Hydroxylated graphene as well as preparation method and application thereof

A technology of hydroxylated graphene and graphene, applied in the field of nanomaterials, can solve the problems of hydroxylated graphene containing impurity functional groups, difficult separation and unenvironmental protection, long reaction time, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

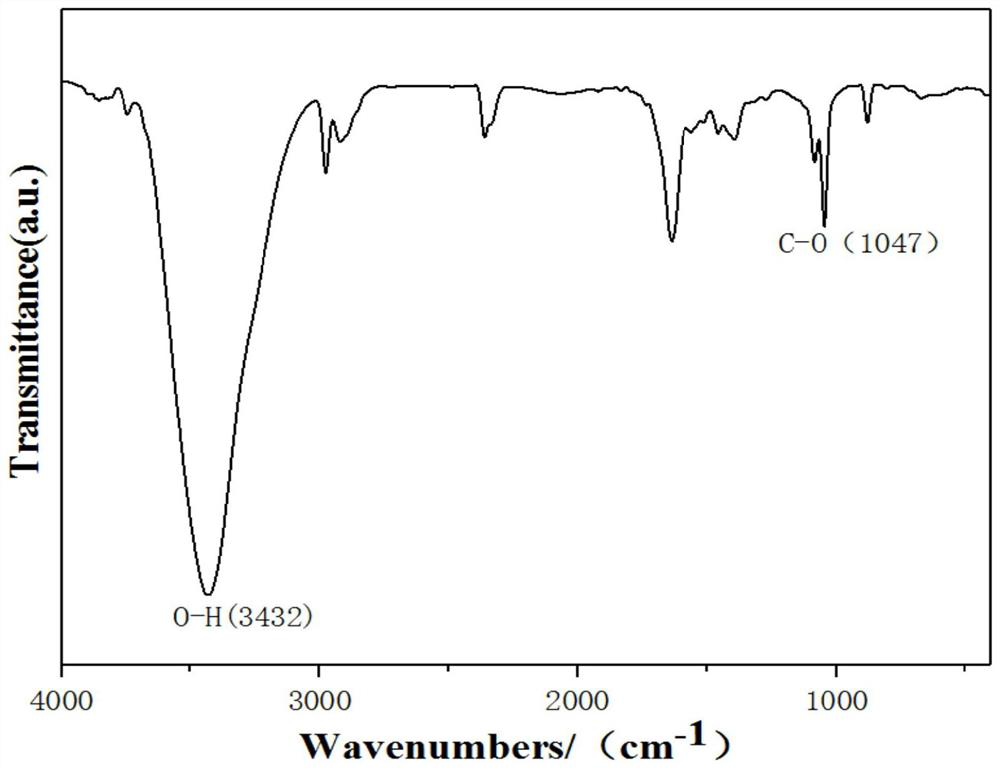

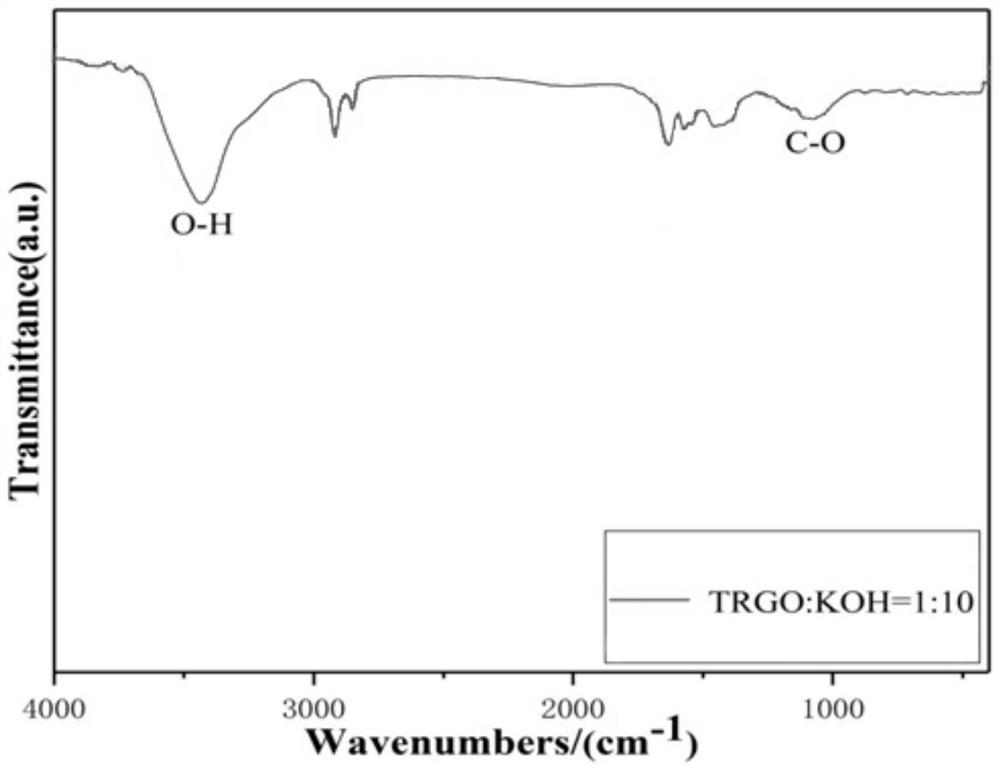

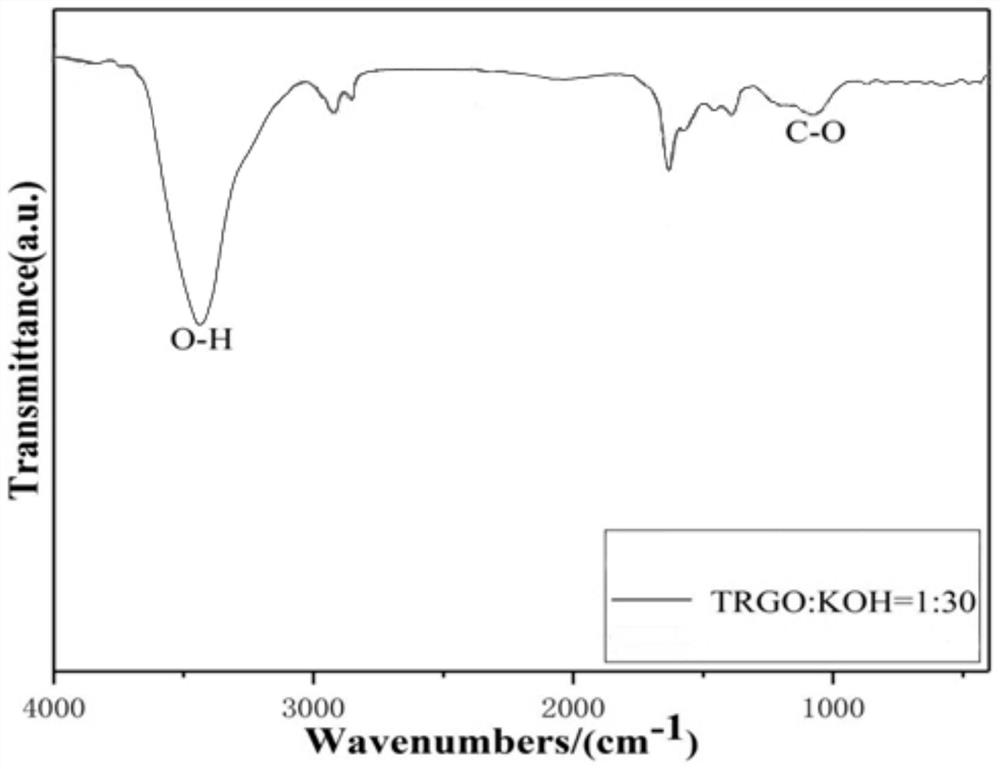

Image

Examples

Embodiment 1

[0031] A preparation method for hydroxylated graphene, comprising the following steps:

[0032] S0: Weigh 10g of graphite oxide and place it in a crucible, put it into the quartz tube of the tube furnace, then pass argon gas into the quartz tube to purge for 30min, and maintain the temperature after the tube furnace is heated to 500°C. Temperature, keep the quartz tube in a high-temperature tube furnace for 5 minutes, and make graphite oxide carry out high-temperature reaction to prepare thermally reduced graphene oxide (TRGO) with a porous structure. In particular, in the whole preparation process of TRGO, it should be The quartz tube was continuously filled with argon.

[0033] Specifically, the thermally reduced graphene oxide with a porous structure prepared at high temperature has a lateral size of 2-8um, and the diameter of the nanopores on the nanosheet is 1-5nm, so the thermally reduced graphene oxide with a porous structure has a high ratio surface area.

[0034]S1:...

Embodiment 2

[0040] A preparation method for hydroxylated graphene, comprising the following steps:

