Iron sesquioxide nanotube material as well as preparation method and application thereof

A ferric oxide and nanotube technology, applied in nanotechnology, nanotechnology, secondary battery manufacturing, etc., can solve problems such as poor cycle life and low coulombic efficiency, achieve good reproducibility, improve coulombic efficiency, and be suitable for The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 0.822g of ferric chloride and 1.234g of fumaric acid to a beaker containing 80ml of deionized water, and keep stirring at a speed of 800r / min until all are dissolved;

[0029] (2) Place the mixed aqueous solution in step (1) in a 100 mL autoclave, and then place it in an oven for hydrothermal treatment, keep it at 70°C for 24 hours, and then cool it naturally to room temperature;

[0030] (3) The sample after hydrothermal in step (2) is centrifuged at 6000r / min and washed with ethanol and deionized water for 3 times; finally, the precipitate is dried in a vacuum drying at 80°C to obtain iron Metal-based organic framework nanofibers.

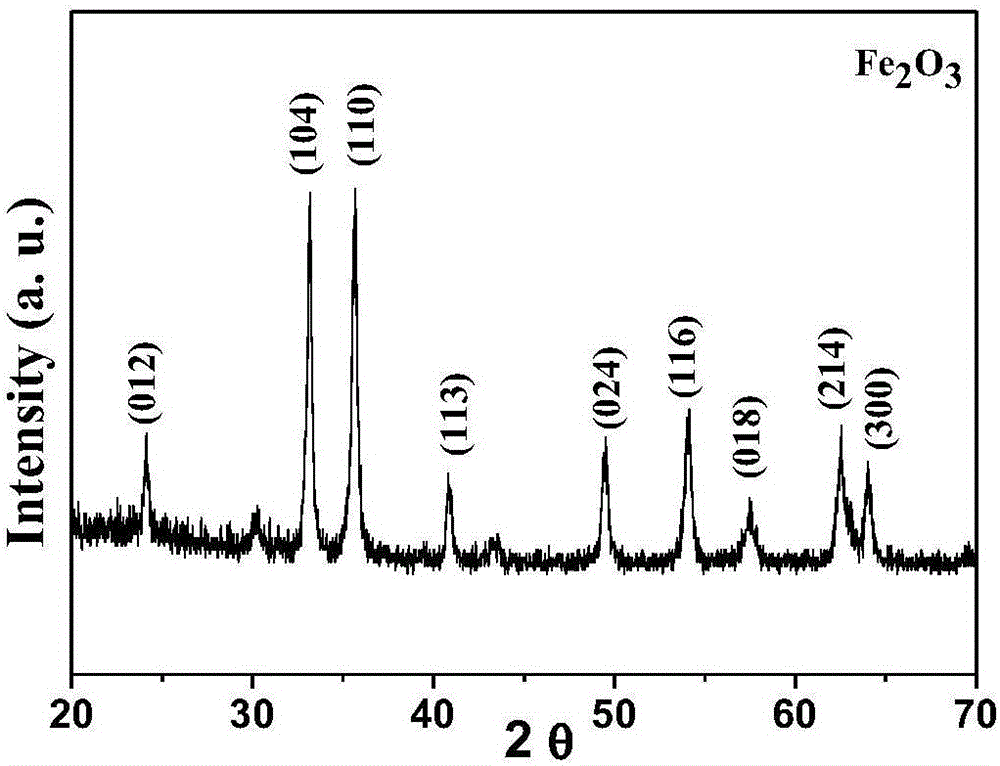

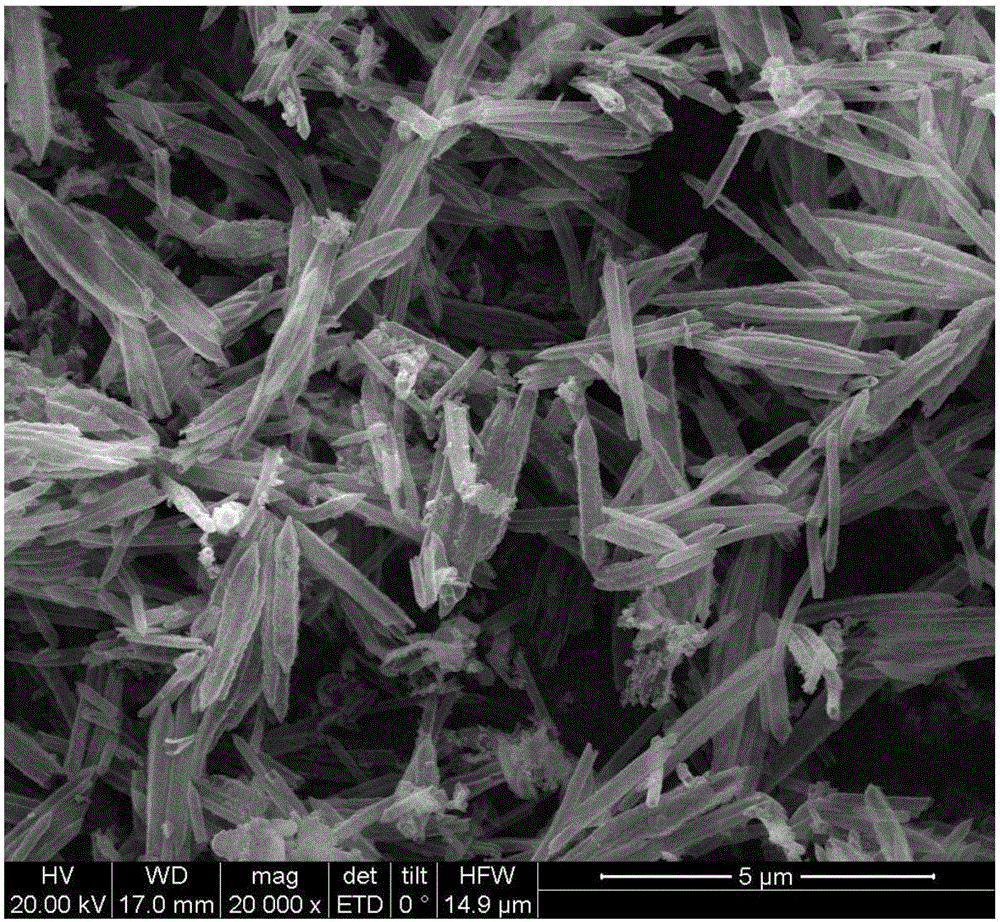

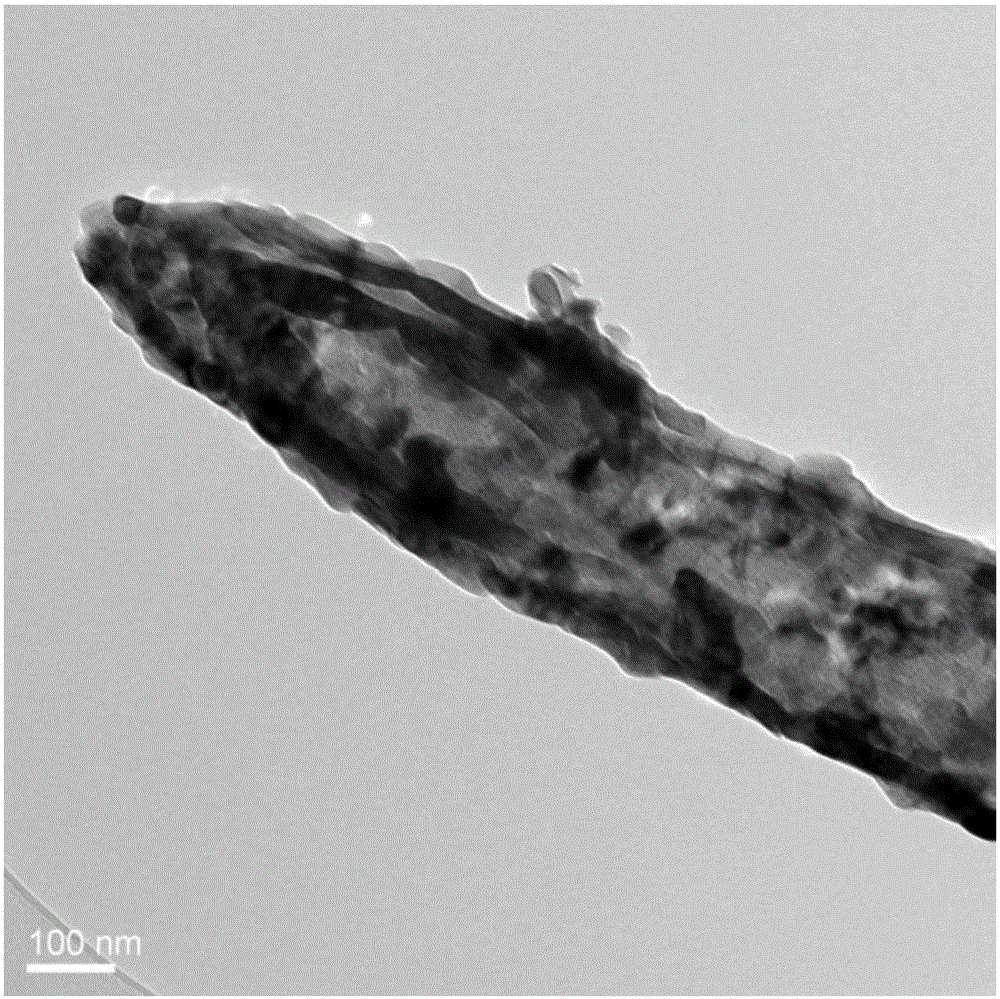

[0031] (4) Put the iron-based metal-organic framework nanofibers dried in step (3) in a tube furnace, and pass air shielding gas at an air intake of 0.15L / min. The heating rate is 2℃ / min, and the temperature is increased to After being kept at 550°C for 4 hours, it is naturally cooled to room temperature to obtain the ferric oxide nanotu...

