D450 electronic yarn impregnating agent and preparation method thereof

A technology of sizing agent and electronic yarn, which is applied in the field of glass fiber yarn, can solve the problems that the sizing agent is easy to fall off, affects the surface performance of the electronic base cloth, and increases the hairiness of the cloth surface, and achieves the reduction of hairiness, low cost, and non-irritating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

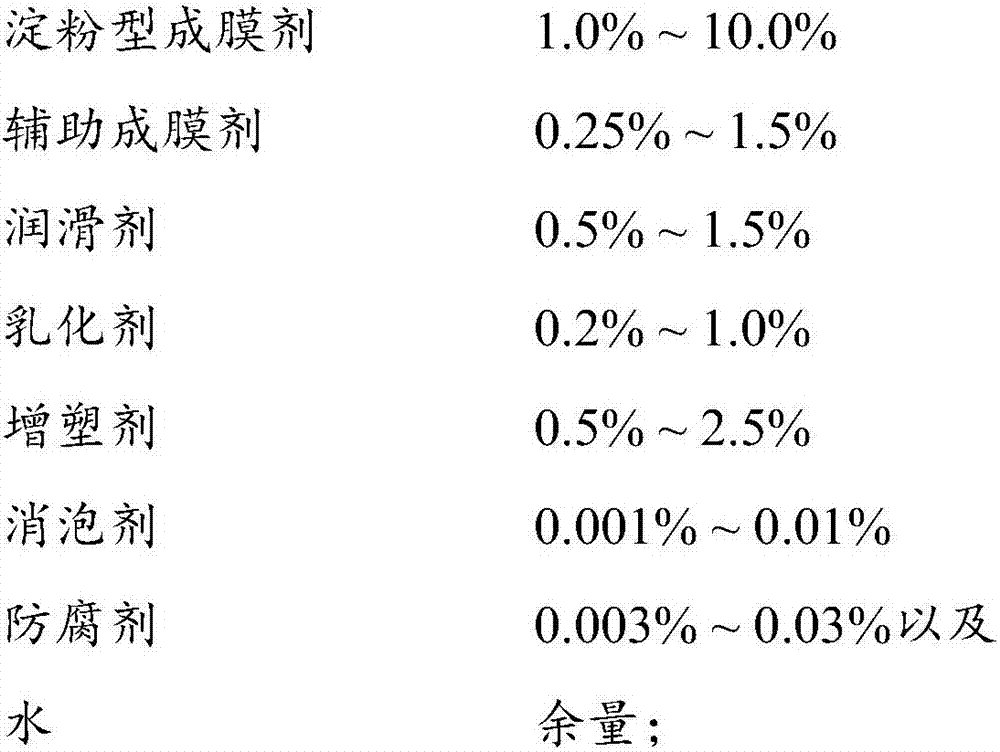

Method used

Image

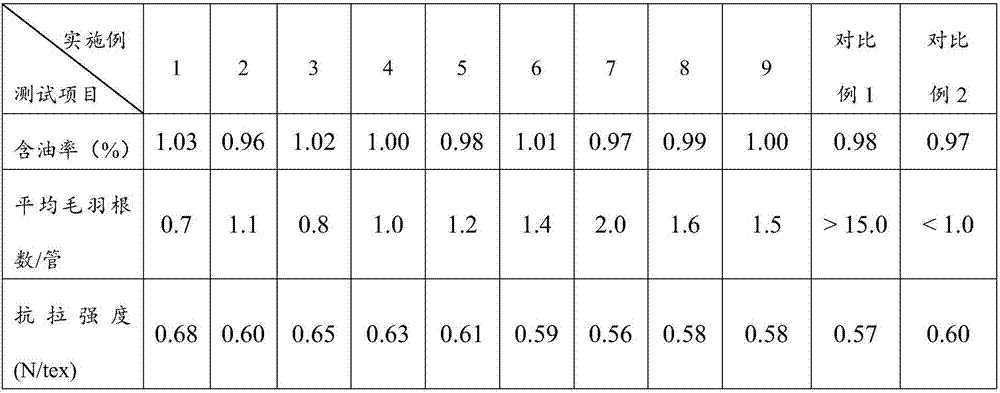

Examples

Embodiment 1

[0036] The present embodiment provides a D450 electronic yarn sizing agent, including the following raw materials in mass percentage: 2.05% high amylose modified starch, 2.05% hydroxypropyl modified starch, 0.51% P-70 water-based epoxy resin, 0.42% ethyl alcohol Glycol propylene glycol block polyether, 2.05% polyethylene glycol PEG4000, 0.20% triglyceride, 0.61% petrolatum, 0.0072% preservative, 0.001% defoamer and the balance deionized water. The preparation process of the D450 electronic yarn sizing agent of this embodiment includes the following steps:

[0037] (1) Add the emulsifier into the hot-melted triglyceride and petroleum oil according to the dosage of the above-mentioned components, emulsify and homogenize, and obtain a lubricant solution.

[0038] (2) Add the starch-type film-forming agent into an appropriate amount of water, stir and disperse, then raise the temperature to 90°C-100°C, keep it warm for 20min-30min, and then cool it down to 50°C-65°C to obtain star...

Embodiment 2

[0041] The present embodiment provides a D450 electronic yarn sizing agent, comprising the following raw materials in mass percentage: 1.97% of high amylose modified starch, 1.97% of hydroxypropyl modified starch, 0.75% of P-70 water-based epoxy resin, 0.42% of ethyl alcohol Glycol propylene glycol block polyether, 1.97% of polyethylene glycol PEG4000, 0.20% of triglyceride, 0.61% of petroleum oil, 0.0065% of preservative, 0.001% of defoamer and the balance of deionized water. The preparation process of the D450 electronic yarn sizing agent in this example is the same as that in Example 1, that is, the D450 electronic yarn sizing agent with a solid content of 6.00% is obtained.

Embodiment 3

[0043] The present embodiment provides a D450 electronic yarn sizing agent, including raw materials in mass percentage: 2.15% high amylose modified starch, 2.15% hydroxypropyl modified starch, 0.27% P-70 water-based epoxy resin, 0.42% ethyl alcohol Glycol propylene glycol block polyether, 2.15% polyethylene glycol PEG4000, 0.20% triglyceride, 0.61% petrolatum, 0.0075% preservative, 0.001% defoamer and the balance deionized water. The preparation process of the D450 electronic yarn sizing agent in this example is the same as in Example 1, that is, the D450 electronic yarn sizing agent with a solid content of 6.50% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com