated concrete pouring cavity between adjacent modules, curing and demoulding are carried out to obtain the required oversized prefabricated hollow concrete component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com