A preparation method of nitrogen-doped graphene with furoxan derivatives as nitrogen source

A nitrogen-doped graphene and derivative technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of limited application scope and the difficulty of compounding graphene materials, and achieve the effect of expanding the application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

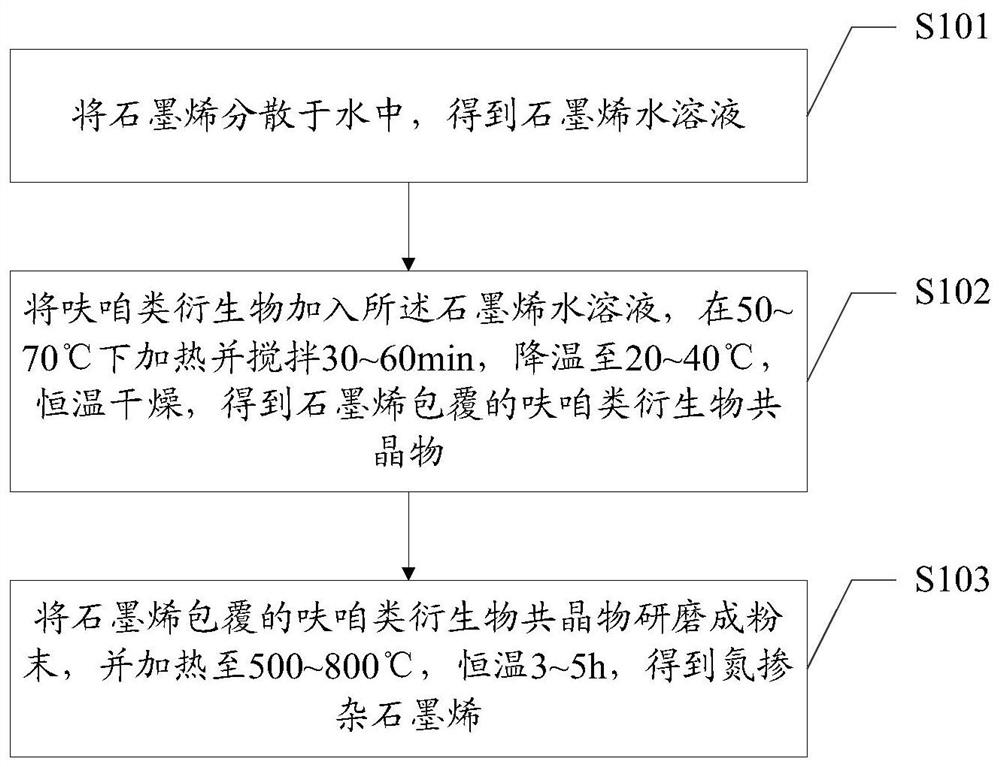

[0019] Please refer to figure 1 , figure 1 The embodiment of the present invention provides a flow chart of a method for preparing nitrogen-doped graphene with furoxan derivatives as a nitrogen source, the method comprising:

[0020] Step 101: disperse graphene in water to obtain graphene aqueous solution. Wherein, the number of layers of the graphene is 1-3 layers.

[0021] Step 102: adding furoxan derivatives to the graphene aqueous solution, heating and stirring at 50-70°C for 30-60min, cooling to 20-40°C, and drying at constant temperature to obtain graphene-coated furoxan derivatives eutectic.

[0022] Wherein, the mass ratio of graphene and furoxan derivatives is 1:6~10; At least one of 4-nitrofurazan (ANF) and the like. The nitrogen content of the furoxan derivatives is 43-58 wt%, for example, DAF is a nitrogen heterocyclic compound with a nitrogen content of 56%.

[0023] Step 103: Grinding the graphene-coated furazan derivative eutectic into powder, heating to 5...

Embodiment 1

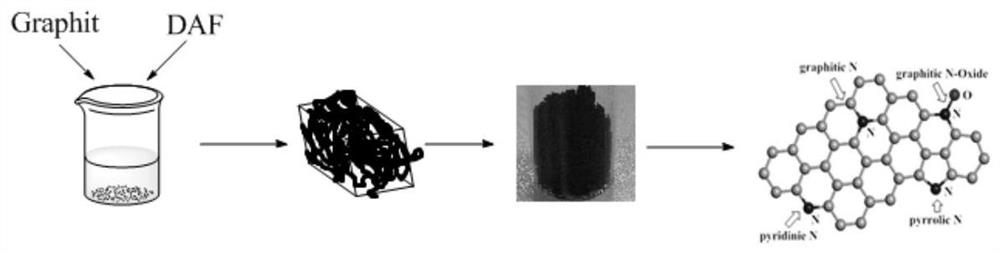

[0029] Such as figure 2 As shown, 0.1g of graphene with a sheet diameter of 0.2μm was added to 25ml of deionized water, stirred magnetically at 600r / min for 60 minutes, then placed in an ultrasonic disperser, and ultrasonically shaken for 60 minutes to obtain 4mg / ml of graphite Alkene solution.

