Low-temperature preparation method of hydroxy-functionalized graphene

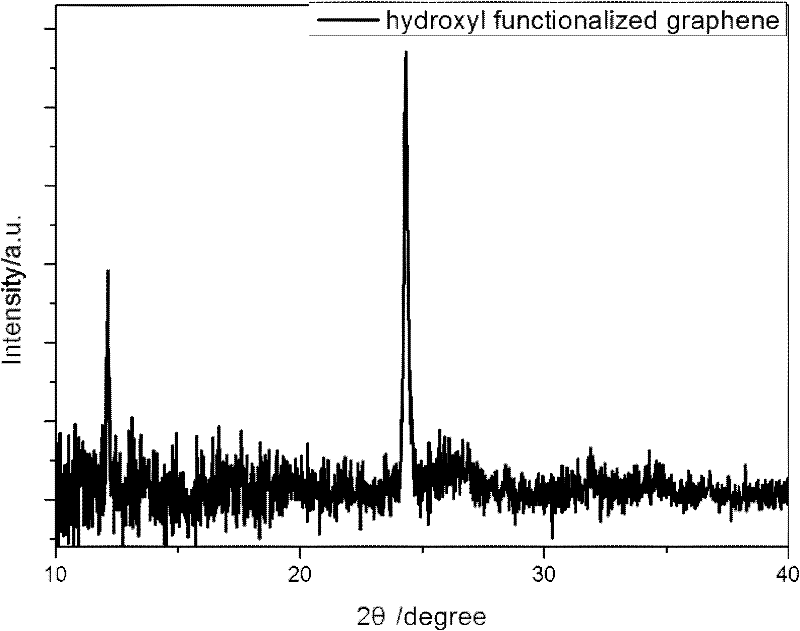

A functional and fossil technology, applied in nanotechnology and other directions, can solve problems such as high risk and achieve the effect of high degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Add 10mg of -100 mesh flake graphite powder and 200mg of potassium hydroxide solid into a 250ml agate ball milling tank, add dry agate balls with a diameter of 3mm for ball milling, and the amount added is about 30% of the volume of the agate ball milling tank one fifth. Then put the ball mill jar into the ball mill, under the condition of air blast and normal temperature, ball mill continuously at a speed of 200-400 rpm for 10-16 hours, then transfer the ball mill product to a 20ml sample bottle with 10ml of deionized water . Then put it into a dialysis bag and repeatedly replace deionized water to remove unreacted potassium hydroxide until the solution is neutral. Hydroxygraphene with good dispersibility is obtained.

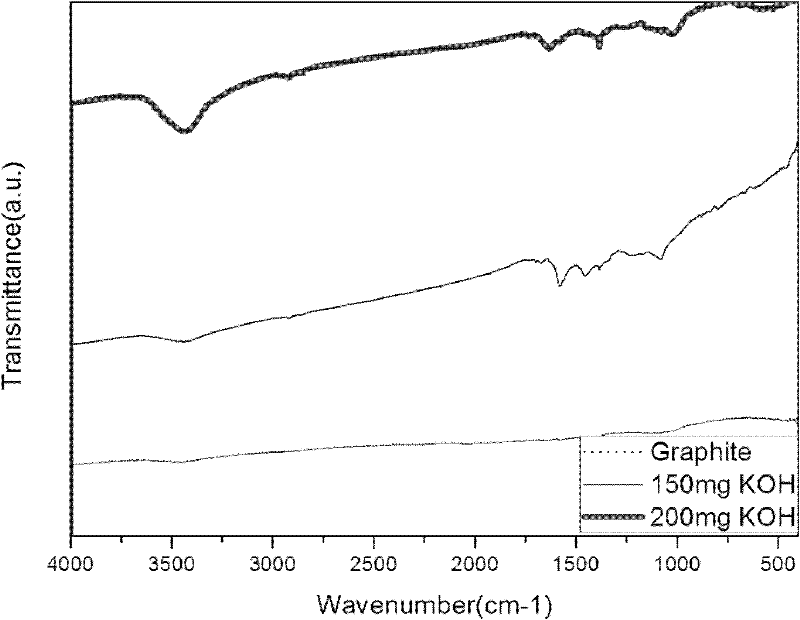

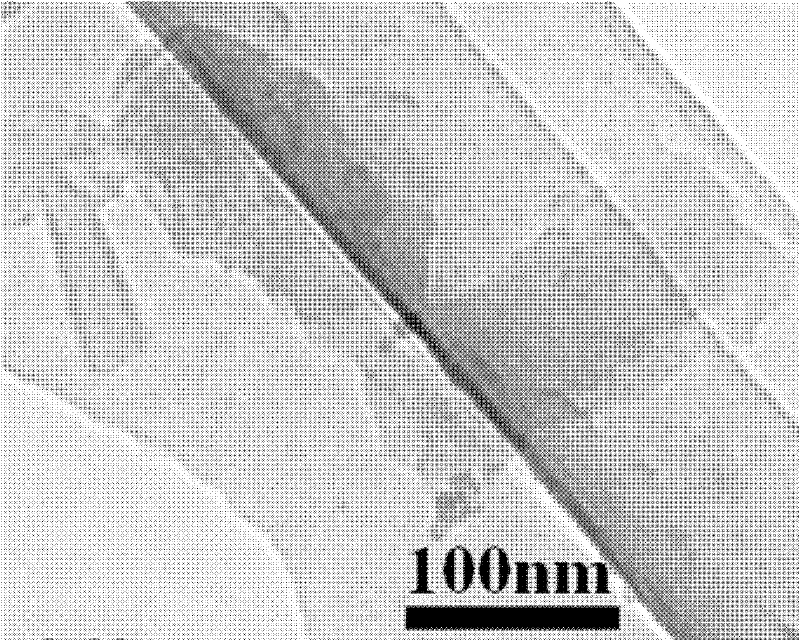

[0019] The dispersion liquid was dropped on a flat single crystal silicon wafer, put into a vacuum drying oven with a vacuum degree of 0.1 Pa, and dried overnight. The chemical structure of the graphene surface was measured by Fourier transform infra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com