Preparation method of nitrogen-doped graphene material based on 4-amino-1,2,4-triazole-5-one

A technology of nitrogen-doped graphene and graphene, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of graphene materials not easy to compound, application limitations, etc., to increase the free carrier density , improve conductivity and stability, and enhance the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

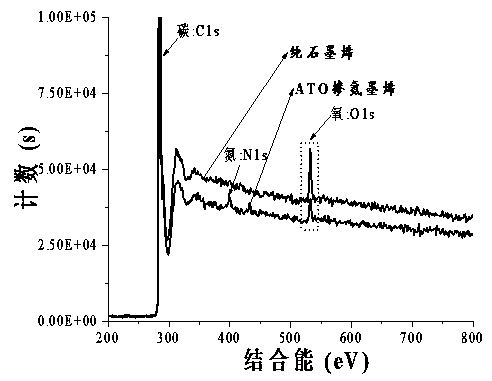

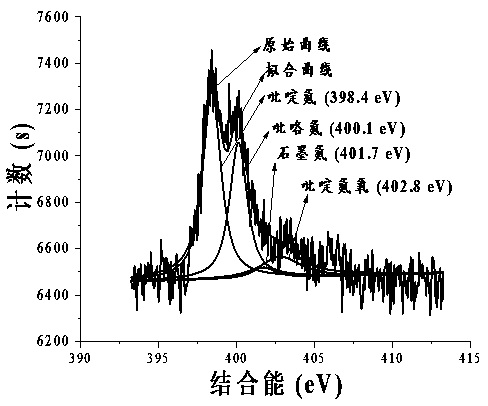

[0019] Add 0.1 g of graphene with a sheet diameter of 0.2 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser, and ultrasonicate for 60 minutes to obtain 4 mg / ml of graphite Alkene solution.

[0020] Dissolve 0.2 g of 4-amino-1,2,4-triazol-5-one into 25ml of deionized water, add the above graphene solution, heat at 100°C for 30min, cool down to 0°C, and dry for 48h to obtain a graphene package coated 4-amino-1,2,4-triazol-5-one co-crystal.

[0021] Grind the graphene-coated 4-amino-1,2,4-triazol-5-one eutectic into powder, place it in a tube furnace and heat it to 600°C for 4 hours to obtain a nitrogen content of 16 . 1% nitrogen doped graphene material.

Embodiment 2

[0023] Add 0.1 g of graphene with a sheet diameter of 100 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser and ultrasonicate for 30 minutes to obtain a 4 mg / ml graphene solution.

[0024] Dissolve 0.1g of 4-amino-1,2,4-triazol-5-one into 25ml of deionized water, add the above graphene solution, heat at 70°C for 60min, cool down to 4°C, and dry for 48h to obtain a graphene package coated 4-amino-1,2,4-triazol-5-one co-crystal.

[0025] Grind the graphene-coated 4-amino-1,2,4-triazol-5-one eutectic into powder, heat it in a tube furnace to 600°C, and keep it for 4 hours to obtain a nitrogen content of 6.11%. Nitrogen-doped graphene materials.

Embodiment 3

[0027] Add 0.1 g of graphene with a sheet diameter of 100 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser and ultrasonicate for 30 minutes to obtain a 4 mg / ml graphene solution.

[0028] Dissolve 0.4g of 4-amino-1,2,4-triazol-5-one into 25ml of deionized water, add the above graphene solution, heat at 70°C for 60min, cool down to 4°C, and dry for 48h to obtain a graphene package coated 4-amino-1,2,4-triazol-5-one co-crystal.

[0029] Grind the graphene-coated 4-amino-1,2,4-triazol-5-one eutectic into powder, heat it in a tube furnace to 600°C, and keep it for 4 hours to obtain a nitrogen content of 8.41%. Nitrogen-doped graphene materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com