Embodiment 2

[0034] (1) Add 1.112g ferric nitrate and 1.112g fumaric acid to a beaker containing 80ml deionized water, and stir continuously at a speed of 700r / min until all are dissolved;

[0035] (2) Place the mixed aqueous solution in step (1) in a 100mL autoclave, and then place it in an oven for hydrothermal treatment, keep it at 80°C for 24 hours and then cool it naturally to room temperature;

[0036] The other steps are the same as in Example 1.

Embodiment 3

[0038] (1) Add 0.741g of iron sulfate and 1.334g of fumaric acid to a beaker containing 80ml of deionized water and stir continuously at a speed of 900r / min until all are dissolved;

[0039] (2) Place the mixed aqueous solution in step (1) in a 100mL autoclave, and then place it in an oven for hydrothermal treatment, keep it at 75°C for 24 hours, and then cool to room temperature naturally;

[0040] The other steps are the same as in Example 1.

[0041] Table 1 shows the capacity of the lithium ion batteries of Examples 1 to 3 in the first cycle and the 50th cycle of the charge-discharge test at a current of 0.1C.

[0042] Table 1

[0043]

[0044] It can be seen from Table 1 that the ferric oxide nanotubes prepared by this method are used as electrode materials and applied to lithium-ion batteries. After 50 cycles of cycles, the capacity retention rate is above 88.4%, which has good cycle performance and is still high. For the current commercial graphite anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com