Open one-scraper structure

A technology of scraper and scraper blade, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of easy occurrence of knife wire, inability to eliminate, and short service life of micro-concave rollers, and achieve practical effect, simple structure, Guaranteed effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

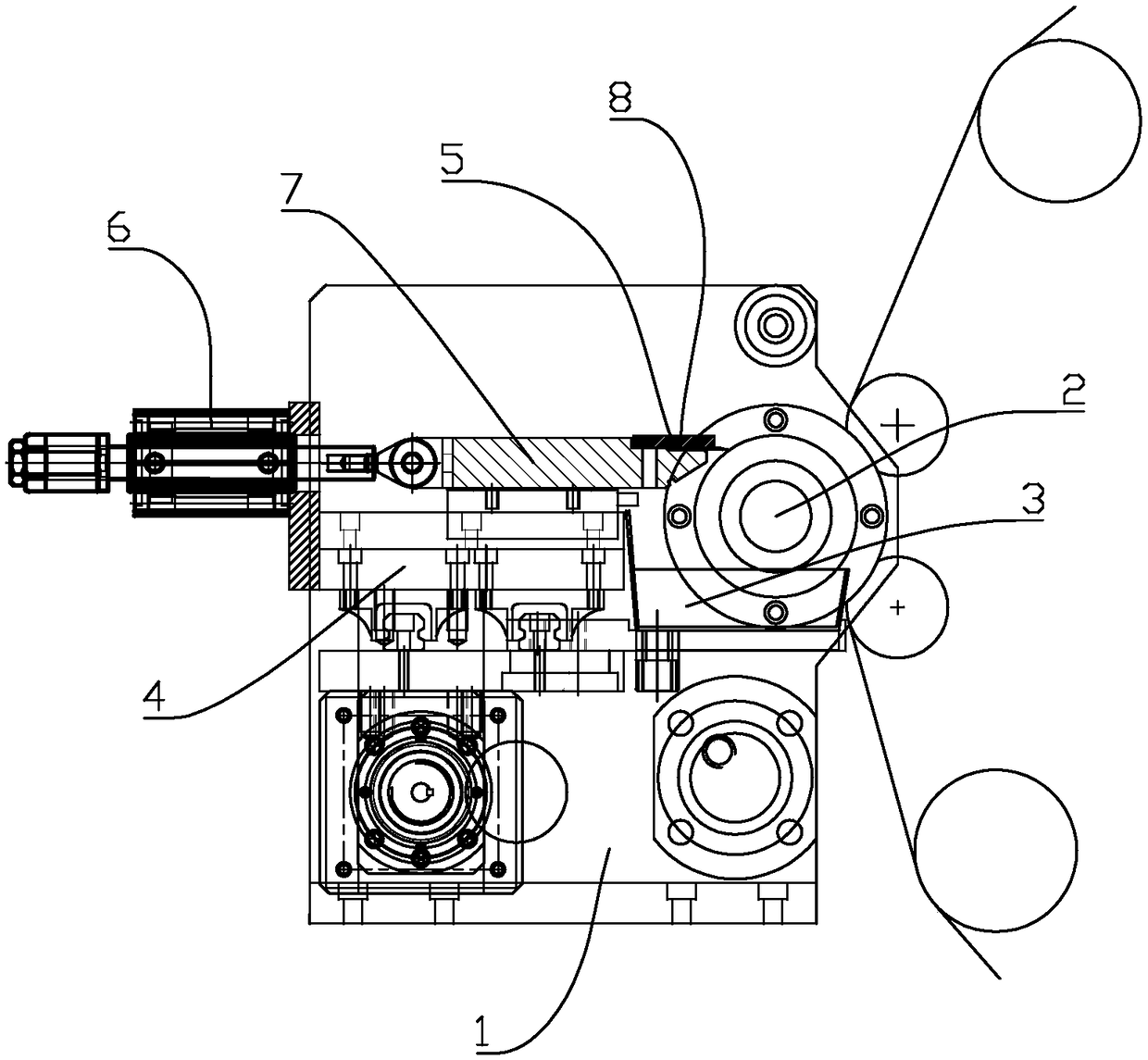

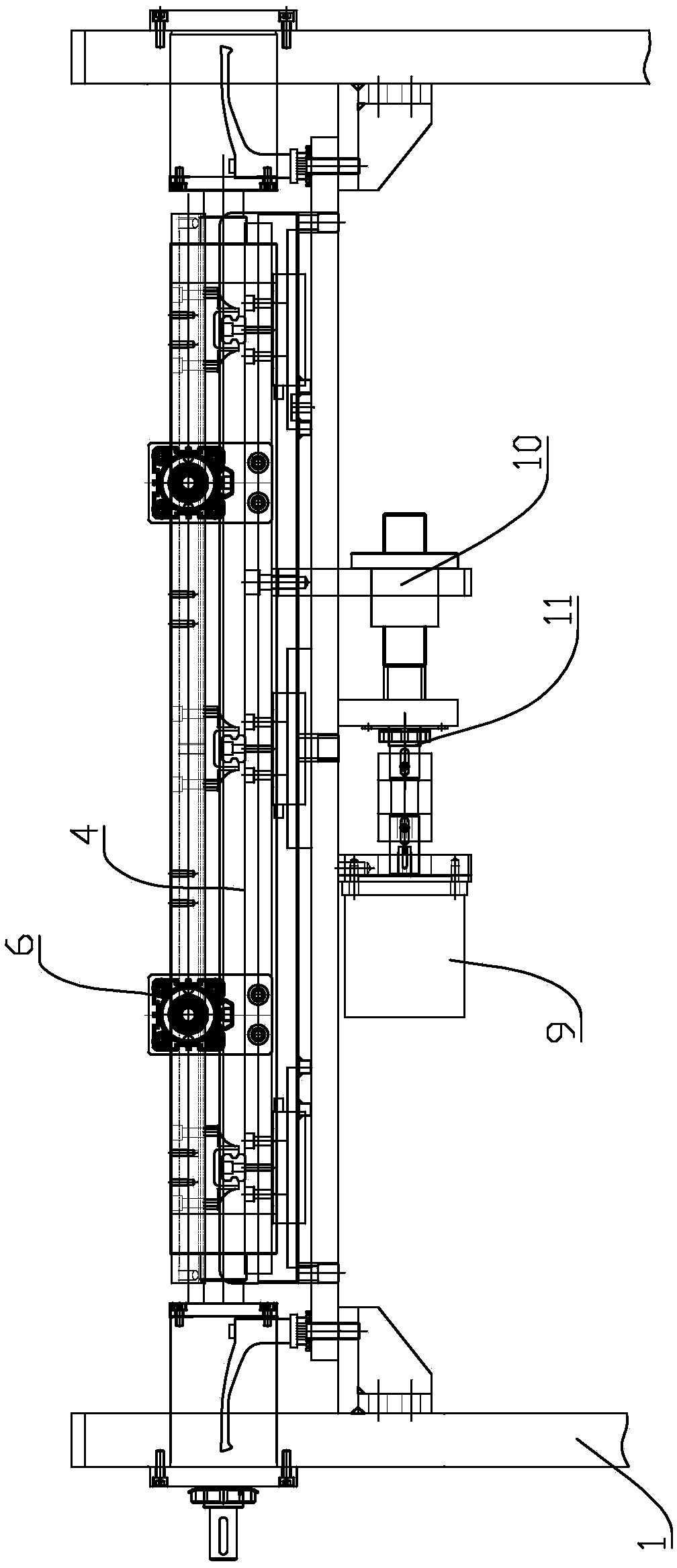

[0019] refer to Figure 1 ~ Figure 2 , the present invention is an open single scraper structure, comprising: a frame 1, a micro-concave roller 2 is rotatably mounted on the frame 1, and a material basin 3 is arranged under the micro-concave roller 2;

[0020] The sliding seat 4 is horizontally slidably mounted on the frame 1, and the moving track of the sliding seat 4 is parallel to the center line of the dimple roller 2;

[0021] The driving mechanism is installed on the frame 1 and is used to drive the sliding seat 4 to move;

[0022] The scraper assembly is installed on the sliding seat 4. The above embodiment drives the sliding seat 4 to slide on the frame 1 through the driving mechanism, and then drives the scraper assembly to slide horizontally. Even if there is a gap at the edge of the scraper assembly, it can be eliminated through other intact parts of the blade when the scraper assembly slides laterally. The knife wire ensures the coating surface effect, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com