Scale inhibiting dispersant composition and use thereof

A composition and material technology, applied in the direction of scale removal and water softening, natural water treatment, chemical instruments and methods, etc., can solve the problems of chilling water volume and heat exchange efficiency reduction, equipment and pipeline deposition, scaling and deposition, etc. , to achieve the effect of inhibiting scaling, reducing complexity and workload, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

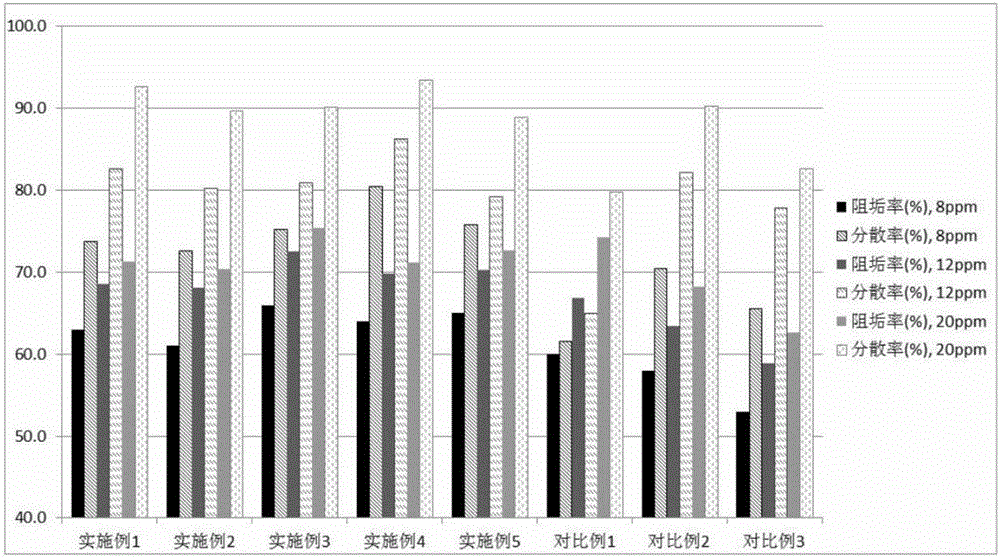

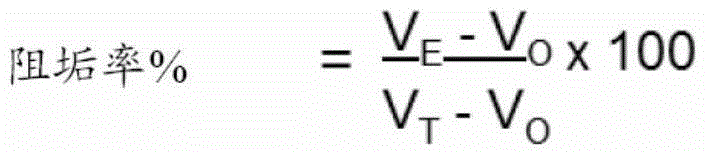

Examples

Embodiment 1

[0055] An aqueous composition containing) 27.6 g of component 1) and 12 g of component 2) was prepared by the following method:

[0056] 1. 60g of sodium acrylate polymer (purchased from Nalco Company, product number PR4512, solution concentration is 46wt.%) is loaded into the reactor;

[0057] 2. Slowly add the copolymer of 40g of acrylic acid and sodium p-styrene sulfonate (available from Nalco Company, product number PR4848, solution concentration is 30wt.%) to the reactor and stir to make the components fully mix.

Embodiment 2

[0059] An aqueous composition containing 9.2 g of component 1), 35.25 g of component 2) and 2.4 g of component 4) was prepared by the following method:

[0060] 1. 20 g of sodium acrylate polymer (purchased from Nalco Company, product number PR4512, solution concentration is 46wt.%) is loaded into the reactor;

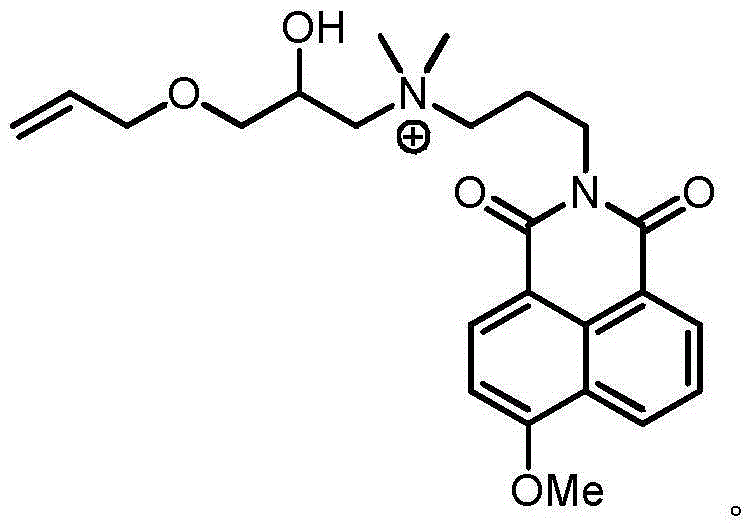

[0061] 2. Slowly add 75g of acrylic acid, 2-acrylamide-2-methylpropanesulfonate sodium and 4-MNDMAPN-HAPQ copolymer (purchased from Nalco Company, product number D04C0, solution concentration is 47wt.%) into the reactor and agitate to allow the components to mix thoroughly;

[0062] 3, open the tap of cooling jacket, then 5g NaOH solution (purchased from Nalco Company, commodity number R-7480, solution concentration is 48wt.%) very slowly adds in the described reactor to adjust pH value to 10 , then continue stirring until the ingredients are fully combined.

Embodiment 3

[0064] An aqueous composition containing 8 g of component 1), 12 g of component 2) and 20 g of component 3) was prepared by the following method:

[0065] 1. 20g of acrylic acid / maleic acid copolymer (purchased from BASF, product number CP5, solution concentration is 40wt.%) is loaded into the reactor;

[0066] 2. Slowly add the copolymer of 40g of acrylic acid and sodium p-styrene sulfonate (available from Nalco Company, product number PR4848, solution concentration is 30wt.%) to the reactor and stir to make the components fully mix;

[0067] 3. Slowly add 40 g of 2-phosphorylbutane-1,2,4-tricarboxylic acid solution (purchased from Nalco Company, product number R-2244, solution concentration is 50wt.%) to the reactor Neutralize and stir to combine ingredients well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com