Method for preparing black perylene derivatives pigment

A pigment and perylene-based technology, which is applied in the field of preparation of black perylene-based pigments, can solve the problems of high cost, high manufacturing cost, flammability and explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

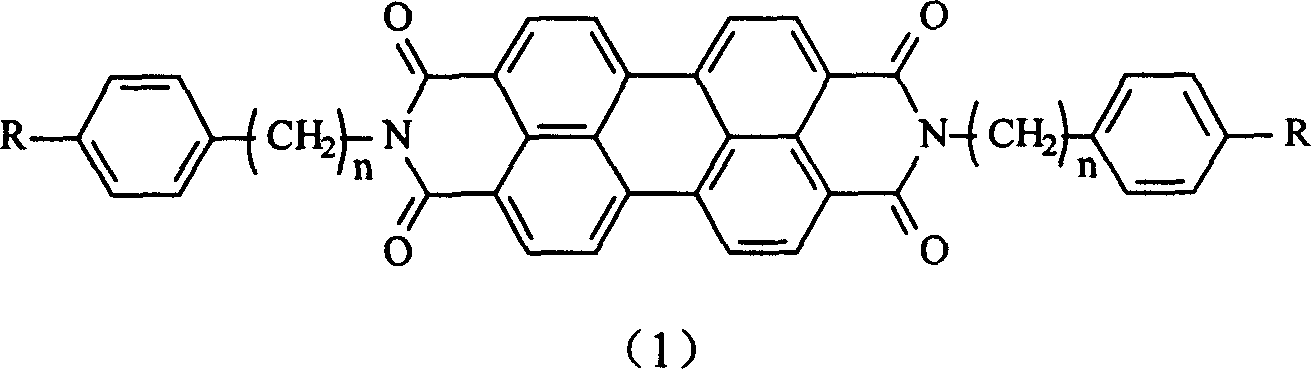

[0034] Preparation of N, N'-diphenylethylperylene tetraimide (C.I. Pigment Black 31)

[0035] 1) Synthesis of crude pigment:

[0036] Add 120g (0.3mol) 3,4,9,10-perylenetetraacid dianhydride in 1200g 10% KOH, heat to make it dissolve completely, cool to room temperature and add 89g (0.75mol) phenethylamine, after stirring evenly, Then add 160g of acetic acid, mix evenly, transfer the material to the autoclave, seal it, raise the temperature to 130-135°C (about 5 atmospheres), heat and stir for 5h, and take a sample for detection. If the perylene anhydride in the reactant is basically exhausted, then After the reaction was completed, it was cooled to room temperature, filtered, washed with water until neutral, and dried to obtain 180 g of a black solid, that is, N, N'-diphenylethylperylene tetraimide, and the yield was close to 100%.

[0037] 2) Pigmentation of crude pigments:

[0038] Put the dry 60g crude product pigment prepared by the above method into a ball mill, add 45...

Embodiment 2

[0040] Preparation of N, N'-diphenylethylperylene tetraimide (C.I. Pigment Black 31)

[0041] 1) Synthesis of crude pigment:

[0042] In a stainless steel reaction kettle, add 800g of glycerol, add 120g (0.3mol) of 3,4,9,10-perylenetetraic acid dianhydride and 89g (0.75mol) of phenylethylamine under stirring, and heat up to 170-175°C. Keep stirring for 1h. Sampling and detection, if the perylene anhydride in the reactant is basically exhausted, the reaction ends. Cool to 50°C, dilute with 300g of methanol, filter at 40°C, wash with methanol, then wash with water, and dry to obtain 160g of black crystals, that is, N,N'-diphenylethylperylene tetraimide, yield 90 %.

[0043] 2) Pigmentation of crude pigments:

[0044] Same example 1

Embodiment 3

[0046] Preparation of N,N'-bis(4'-methoxybenzyl)perylene tetraimide (C.I. Pigment Black 32)

[0047] 1) Synthesis of crude pigment:

[0048] In the stainless steel reactor, add 1500g glycerol, add 120g (0.3mol) 3,4,9,10-perylenetetraic acid dianhydride and 102g (0.75mol) 4-methoxybenzylamine under stirring, be warming up to 170 ~175°C, keep stirring for 1h. Sampling and detection, if the perylene anhydride in the reactant is basically exhausted, the reaction ends. Cool to 50°C, dilute with 800g of methanol, filter at 40°C, wash with methanol, then water, and dry to obtain 174g of black crystals, that is, N,N'-bis(4'-methoxybenzyl)perylenetetraacid di Imide, 97% yield.

[0049] 2) Pigmentation of crude pigments:

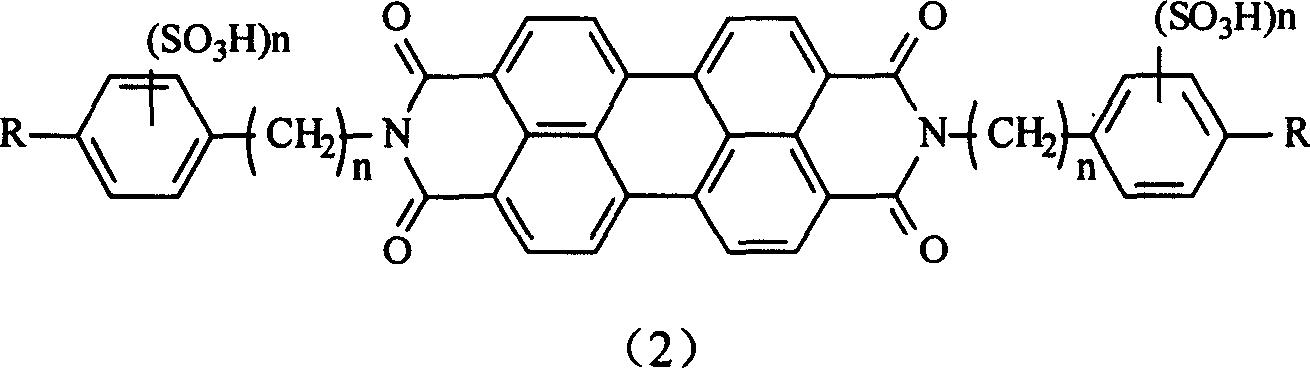

[0050] Put the dried 60g crude product pigment prepared by the above method into a ball mill, add 450g steel balls, a mixture of 240g sodium chloride and sodium sulfate (1:1), 2g calcium stearate and 1.2gN,N'-di Phenylethyl perylene tetraimide disulfonic acid, ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com