Lightweight high-strength concrete material with self-leveling characteristic and preparation and construction methods thereof

A high-strength concrete and self-leveling technology, which is applied in the processing of building materials, construction, building construction, etc., to reduce construction difficulty, improve strength and frost resistance, and avoid damage and noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

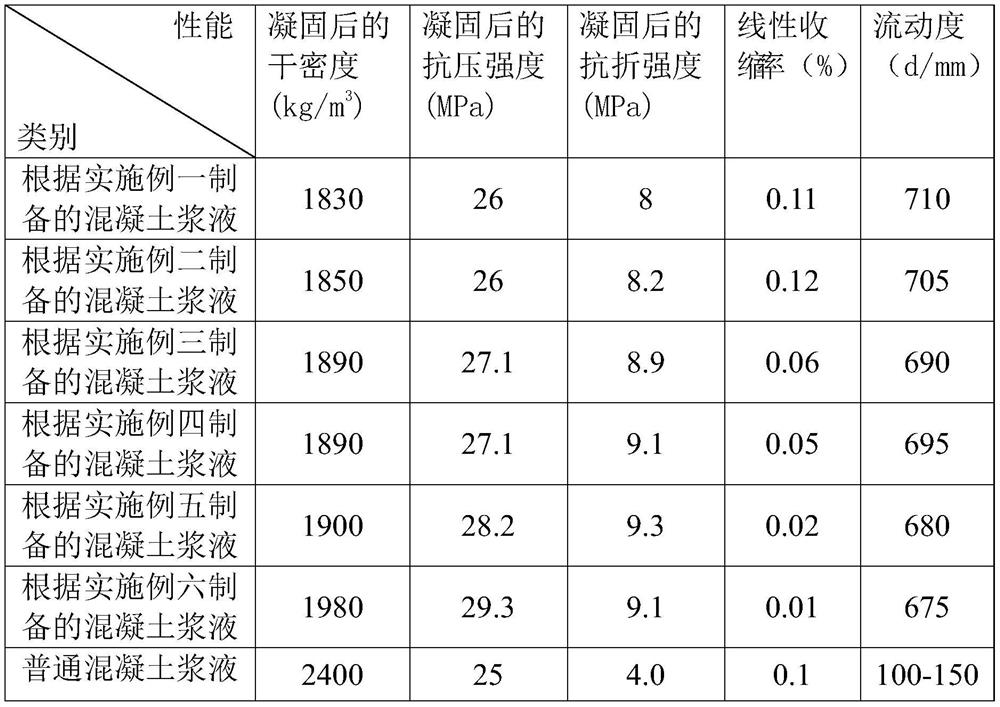

Examples

preparation example Construction

[0037] A kind of preparation method of the lightweight high-strength concrete material with self-leveling characteristics of the present invention comprises the following steps,

[0038] Step (A1), preparing the following components and the parts by weight of each component, ordinary cement: 175-200 parts; high belite cement: 10-30 parts; anhydrite: 15-20 parts; heavy calcium powder: 52 -80 parts; kaolin: 0-35 parts; yellow sand: 522.5-672.5 parts; pea stone: 0-150 parts; hydroxypropyl methylcellulose: 0.1-1.2 parts; water reducing agent: 1-8 parts; expansion agent : 1-10 parts; slag: 0-30 parts; defoamer: 0.1-0.5 parts; anti-cracking agent: 0.1-0.6 parts; anti-cracking fiber: 1-5 parts; 0.1-0.8 parts; Fumed silica: 0.1-2 parts;

[0039] Step (B1), sequentially adding materials other than yellow sand, bean stone and slag into the disperser for dispersion treatment to obtain powder materials;

[0040] The rotational speed of the disperser for the dispersing treatment in the a...

Embodiment 1

[0053] A kind of lightweight high-strength concrete material with self-leveling characteristics of the present invention comprises the following components and the parts by weight of each component:

[0054] Ordinary cement: 200 parts; high belite cement: 20 parts; anhydrite: 20 parts; heavy calcium powder: 80 parts; kaolin: 0 parts; yellow sand: 672.5 parts; pea stone: 0 parts; Element: 0.5 parts; Water reducing agent: 2 parts; Expansion agent: 5 parts; Slag: 0 parts; Defoamer: 0.3 parts; Anti-cracking agent: 0.5 parts; Tartaric acid: 0.3 parts; fumed silica: 1 part; and added water: 120 parts.

Embodiment 2

[0056] A kind of lightweight high-strength concrete material with self-leveling characteristics of the present invention comprises the following components and the parts by weight of each component:

[0057] Ordinary cement: 200 parts; high belite cement: 20 parts; anhydrite: 20 parts; heavy calcium powder: 80 parts; kaolin: 0 parts; yellow sand: 622.5 parts; bean stone: 50 parts; Element: 0.5 parts; Water reducing agent: 2 parts; Expansion agent: 5 parts; Slag: 10 parts; Defoamer: 0.3 parts; Anti-cracking agent: 0.5 parts; Tartaric acid: 0.3 parts; fumed silica: 1 part; and added water: 120 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com