Method for preparing unsaturated polyester resin used in putty

A technology of polyester resin and unsaturated fatty acid, which is applied in the field of preparation of unsaturated polyester resin, and can solve the problem of shortening the curing time of the resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

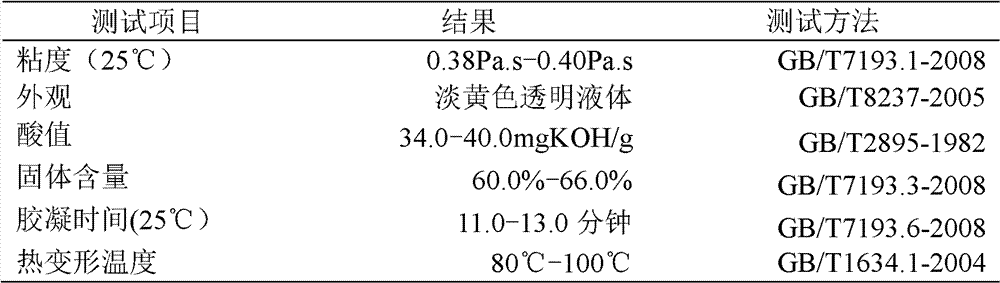

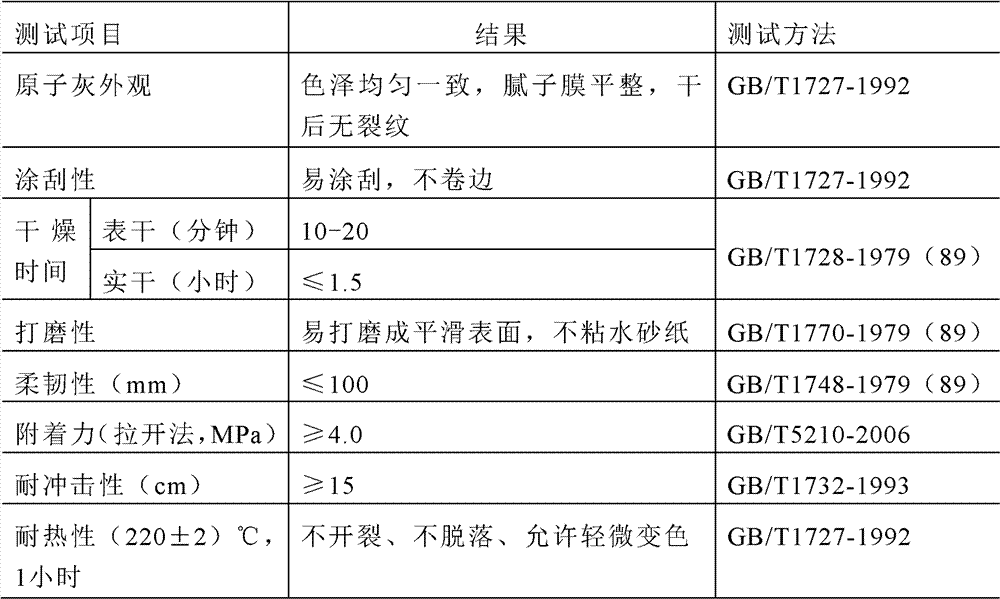

Image

Examples

Embodiment 1

[0019] Prepare the unsaturated polyester resin for putty as follows:

[0020] 1) Using linseed oil, linseed oleic acid and trimethylolpropane to synthesize macromolecular air-drying alcohol

[0021] Put in 1500g of linseed oil, then add 465g of trimethylolpropane and 0.6g of lithium hydroxide, stir for 10 minutes, gradually raise the temperature of the reaction materials to 175°C-185°C, and fully mix the reaction materials with 3 times the volume of methanol , when the resulting liquid is transparent, that means the reaction is complete.

[0022] 2) Synthetic soft resin

[0023] Put in 1280g diethylene glycol, 395g adipic acid and 895g isophthalic acid, stir to disperse evenly, then gradually raise the temperature to 215°C-220°C for reaction, when the solid acid value is below 50mgKOH / g, cool down to 160°C and add 395g Maleic anhydride, and continue to heat up to 215°C-220°C, react until the acid value of the liquid is 10-14mgKOH / g (test ratio: polyester / styrene=17 / 8). Cool...

Embodiment 2

[0027] Prepare the unsaturated polyester resin for putty as follows:

[0028] 1) Using linseed oil, linseed oleic acid and trimethylolpropane to synthesize macromolecular air-drying alcohol

[0029] Put in 1600g of linseed oil, then add 480g of trimethylolpropane and 1.2g of lithium hydroxide, stir for 10 minutes, gradually raise the temperature of the reaction materials to 175°C-185°C, and fully mix the reaction materials with 3 times the volume of methanol , when the resulting liquid is transparent, that means the reaction is complete.

[0030] 2) Synthetic soft resin

[0031] Put in 1250g diethylene glycol, 110g ethylene glycol, 415g adipic acid and 905g isophthalic acid, stir to disperse evenly, then gradually raise the temperature to 215°C-220°C for reaction, when the solid acid value is below 50mgKOH / g, cool down Add 395g of maleic anhydride to 160°C, and continue to heat up to 215°C-220°C, react until the acid value of the liquid is 10-14mgKOH / g (test ratio: polyester...

Embodiment 3

[0035] Prepare the unsaturated polyester resin for putty as follows:

[0036] 1) Using linseed oil, linseed oleic acid and trimethylolpropane to synthesize macromolecular air-drying alcohol

[0037] Put in 1600 g of linseed oleic acid, then add 480 g of trimethylolpropane and 1.2 g of lithium hydroxide, stir for 10 minutes, gradually raise the temperature of the reaction material to 175°C-185°C, and fully mix the reaction material with 3 times the volume of methanol When the resulting liquid is transparent, it indicates that the reaction is complete.

[0038] 2) Synthetic soft resin

[0039] Put in 1250g diethylene glycol, 110g ethylene glycol, 415g adipic acid and 905g isophthalic acid, stir to disperse evenly, then gradually raise the temperature to 215°C-220°C for reaction, when the solid acid value is below 50mgKOH / g, cool down Add 395g of maleic anhydride to 160°C, and continue to heat up to 215°C-220°C, react until the acid value of the liquid is 10-14mgKOH / g (test ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com