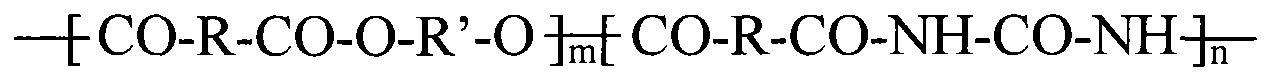

Degradable unsaturated polyester amide urea copolymer and synthesizing method

A polyester amide urea, synthesis method technology, applied in the field of polymer materials, can solve the problems of poor performance, high cost, application limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: One of the synthetic methods of unsaturated polyester amide urea resin:

[0025] Mix 0.40 mol of maleic anhydride, 0.1 mol of urea and 0.31 mol of neopentyl glycol, put it into a 250ml three-neck flask with a water separator, place it in a silicone oil bath, stir it electrically, and react at 100°C for 20 minutes. The temperature was raised to 150° C. for 40 minutes for melt polymerization in a nitrogen atmosphere, then the temperature was raised to 180° C. for 120 minutes for melt polymerization in a nitrogen atmosphere, and then the temperature was raised to 200° C. for 30 minutes for melt polymerization in a nitrogen atmosphere. When the distilled reaction water reaches 80% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C. and poured out. After cooling, a light brown transparent semi-solid unsaturated polyester amide urea resin is obtained.

Embodiment 2

[0026] Embodiment 2: the synthetic method two of unsaturated polyester amide urea resin:

[0027] Mix 0.20 moles of maleic anhydride, 0.20 moles of phthalic anhydride, 0.1 moles of urea, 0.23 moles of dipropylene glycol, and 0.10 moles of ethylene glycol, put them into a 250ml three-necked flask with a water separator, and place them in a silicone oil bath , electric stirring, and react at 100°C for 20 minutes. Heating up to 150°C, melt polymerization in a nitrogen atmosphere for 40 minutes, then raising the temperature to 180°C, melt polymerization in a nitrogen atmosphere for 120 minutes, then raising the temperature to 200°C, melt polymerization in a nitrogen atmosphere for 60 minutes, and melt polymerization in a nitrogen atmosphere for 60 minutes. When the distilled reaction water reaches 80% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C. and poured out. After cooling, a light yellow transparent semi-solid unsaturated polye...

Embodiment 3

[0028] Embodiment 3: the synthetic method three of unsaturated polyester amide urea resin:

[0029] Mix 0.20 moles of maleic anhydride, 0.20 moles of phthalic anhydride, 0.1 moles of urea, 0.20 moles of propylene glycol, and 0.10 moles of polyethylene glycol (400), put them into a 250ml three-necked flask with a water separator, and place In a silicone oil bath, with electric stirring, react at 100°C for 20 minutes. Raise the temperature to 150°C, melt polymerization in a nitrogen atmosphere for 40 minutes, then raise the temperature to 180°C, melt polymerization in a nitrogen atmosphere for 120 minutes, then raise the temperature to 200°C, melt polymerization in a nitrogen atmosphere for 60 minutes, and the reaction water to be distilled reaches the theoretical amount At 80% of the concentration, the polymerization was stopped, the temperature was lowered to 150°C and poured out, and a light yellow transparent semi-solid unsaturated polyester amide urea resin was obtained aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com