[0030] Add 0.8g DAF to the above 25ml graphene solution, heat at 50°C for 30min until DAF is completely dissolved, cool down to 25°C, and dry the mixed solution in a constant temperature drying oven for 48h to obtain a graphene-coated DAF eutectic .

[0031] The DAF eutectic was ground into powder, placed in a tube furnace and heated to 600°C for 4 hours to obtain nitrogen-doped graphene with a nitrogen content of 5.16%.

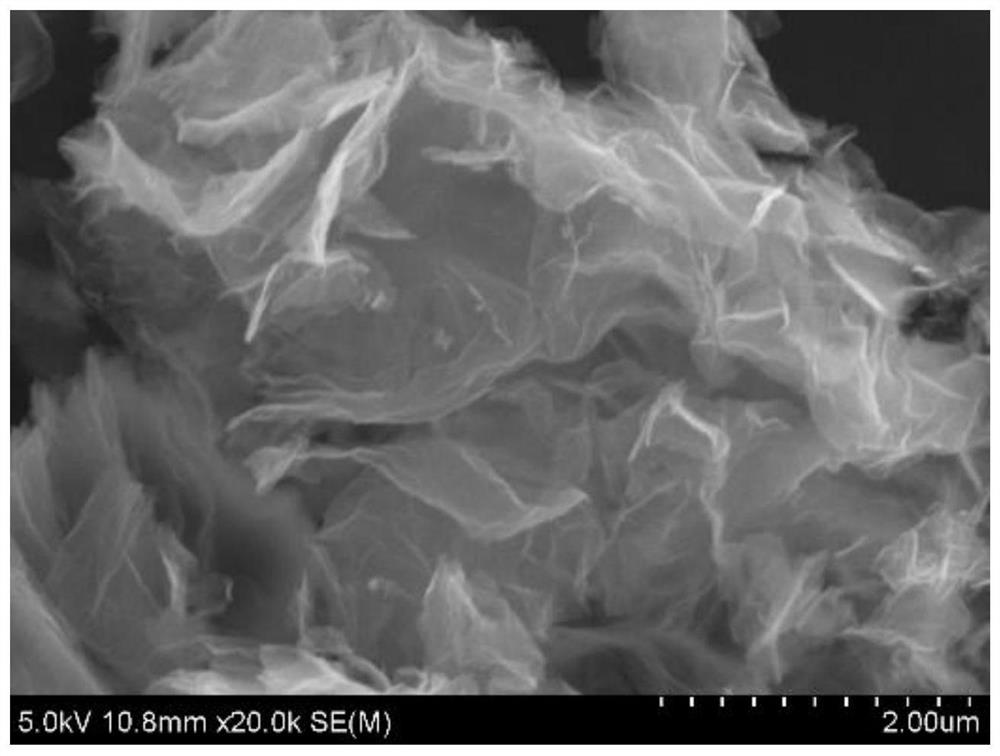

[0032] Such as image 3 Shown is a scanning electron microscope schematic diagram of nitrogen-doped graphene prepared with DAF as a nitrogen source. Depend on image 3 It can be seen that in the nitrogen-doped graphene obtained in the experiment, the graphene ...

Embodiment 2

[0037] Such as figure 2 As shown, 0.1g of graphene with a sheet diameter of 0.5μm was added to 25ml of deionized water, stirred magnetically at 600r / min for 70 minutes, then placed in an ultrasonic disperser, and ultrasonically shaken for 40 minutes to obtain 4mg / ml of graphite Alkene solution.

[0038] Add 1.0g DAAzF to the above 30ml graphene solution, heat at 50°C for 30min until DAAzF is completely dissolved, cool down to 25°C, and dry the mixed solution in a constant temperature drying oven for 48h to obtain a graphene-coated DAAzF eutectic .

[0039] The DAAzF eutectic was ground into powder, placed in a tube furnace and heated to 700°C for 5 hours to obtain nitrogen-doped graphene with a nitrogen content of 6.12%.

[0040] After several experiments, it is feasible to use DAAzF as a nitrogen source to prepare nitrogen-doped graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com