Three-dimensional porous manganese oxide-cobalt composite electromagnetic wave absorbing material and its preparation method and application

A technology of three-dimensional porous and absorbing materials, which is applied in electrical components, metal processing equipment, magnetic field/electric field shielding, etc., can solve the problems of narrow effective absorption bandwidth, poor impedance matching characteristics, strong electromagnetic wave reflection, etc., to improve electromagnetic wave absorption performance, Effects of increased resistivity and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a three-dimensional porous manganese oxide-cobalt composite electromagnetic wave absorbing material, comprising the following steps:

[0053] (1) with Co(CH 3 COO) 2 4H 2 O as cobalt source, Mn(CH 3 COO) 2 4H 2 O is used as a manganese source, and polyvinylpyrrolidone (PVP-K30) is used as a shape control agent and a dispersant. The above-mentioned cobalt source, manganese source, and PVP-K30 are added in 60mL of ethylene glycol solvent at an addition ratio of 2mmol:1mmol:0.6g, The obtained mixture was reacted at 200°C for 24 hours under airtight conditions; after the reaction was completed, the product was washed and dried at 60°C for 12 hours to obtain a manganese-cobalt hydroxide precursor;

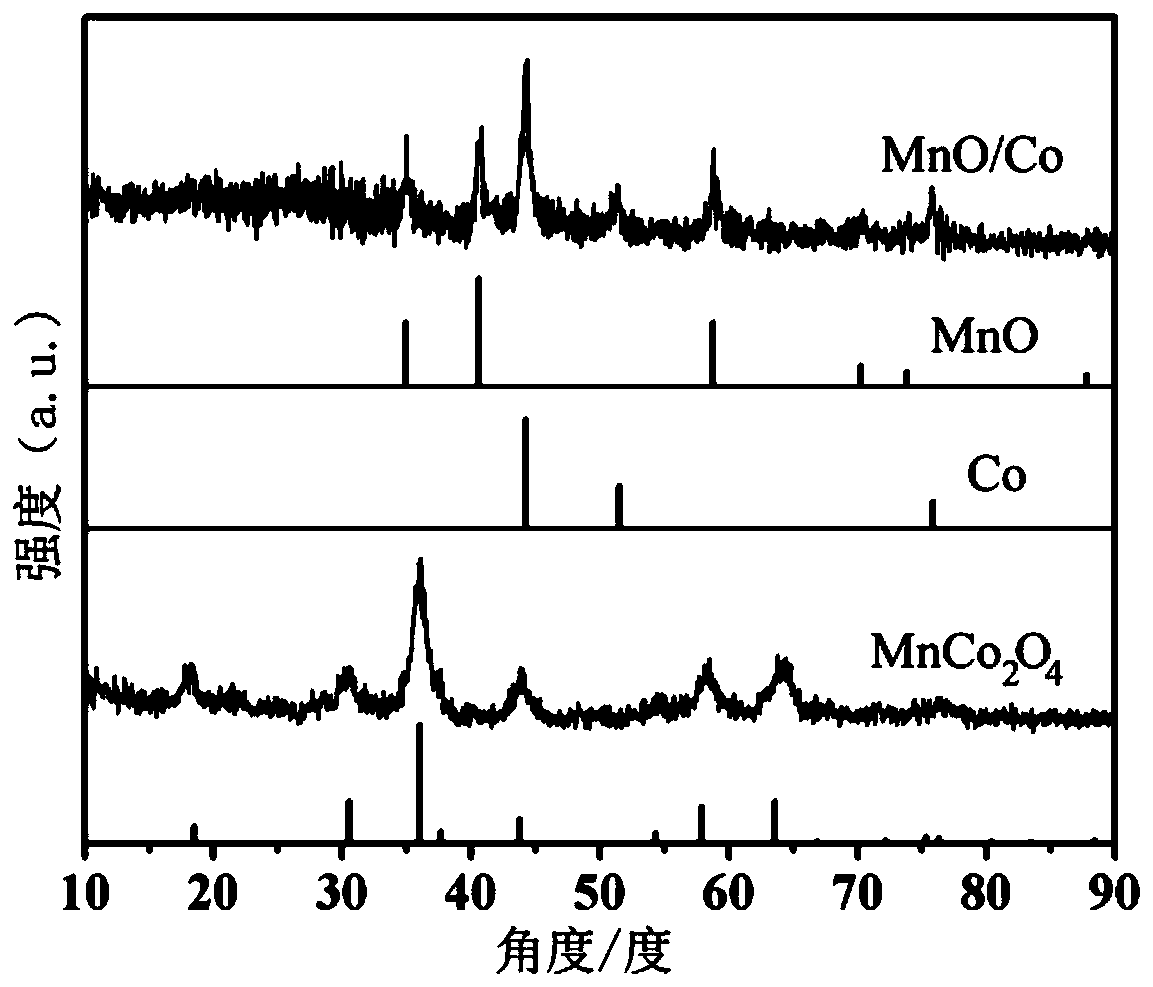

[0054] (2) Heat the manganese-cobalt hydroxide precursor prepared in step (1) at 400°C for 2 hours for calcination; after completion, place the calcined product in a tube furnace with a hydrogen flow rate of 30mL / min React at 450° C. for 1 hour, there...

Embodiment 2

[0061] Make electromagnetic wave absorber with the three-dimensional porous manganese oxide-cobalt composite electromagnetic wave absorbing material prepared in embodiment 1, and carry out test experiment, specifically as follows:

[0062] The composite electromagnetic wave absorbing material and paraffin are mixed according to the mass ratio of 80%: 20%, and then pressed into a ring-shaped sample (D 外 × d 内 ×h=7×3.04×2.0mm), related parameter μ r and ε r Measured with Agilent Technologies N5244A electromagnetic wave vector network analyzer, the reflection loss is measured by μ r , ε r , the absorption frequency and the thickness of the sample are determined, the results are as follows Figure 6 The electromagnetic wave absorption curve is shown as:

[0063] Measured ε r ' fluctuates very little in the frequency range of 2-18GHz, and its value is about 7.6.

[0064] Measured ε r "There are two formants with the same peak at 7-12GHz with a value of 0.5, and a smaller fo...

Embodiment 3

[0069] A method for preparing a three-dimensional porous manganese oxide-cobalt composite electromagnetic wave absorbing material, comprising the following steps:

[0070] (1) with CoCl 2 ·6H 2 O as cobalt source, MnCl 2 4H 2 O is used as a manganese source, and polyvinylpyrrolidone (PVP-K30) is used as a shape control agent and a dispersant. The above-mentioned cobalt source, manganese source, and PVP-K30 are added to 60mL of ethylene glycol solvent in a mass ratio of 1.5mmol:1.5mmol:1g In the process, the obtained mixture was reacted at 150° C. for 18 hours under airtight conditions; after the reaction was completed, the product was washed and dried to obtain a manganese-cobalt hydroxide precursor;

[0071] (2) Heat the manganese-cobalt hydroxide precursor prepared in step (1) at 600°C for 1 hour for calcination; after completion, place the calcined product in a tube furnace with a hydrogen flow rate of 35 mL / min. React at 350° C. for 2 hours, thereby reducing the mangan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com