A retractable and outwardly retractable expansion and contraction mechanism for a freezer

An external expansion and contraction technology, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as difficult demoulding work and poor demoulding, so as to solve difficult demoulding, improve quality and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

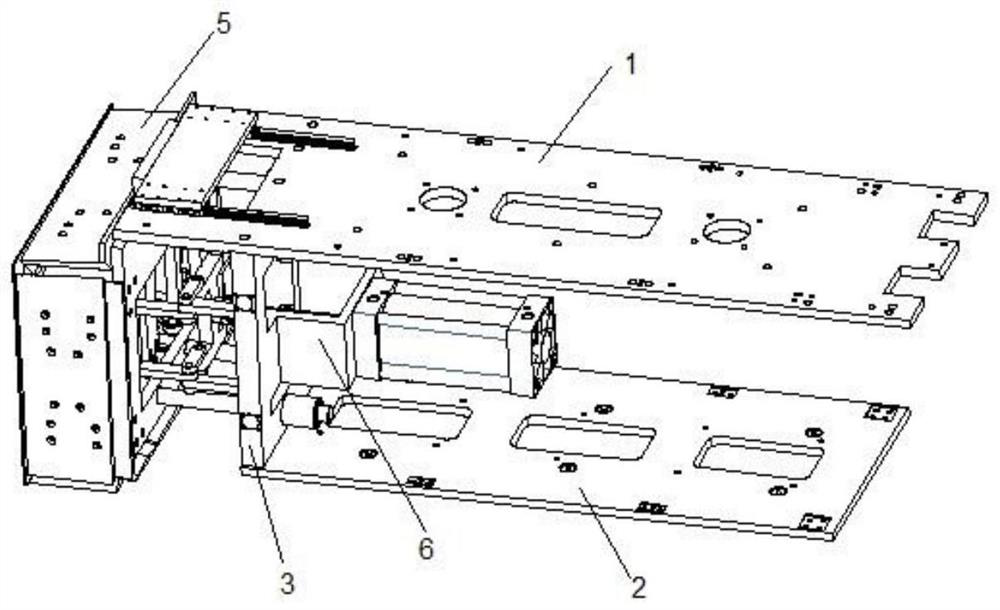

[0030] Now in conjunction with the accompanying drawings, the structural features of the present invention will be described in detail.

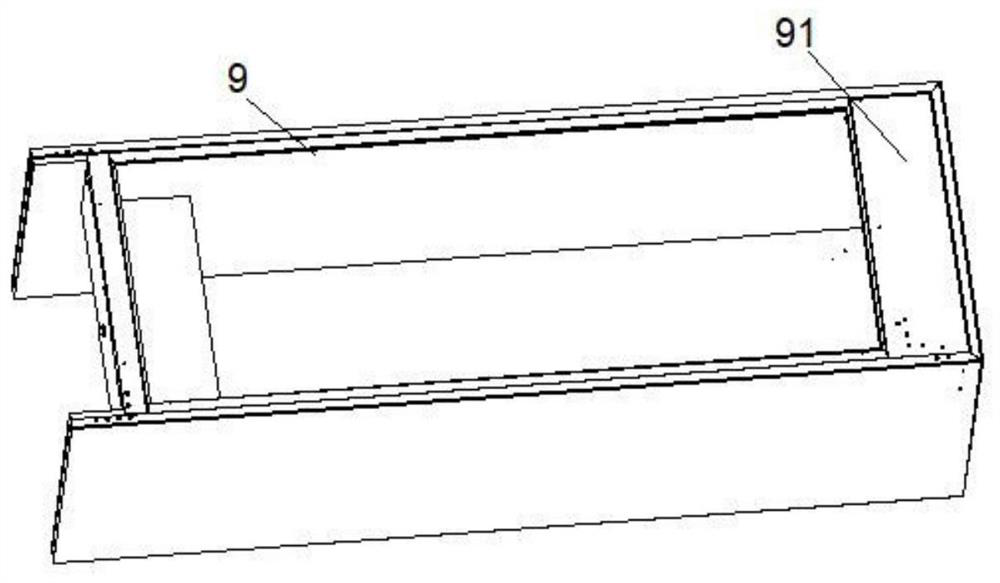

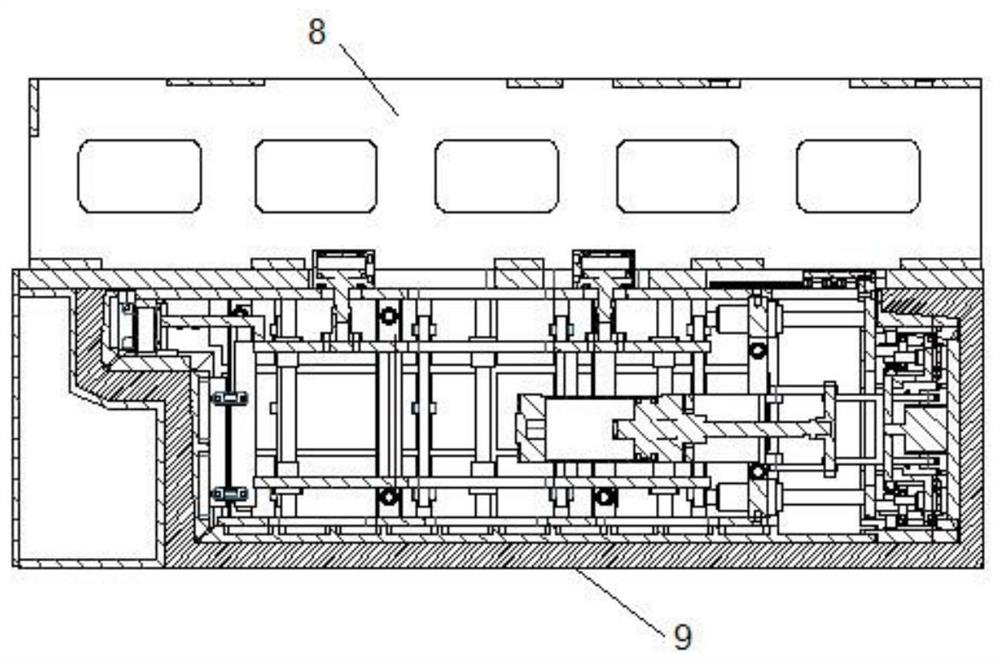

[0031] see figure 1 and combine figure 2 with image 3 , the present embodiment provides an expansion-contraction mechanism for retracting and extending the freezer. The expansion-contraction mechanism is used in the foaming mold 8. When the cabinet body 9 of the refrigerator needs to be prepared, the expansion-contraction mechanism of this embodiment will be installed. The foaming mold 8 of the mechanism is put into the foaming mold box, and the foaming is completed in the foaming mold box. At this time, the expansion-contraction mechanism of this embodiment is in the expanded state, and the expansion-contraction mechanism returns to the contracted state after the foaming is completed. , the undercut 91 part of the freezer cabinet 9 can be demoulded preferably, and the demoulding work of the whole freezer cabinet 9 can be completed. Of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com