[0041] S0: Weigh 10g of graphite oxide and place it in a crucible, put it into the quartz tube of the tube furnace, and then blow nitrogen into the quartz tube for 30min, and maintain the temperature after the tube furnace is heated to 800°C , keep the quartz tube in a high-temperature tube furnace for 5 minutes, and make graphite oxide react at a high temperature to produce thermally reduced graphene oxide (TRGO) with a porous structure. In particular, during the entire preparation process of TRGO, the quartz The tube was continuously filled with nitrogen.

[0042] Specifically, the thermally reduced graphene oxide with a porous structure prepared at high temperature has a lateral size of 2-8um, and the diameter of the nanopores on the nanosheet is 1-5nm, so the thermally reduced graphene oxide with a porous structure has a high ratio surface area.

[0043] S1: The heat-reduced graphene...

Embodiment 3

[0052] A preparation method for hydroxylated graphene, comprising the following steps:

[0053] S0: Weigh 10g of graphite oxide and place it in a crucible, and put it into the quartz tube of the tube furnace, then blow nitrogen into the tube for 30 minutes, and maintain the temperature after the tube furnace is heated to 1000°C , keep the quartz tube in a high-temperature tube furnace for 5 minutes, and make graphite oxide react at a high temperature to produce thermally reduced graphene oxide (TRGO) with a porous structure. In particular, during the entire preparation process of TRGO, the quartz The tube was continuously filled with nitrogen.

[0054] Specifically, the thermally reduced graphene oxide with a porous structure prepared at high temperature has a lateral size of 2-8um, and the diameter of the nanopores on the nanosheet is 1-5nm, so the thermally reduced graphene oxide with a porous structure has a high ratio surface area.

[0055] S1: The heat-reduced graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com