A kind of environmental protection water paint for pump industry and preparation method thereof

An environmentally friendly, water-based paint technology, applied in coatings, polyester coatings, anti-corrosion coatings, etc., can solve the problems of paint film corrosion, poor anti-rust ability, high VOC content in paint, high VOC content, etc., to ensure the surface effect and guarantee Saturation and glossiness, affinity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

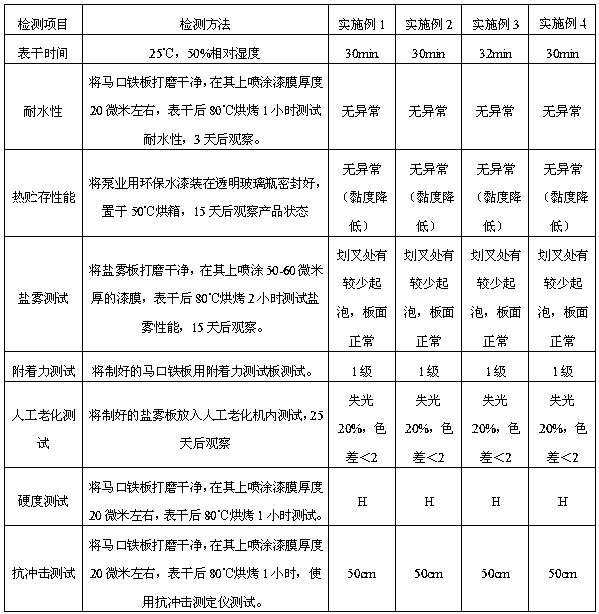

Examples

Embodiment 1

[0041] A kind of environmental protection water paint for pump industry, comprises the raw material of following percentage by weight:

[0042] Water-based resin: 15% polyester polyol;

[0043] Auxiliaries: 0.35% coalescent, 2.1% neutralizer, 1.5% defoamer, 0.2% dispersant, 37% deionized water, 0.1% wetting agent, 1% drier agent;

[0044] Filler: 0.67% carbon black, 6.88% iron oxide black, 7% 808 anti-rust material, 2.5% composite zinc phosphate, 8.8% composite iron-titanium powder, 11.6% barium sulfate, 1% talcum powder, 4.3% anti-settling thixotropic agent.

[0045] Defoamer is that the weight ratio of Tego-810 and BYK-024 is 1:1; Anti-settling thixotropic agent is the organic bentonite of 3wt%; In anti-settling thixotropic agent, organic bentonite: alcohol: the mass ratio of deionized water is 3:1:96; the film-forming aid is dipropylene glycol butyl ether; the neutralizer is triethylamine; the mesh number of talcum powder is 1250 mesh; the mesh number of barium sulfate i...

Embodiment 2

[0052] A kind of environmental protection water paint for pump industry, comprises the raw material of following percentage by weight:

[0053] Water-based resin: 25% polyester polyol;

[0054] Auxiliaries: 0.12% coalescent, 0.9% neutralizer, 0.18% defoamer, 0.15% dispersant, 30% deionized water, 0.25% wetting agent, 0.75% drier agent;

[0055] Filler: 0.31% carbon black, 8.44% iron oxide black, 5% 808 antirust material, 3.3% composite zinc phosphate, 5.5% composite iron titanium powder, 9% barium sulfate, 3.3% talcum powder, 7.8% anti-settling thixotropic agent.

[0056]Defoamer is that the weight ratio of Tego-810 and BYK-024 is 1:1; Anti-settling thixotropic agent is the organic bentonite of 3wt%; In anti-settling thixotropic agent, organic bentonite: alcohol: the mass ratio of deionized water is 3:1:96; the film-forming aid is dipropylene glycol butyl ether; the neutralizer is triethylamine; the mesh number of talcum powder is 1250 mesh; the mesh number of barium sulfat...

Embodiment 3

[0059] A kind of environmental protection water paint for pump industry, comprises the raw material of following percentage by weight:

[0060] Water-based resin: 20% polyester polyol;

[0061] Auxiliaries: 0.2% coalescent, 1.1% neutralizer, 0.2% defoamer, 0.38% dispersant, 31% deionized water, 0.35% wetting agent, 0.75% drier agent;

[0062] Filler: 0.4% carbon black, 12% iron oxide black, 8.8% 808 anti-rust material, 5.3% composite zinc phosphate, 5.72% composite iron-titanium powder, 7% barium sulfate, 1.5% talcum powder, 5.3% anti-settling thixotropic agent.

[0063] Defoamer is that the weight ratio of Tego-810 and BYK-024 is 1:1; Anti-settling thixotropic agent is the organic bentonite of 3wt%; In anti-settling thixotropic agent, organic bentonite: alcohol: the mass ratio of deionized water is 3:1:96; the film-forming aid is dipropylene glycol butyl ether; the neutralizer is triethylamine; the mesh number of talcum powder is 1250 mesh; the mesh number of barium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com