Porous ferroferric oxide/ carbon nanometer rod-shaped electromagnetic wave absorbing material and preparing method and application thereof

A technology of ferroferric oxide and carbon nanorods, which is applied in the direction of iron oxide/hydroxide, magnetic materials, nano-carbon, etc., can solve the problems of unfavorable wave-absorbing material stability and weak oxidation resistance of metal cobalt, and achieve Excellent electromagnetic wave absorption performance, high saturation magnetic susceptibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Technical scheme of the present invention is as follows:

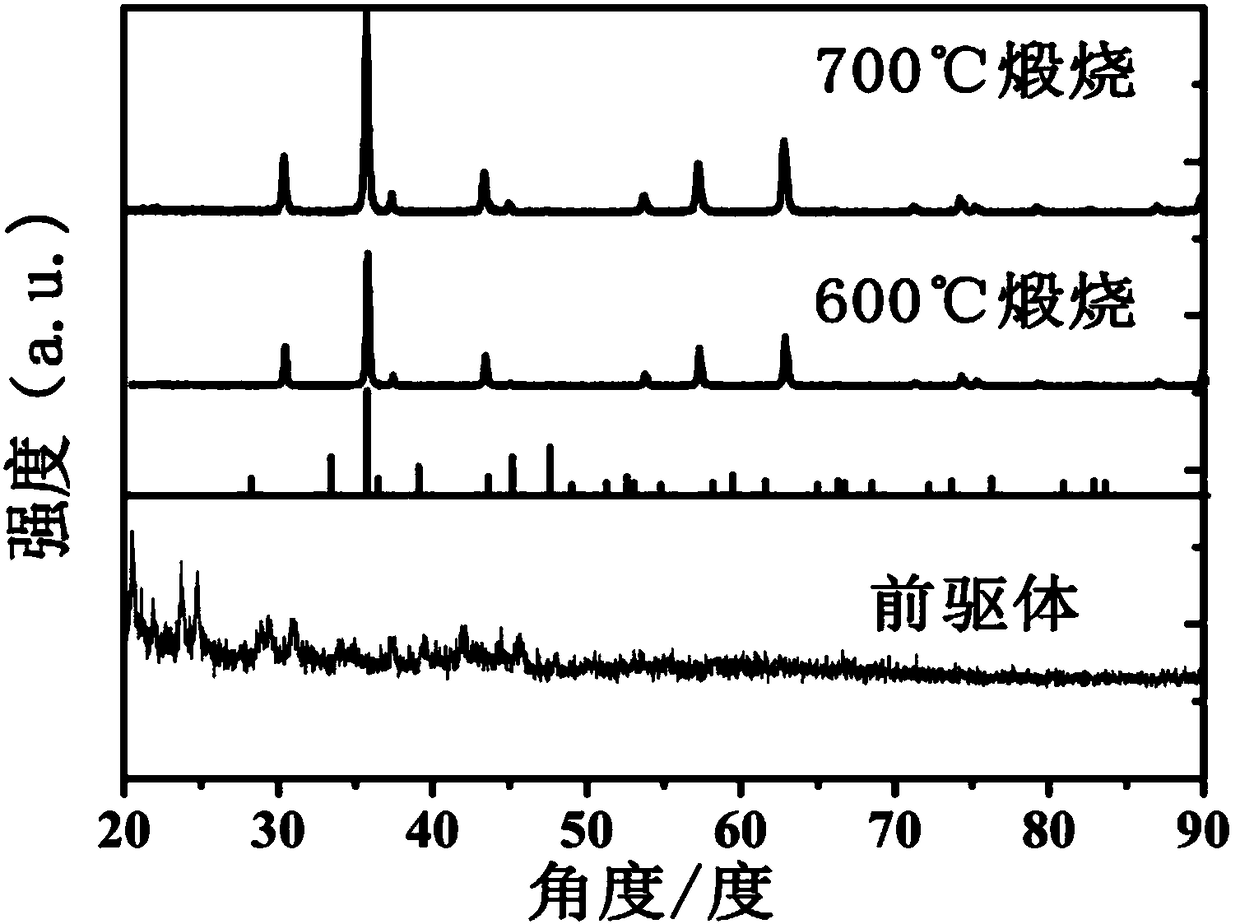

[0008] A porous Fe3O4 / carbon nanorod composite electromagnetic wave absorbing material, which is a multiphase nanocomposite powder composed of carbon and Fe3O4; wherein, Fe3O4 particles are embedded in the carbon sheet to form a porous structure of monodisperse nanorods.

[0009] According to the present invention, preferably, the composite electromagnetic wave absorbing material has a size of 1.0-1.2 μm and a pore diameter of 1-20 nm. The pore structure exists between the particles of Fe3O4 and inside the nano-carbon layer.

[0010] According to the present invention, preferably, the size of the ferric oxide particles is 40-50 nm.

[0011] According to the present invention, preferably, in the porous ferric oxide / carbon nanorod composite material, the mass ratio of carbon to ferric oxide is (1-40):(60-99).

[0012] According to the present invention, preferably, the carbon is amorphous carbon.

[0013] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com