Preparation method of nitrogen-doped graphene material containing 3, 5-diamino-1H-1, 2, 4-triazole

A nitrogen-doped graphene and diamino technology, which is applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of limited application and difficult compounding of graphene materials, so as to expand applications and improve free loading. Effects of carrier density, improved conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

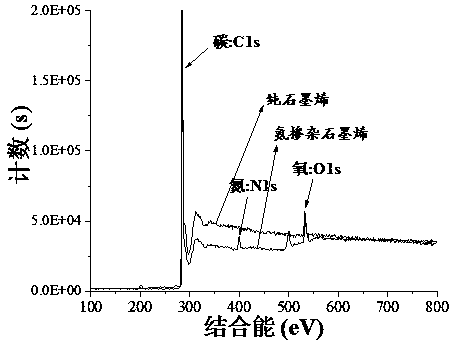

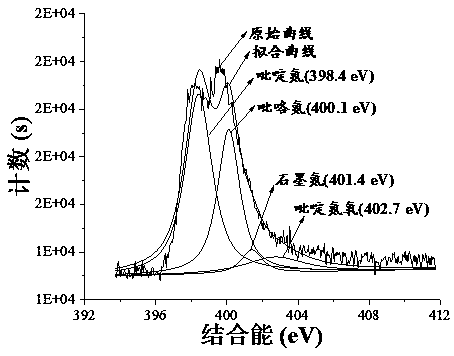

[0019] 0.1 g of graphene with a sheet diameter of 0.2 μm was added to 25 ml of deionized water, stirred magnetically at 600 r / min for 60 minutes, then placed in an ultrasonic disperser and ultrasonicated for 60 minutes to obtain a 4 mg / ml graphene solution.

[0020] Dissolve 0.2 g of 3,5-diamino-1-hydrogen-1,2,4-triazole into 25ml of deionized water, add the above graphene solution, heat at 100°C for 30min, cool down to 0°C, and dry for 48h to obtain graphite 3,5-diamino-1-hydrogen-1,2,4-triazole co-crystal coated with ene.

[0021] Grind the graphene-coated 3,5-diamino-1hydrogen-1,2,4-triazole eutectic into powder, heat it in a tube furnace to 600°C, and keep it for 4 hours to obtain a nitrogen content of 12.02% nitrogen doped graphene material.

Embodiment 2

[0023] Add 0.1 g of graphene with a sheet diameter of 100 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser and ultrasonicate for 30 minutes to obtain a 4 mg / ml graphene solution.

[0024] Dissolve 0.1g of 3,5-diamino-1-hydrogen-1,2,4-triazole into 25ml of water, add the above graphene solution, heat at 70°C for 60min, cool down to 4°C, and dry for 48h to obtain a graphene package Coated 3,5-diamino-1-hydrogen-1,2,4-triazole eutectic.

[0025] Grind the graphene-coated 3,5-diamino-1hydrogen-1,2,4-triazole eutectic into powder, heat it in a tube furnace to 600°C, and keep it for 4 hours to obtain a nitrogen content of 8.02% nitrogen doped graphene material.

Embodiment 3

[0027] Add 0.1 g of graphene with a sheet diameter of 100 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser and ultrasonicate for 30 minutes to obtain a 4 mg / ml graphene solution.

[0028] Dissolve 0.4g of 3,5-diamino-1hydrogen-1,2,4-triazole into 25ml of deionized water, add the above graphene solution, heat at 70°C for 60min, cool down to 4°C, and dry for 48h to obtain graphite 3,5-diamino-1-hydrogen-1,2,4-triazole co-crystal coated with ene.

[0029] Grind the graphene-coated 3,5-diamino-1hydrogen-1,2,4-triazole eutectic into powder, heat it in a tube furnace to 600°C, and keep it for 4 hours to obtain a nitrogen content of 10.02% nitrogen doped graphene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com