Paper bucket volume variable structure and spiral method thereof

A paper drum and volume technology, which is applied in the field of paper drum volume variable structure and its spiral, can solve the problems of increased commodity cost, incompressible side wall of packaging, and arching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment is a structure with a variable volume for a paper drum, which includes a paper drum body and a folding structure that increases or decreases the inner space by screwing together several upper and lower spirals.

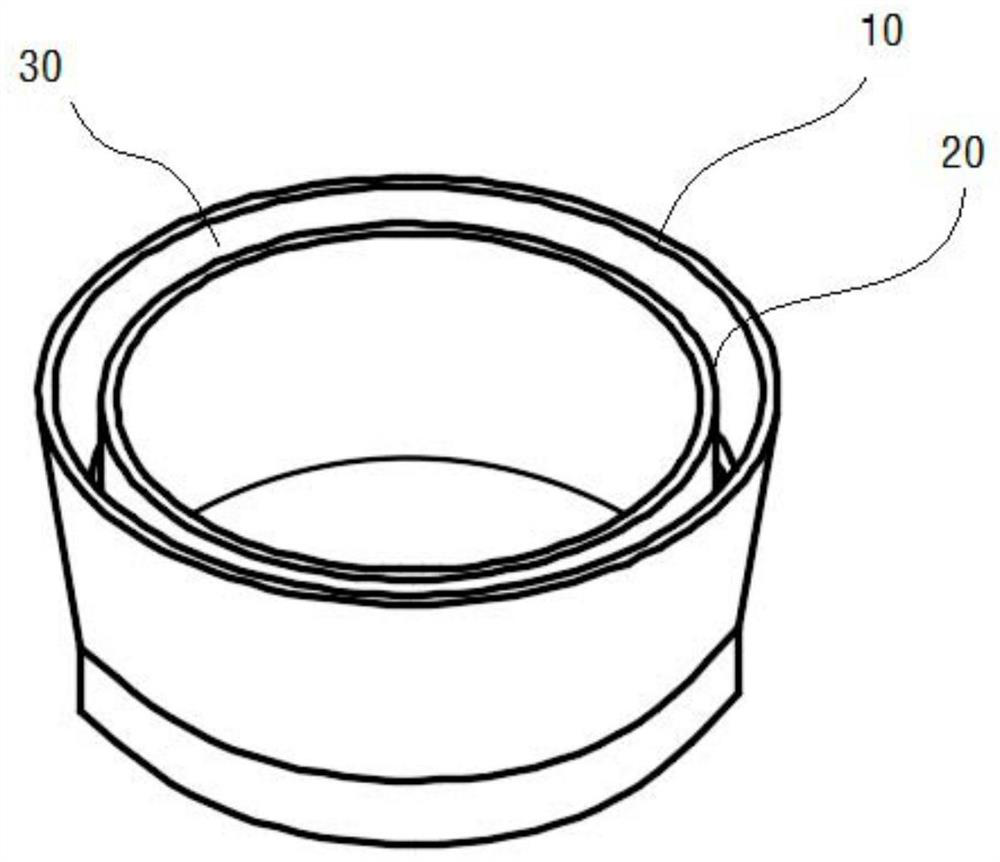

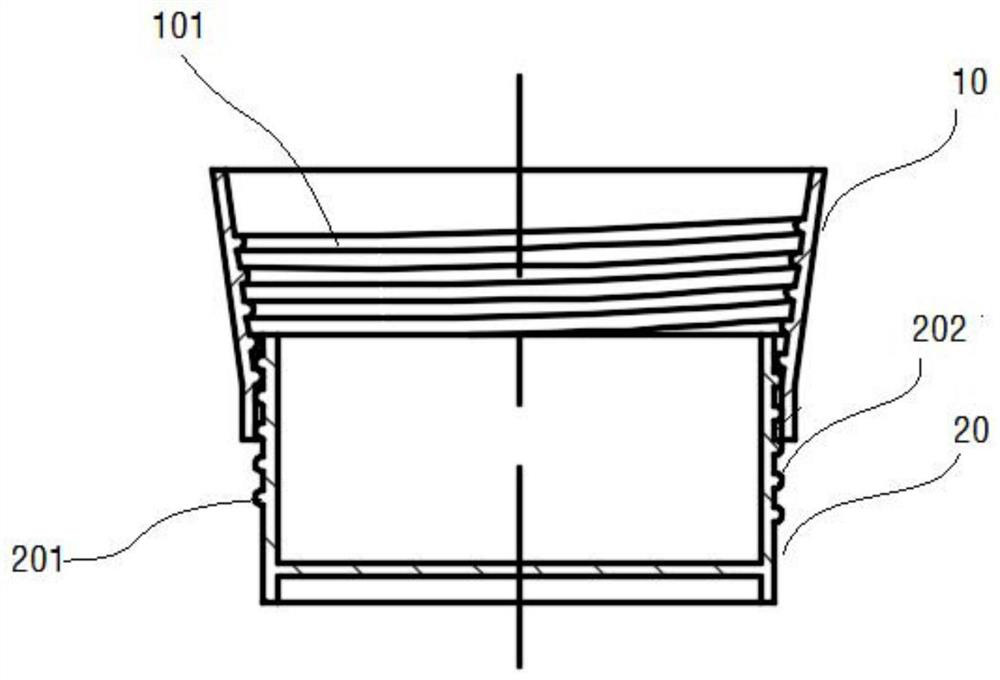

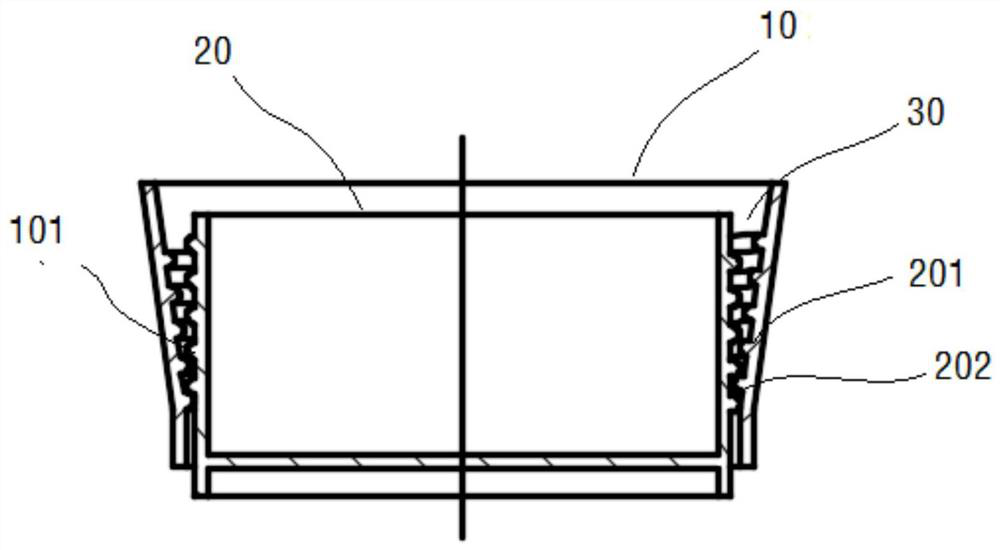

[0034] Specifically, see Figure 1 to Figure 3 As shown, the paper barrel includes an upper spiral part 10 and a lower spiral part 20 of the barrel body, and the upper spiral part of the barrel body and the lower spiral part of the barrel body are separately formed; the upper spiral part 10 of the barrel body is a side wall structure provided with an internal thread 101 The lower screw part 20 of the barrel body is a structure with a bottom bracket provided with an external thread 201 that is externally matched with the internal thread 101 of the upper screw part 10 of the barrel body. interior space.

[0035] Further, the caliber of the upper helical part 10 of the barrel body decreases gradually from top to bottom until the caliber of ...

Embodiment 2

