Nano magnetic fluid composite material coated with polyamino acid and preparation method thereof

A polyamino acid and nano-magnetic fluid technology is applied in the field of magnetic fluid to achieve the effects of good crystallinity, strong hydrophilicity and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. take 0.2g molecular weight and be the solid powder polysuccinimide of 6000 in the Teflon reactor;

[0032] b. Dissolve 0.25g of NaOH solid powder in 25ml of deionized water, pour it into the Teflon reactor in step a after the NaOH is completely dissolved, stir and mix to dissolve completely;

[0033] c. 0.14g FeCl 3 ·6H 2 O (0.5mmol) and 0.39g Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 Add O (1mmol) into 10ml of deionized water, stir to dissolve, mix with the solution obtained in step b, and continue stirring for 5-15 minutes; seal the Teflon reactor with a stainless steel sleeve, and react at 140°C for 2 hours;

[0034] d. Discard the supernatant after cooling, collect the lower solid by magnetic separation, dissolve it in water, add ethanol to precipitate and centrifuge and wash 2-5 times, and finally disperse the product stably in 5-10ml deionized water, that is, polyamino acid coated Ferroferromagnetic nanoparticle composite material.

Embodiment 2

[0036] a. take 0.2g molecular weight and be the solid powder polysuccinimide of 6000 in the Teflon reactor;

[0037] b. Dissolve 0.25g of NaOH solid powder in 25ml of deionized water, pour it into the Teflon reactor in step a after the NaOH is completely dissolved, stir and mix to dissolve completely;

[0038] c. 0.14g FeCl 3 ·6H 2 O (0.5mmol) and 0.39g Fe(NH 4 ) 2 (SO4) 2 ·6H 2 Add O (1mmol) into 10ml of deionized water, stir to dissolve, mix with the solution obtained in step b, and continue to stir for 5-15 minutes; seal the Teflon reactor with a stainless steel sleeve, and react at 150°C for 2 hours;

[0039] d. Discard the supernatant after cooling, collect the lower solid by magnetic separation, dissolve it in water, add ethanol to precipitate and centrifuge and wash 2-5 times, and finally disperse the product stably in 5-10ml deionized water, that is, polyamino acid coated Ferroferromagnetic nanoparticle composite material.

Embodiment 3

[0041] a. take 0.2g molecular weight and be the solid powder polysuccinimide of 6000 in the Teflon reactor;

[0042] b. Dissolve 0.25g of NaOH solid powder in 25ml of deionized water, pour it into the Teflon reactor in step a after the NaOH is completely dissolved, stir and mix to dissolve completely;

[0043] c. 0.14g FeCl 3 ·6H 2 O (0.5mmol) and 0.39g Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 Add O (1mmol) into 10ml of deionized water, stir to dissolve, mix with the solution obtained in step b, and continue to stir for 5-15 minutes; seal the Teflon reactor with a stainless steel sleeve, and react at 160°C for 2 hours;

[0044] d. Discard the supernatant after cooling, collect the lower solid by magnetic separation, dissolve it in water, add ethanol to precipitate and centrifuge and wash 2-5 times, and finally disperse the product stably in 5-10ml deionized water, that is, polyamino acid coated Ferroferromagnetic nanoparticle composite material.

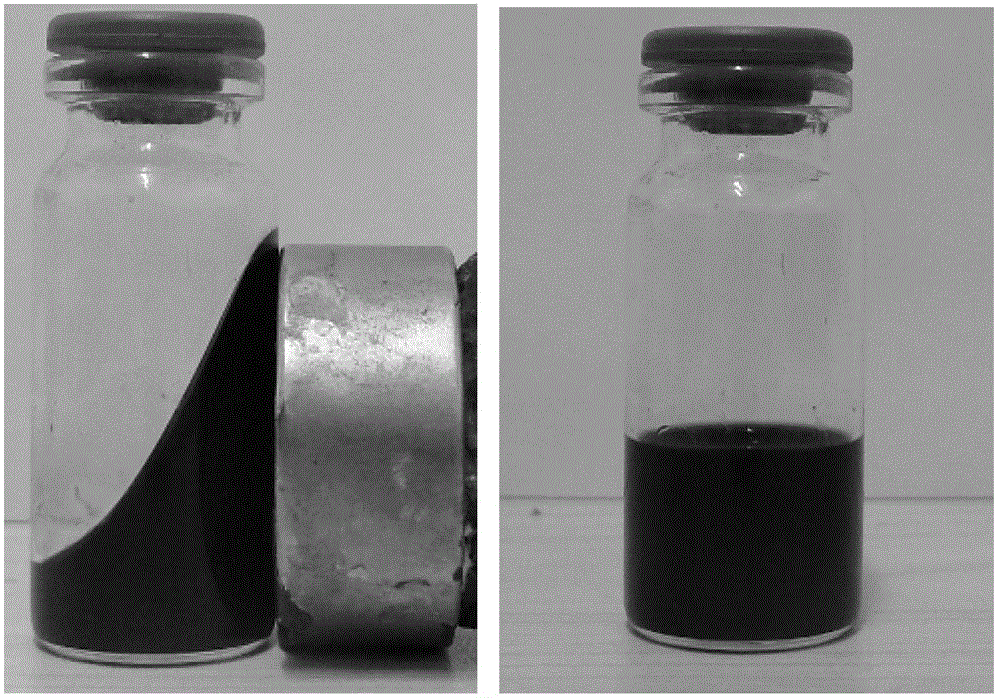

[0045] The state (left) and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com