Continuous extrusion forming mold for high-strength copper materials

An extrusion molding, high-strength technology, applied in the direction of metal extrusion dies, etc., can solve the problems of edge tearing, unsaturation, etc., achieve the effects of small frictional resistance, improve processing quality, and improve installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

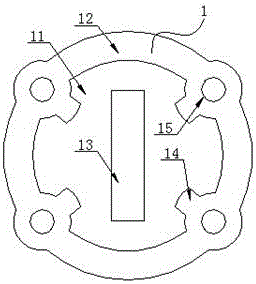

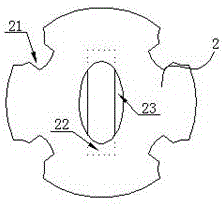

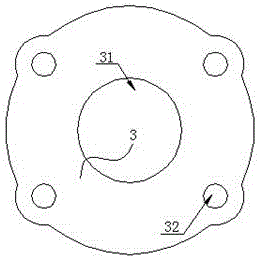

[0015] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0016] Such as Figure 1 to Figure 3 Shown, a kind of high-strength copper material continuous extrusion mold comprises extrusion molding core 2, and described extrusion molding core 2 is made of high-strength die steel, and described high-strength die steel is made of the following by mass percentage Composition: 1.1% Nickel, 0.55% Carbon, 0.23% Silicon, 0.33% Manganese, 0.4% Chromium, 0.4% Tungsten, 0.03% Molybdenum, 0.06% Vanadium, 0.04% Cobalt, 0.004% Molybdenum Tellurium, 0.002% Neodymium, 0.002% Titanium, 0.006% Boron, balance Iron.

[0017] Specifically, it also includes a core installation cover 1 and a core installation cover 3. The core installation cover 1 includes a round cake-shaped installation support bottom surface 11 and a circular tube-shaped installation support side 12. The installation support The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com