[0040] In order to further increase the volume of the paper barrel, further, the paper barrel can be set into three parts, including the upper spiral part of the barrel body, the middle spiral part of the barrel body and the lower spiral part of the barrel body, the upper spiral part of the barrel body, the middle spiral part and the lower spiral part of the barrel body. The lower spiral portion of the barrel body is formed separately; the upper spiral portion of the barrel body is a side wall structure with internal threads, and the middle spiral portion of the barrel body is a side wall structure with internal threads and external threads; the lower spiral portion of the barrel body is equipped with The inner thread of the upper helical part of the barrel is matched with the outer thread with a bottom support structure.

[0041] When the above-mentioned paper barrel is in use, the user fixes the upper spiral part 10 or the lower spiral part 20 of the barrel, and twists the lo...

Embodiment 3

[0046] Another barrel folding method of this embodiment, see Figure 4 with Figure 5 As shown, the paper drum itself is formed by hot pressing of paper and plastic. The side wall of the integrated paper drum is designed with a spiral structure. The spiral raised structure 40 is wound on the side wall. . The thickness of the barrel wall is uneven, and the thickness of the outer part of the helical structure is thinner, and an indentation line 401 is set along the middle position of the helical structure. When the axial extrusion is compressed, when the outer thinner part receives the extrusion pressure, the helical structure Folding along the creasing line 401, the layers are squeezed together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com