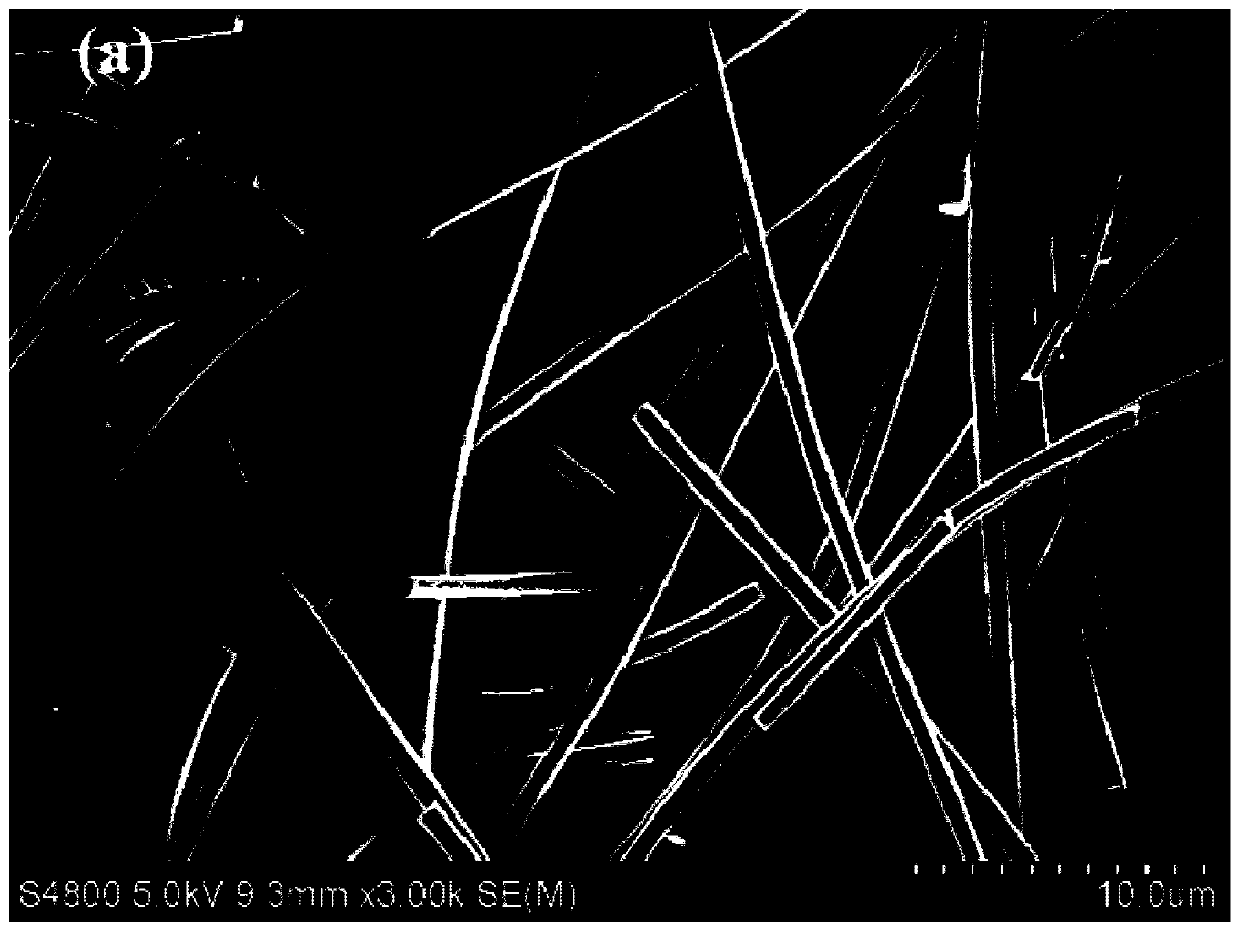

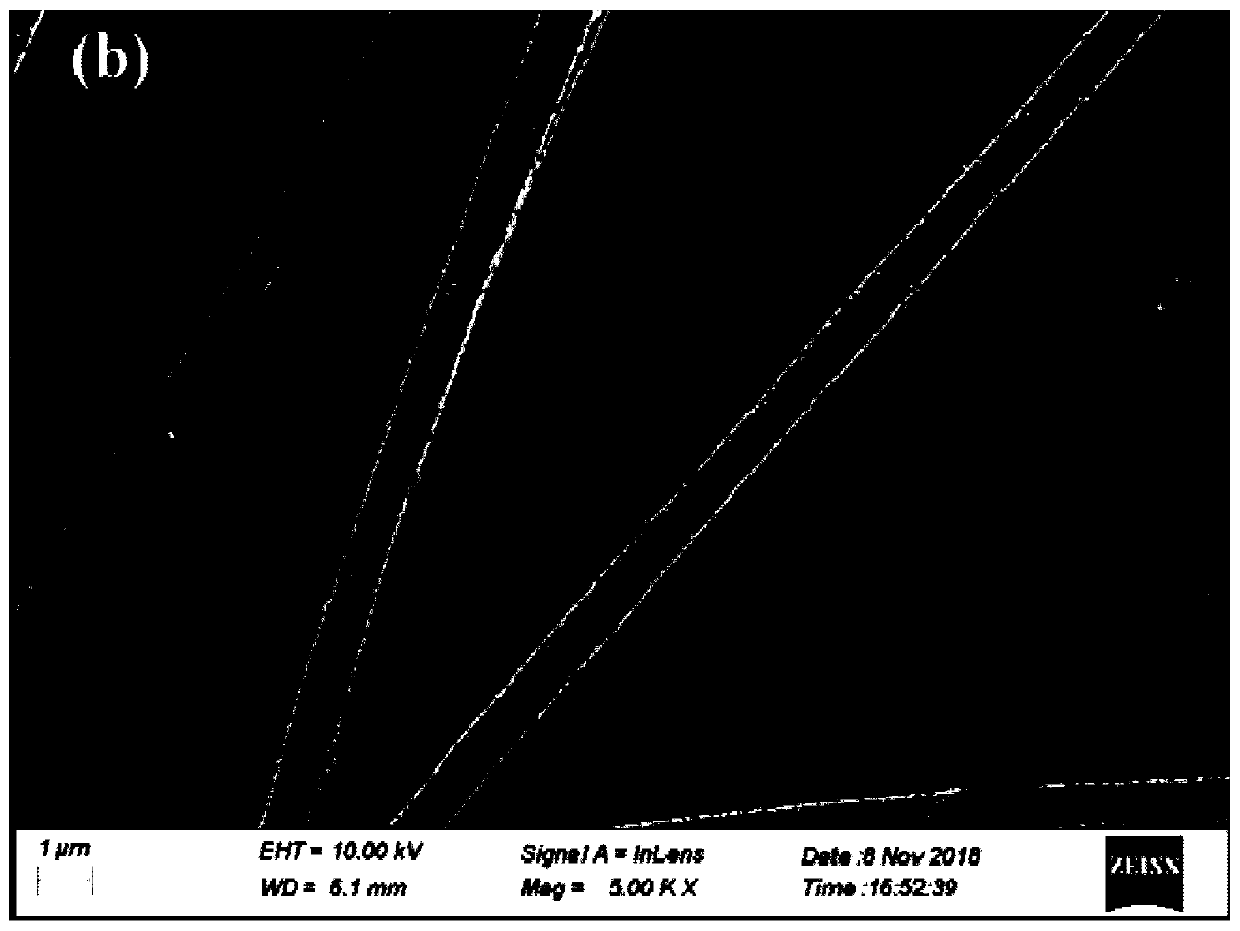

Flexible ferroferric oxide fibers and preparation method thereof

A technology of ferric oxide and ferric hydroxide, which is applied in the field of synthetic fibers, can solve the problems of uneven mixing of ferric oxide nanoparticles, limited dosing of ferric ferric oxide nanoparticles, and low saturation magnetization. The effect of poor flexibility, high saturation magnetization, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Technical scheme of the present invention is as follows:

[0010] A kind of preparation method of flexible ferroferric oxide fiber, comprises steps as follows:

[0011] (1) Weigh ferric salt and add it to deionized water, stir and dissolve, add dropwise alkaline solution until it is completely precipitated, centrifuge the precipitate and wash it with deionized water to prepare ferric hydroxide precipitate;

[0012] (2) According to the molar ratio of iron ion:acid source=1:1~3, weigh the newly prepared ferric hydroxide and acid source in step (1) respectively, add them into water at a temperature of 25~90°C and stir to react Dissolve and stir for 12-24 hours to obtain a clear solution;

[0013] (3) distilling the clear solution prepared in step (2) at 30-80°C under reduced pressure until a viscous sol is formed;

[0014] (4) adding a spinning aid to the sol obtained in step (3), and adjusting the viscosity with a solvent, stirring and dissolving at a temperature of 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com